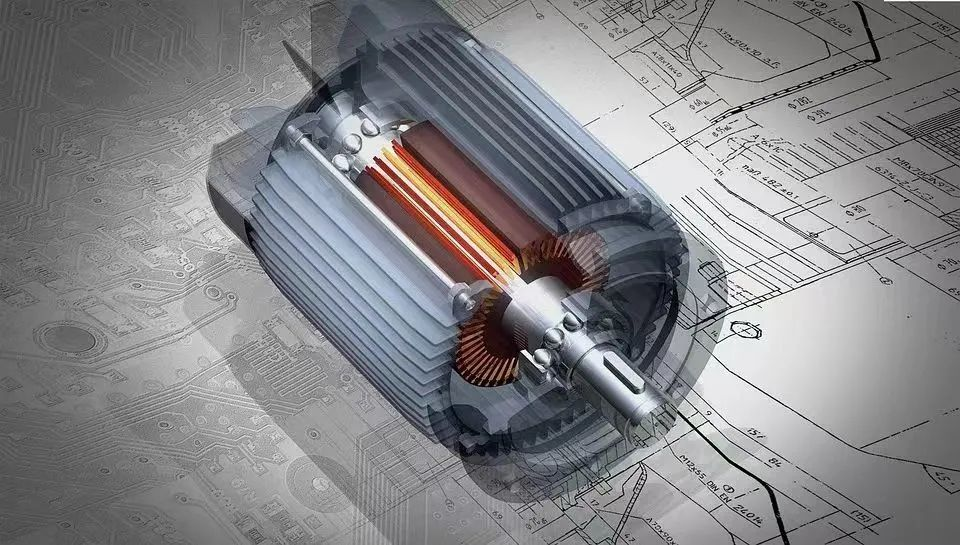

Classification of motor stator and rotor windings and 7 stator winding methods!

01

Magnetic pole division with stator windings

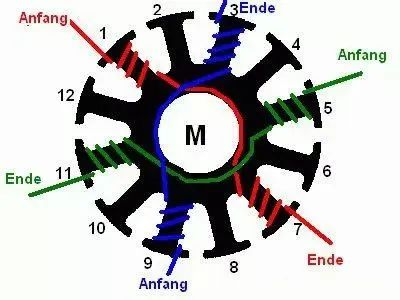

According to the relationship between the number of magnetic poles of the motor and the distribution of the windings to form the actual number of magnetic poles, the stator winding can be divided into two types: explicit pole type and common pole type.

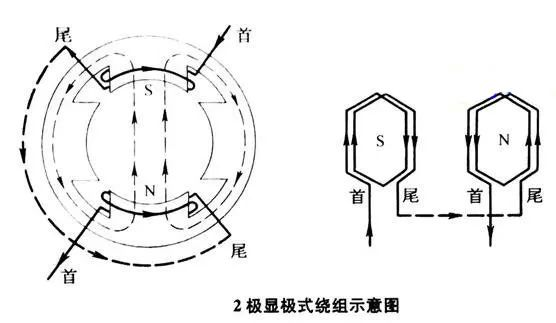

Significant winding

In a significant pole winding, each group of coils forms a magnetic pole, and the number of coils in the winding is equal to the number of magnetic poles.

In the significant pole winding, in order to make the polarities N and S of the magnetic poles spaced apart from each other, the current directions in the two adjacent coils must be opposite, that is, the connection mode of the two adjacent coils must be connected to the tail end and the first end to the end. The head end (the electrician's term is "tail joint, head joint") , that is, the reverse connection series method .

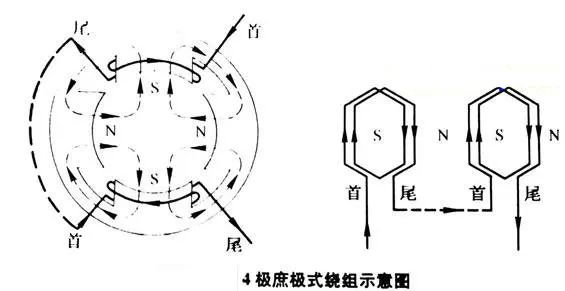

common pole winding

In a common-pole winding, each coil forms two magnetic poles, and the number of coils in the winding is half the number of magnetic poles, because the other half of the magnetic poles are jointly formed by the magnetic lines of force generated by the coils.

In the common-pole winding, the polarity of the magnetic poles formed by each coil is the same, so the current direction in all the coils is the same, that is, the connection mode of two adjacent coils should be the tail end to the head end (the electrical term is "Tail joint") , that is, in series .

02

In the shape of the stator winding

Distinction from embedded wiring

The stator winding can be divided into two types: centralized and distributed according to the shape of the coil winding and the way of embedded wiring.

Concentrated winding

Concentrated windings generally consist of only one or several rectangular frame coils. After winding, it is wrapped with gauze tape to set the shape, and then it is embedded in the iron core of the convex magnetic pole after being soaked in paint and dried. This type of winding is used in the excitation coils of DC motors, general-purpose motors, and the main pole windings of single-phase shaded pole motors .

distributed winding

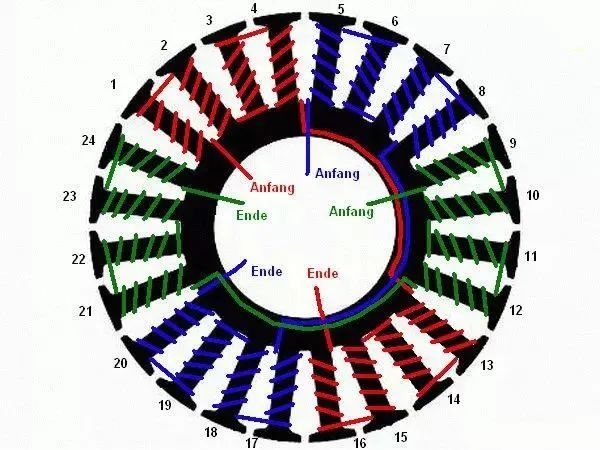

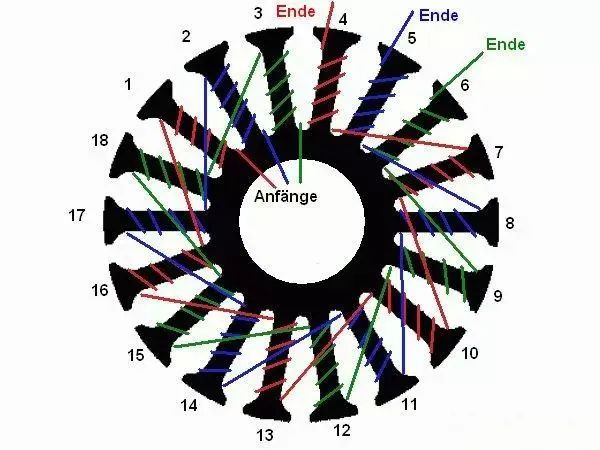

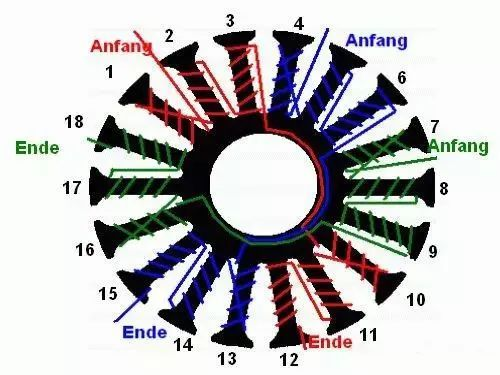

The motor stator with distributed winding has no convex pole palm, and each magnetic pole is composed of one or several coils embedded and wired according to certain rules to form a coil group. According to the different forms of embedded wiring arrangements, distributed windings can be divided into two types: concentric and stacked.

concentric winding

The concentric winding is several rectangular coils of different sizes in the same coil group, which are embedded one by one at the same center and arranged in a zigzag pattern. Concentric windings are divided into single-layer and multi-layer.

The stator windings of general single-phase motors and some low-power three-phase asynchronous motors adopt this type.

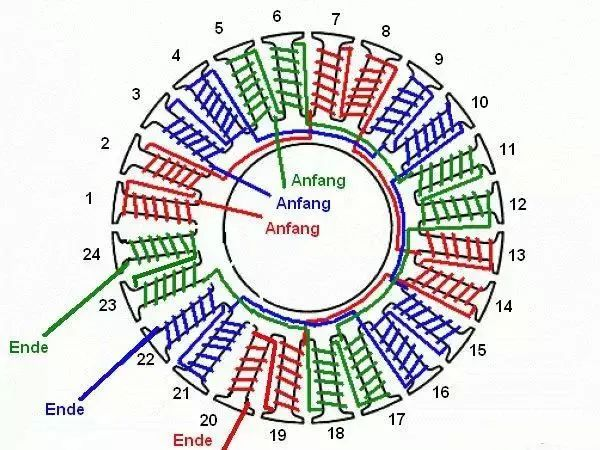

stacked winding

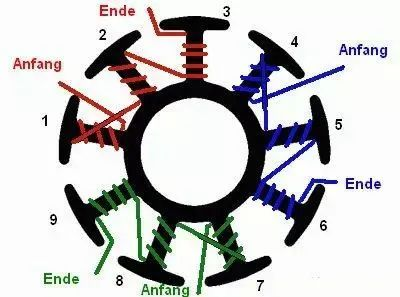

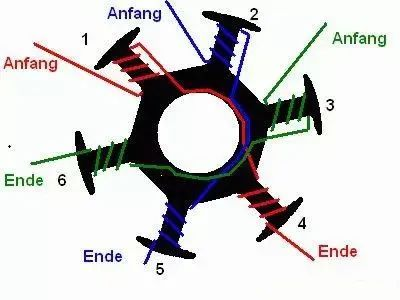

Laminated winding is a type in which all coils have the same shape and size (except for single and double coils) , one coil side is embedded in each slot, and the outer ends of the slots are stacked and evenly distributed one by one. Stacked windings are divided into two types : single-layer stacked and double-layer stacked .

Only one coil side is embedded in each slot, which is called single-layer stacked winding, or single-stacked winding; each slot is embedded with two coil sides belonging to different coil groups (divided into upper and lower layers), which is called double-layer stacked winding, or double-layered winding . stack winding.

Due to the different changes in the embedded wiring method, the stacked winding can be divided into a single double-turn cross wiring arrangement and a single double-layer mixed wiring arrangement;

In addition, the embedded shape from the end of the winding is called chain winding and basket winding, which are actually stacked windings. Generally, the stator windings of three-phase asynchronous motors use stacked windings .

03

rotor winding

Rotor windings are basically divided into two types: squirrel-cage type and wire-wound type. The squirrel-cage structure is relatively simple. Its windings used to be embedded with copper bars. At present, most of them are cast aluminum. The special double-squirrel-cage rotor has two sets of squirrel-cage bars.

The wound rotor winding is the same as the stator winding, and it is also divided into stacked and wave windings .

The shape of the wave winding is similar to that of the stacked winding, but the wiring method is different. Its basic element is not the whole coil, but a single-turn unit coil, which needs to be welded into coil groups one by one after embedding.

Waveform windings are generally used in rotor windings of large AC motors or armature windings of medium and large DC motors.

04

7 stator winding methods

XINDA

XINDA