What materials and architectures will be used in the next generation of advanced motors?

Under the dual-carbon strategic layout, drive motors, as the core components of new energy vehicles, need to pay more attention to the development of high efficiency, miniaturization, and intelligence. In recent years, in order to further improve the core indicators such as power density and efficiency of the drive motor and reduce costs, motor companies continue to develop high-performance motor products, less/no heavy rare earth permanent magnets, 6.5% Si high silicon steel, soft magnetic composite materials, amorphous Key materials such as /nanocrystalline alloys have received much attention. In addition, although centralized drive is the current mainstream, distributed drive technologies such as wheel motors and in-wheel motors have always been research hotspots because of their advantages such as short transmission paths and independent control of inter-axle or inter-wheel torque.

However, the development of new drive motors also faces some problems. For example, some key materials of innovative drive motors still have pain points such as difficult process and high cost. Distributed drives, especially hub drives, still have problems such as poor controllability, high cost, and low reliability. Further verification is needed to promote the application on more car models.

The following is mainly from the two dimensions of advanced materials for drive motors and distributed drives .

-

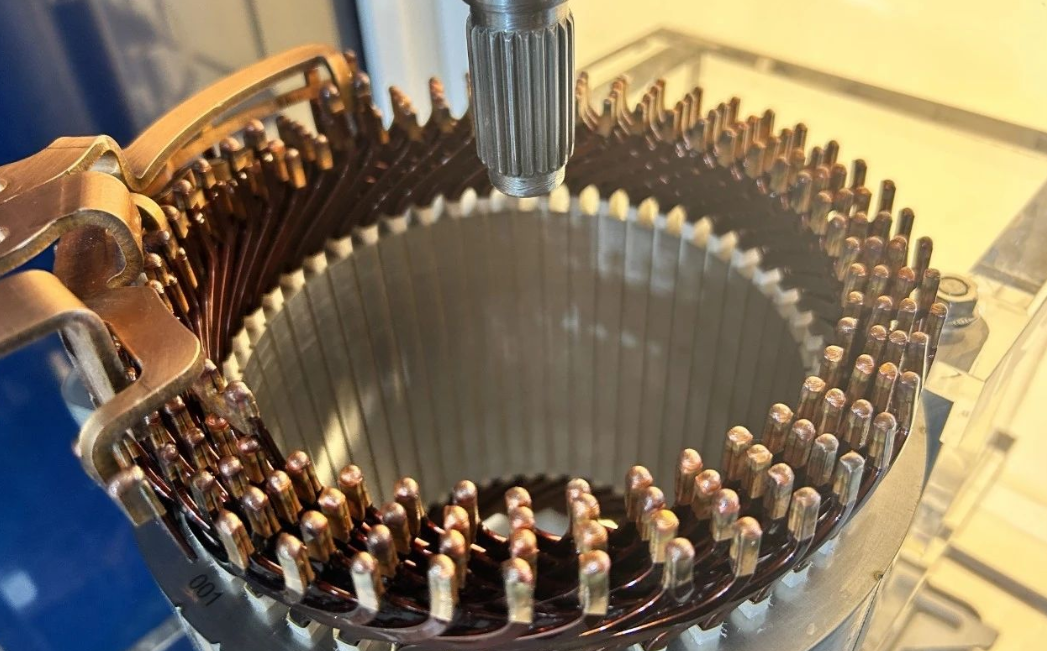

The key materials that affect the performance and cost of drive motors include permanent magnets, silicon steel sheets, copper wires, etc. In the future, it is necessary to focus on the development of high-strength, low-loss electrical steel and new soft magnetic materials, and high-temperature resistant low-heavy rare earth/weightless rare earth permanent magnets , high electrical conductivity, low loss super copper wire and corona resistant, high thermal conductivity insulation system, etc.

-

New soft magnetic materials include 6.5% Si high-silicon steel, amorphous/nanocrystalline alloys, soft magnetic composite materials, etc. The manufacturing process of 6.5% Si high-silicon steel is complex, resulting in difficult quality control, low production efficiency, and high cost; amorphous/nanocrystalline alloys have low saturation flux density, thin, brittle, hard materials, and difficult processing, and are more suitable for ultra-high speed, high power frequency motor.

-

NdFeB material is still the most important rare earth permanent magnet material, and the permanent magnet MQ3 material using Nd-Fe-B rapid quenching thermal deformation technology is one of the key focus of new permanent magnet materials. Reducing the amount of heavy rare earths is the current key research and development direction, and grain refinement technology, intergranular technology, intergranular diffusion technology, and comprehensive technology are the key points of research. In addition, the electric excitation motor does not need to use permanent magnets, which is also one of the industry's attention and potential product choices.

-

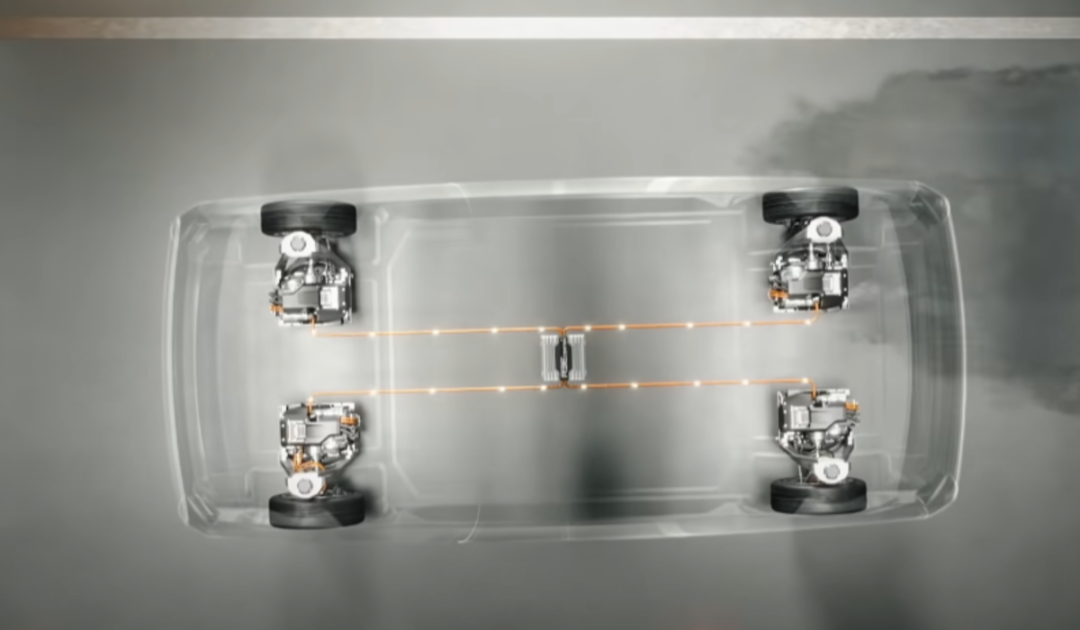

Distributed drive is an important choice for the development of electrification in the future, and it is mutually empowering with automatic driving. Distributed drive includes key technologies such as torque distribution and control, drive anti-slip control, fault-tolerant control and functional safety. At the same time, due to the challenges of distributed drive in terms of handling and cost, it may take the lead in high-end passenger cars and special vehicles ( High performance requirements and not cost sensitive) to realize the application.

-

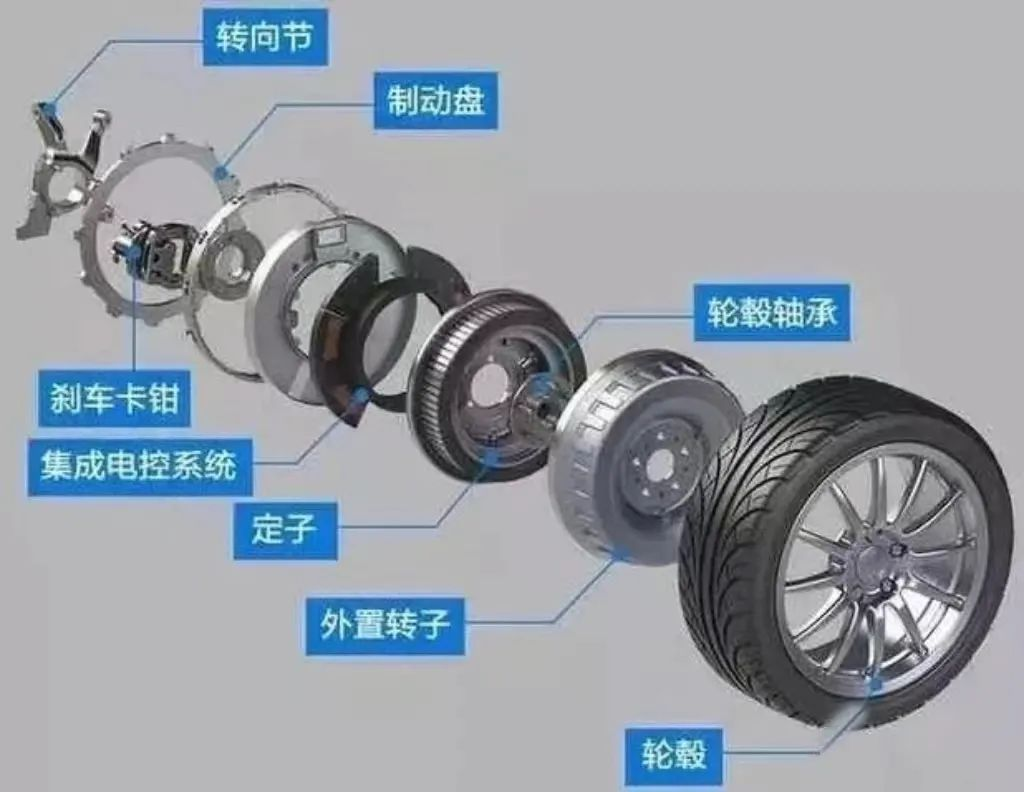

Wheel motors and hub motors are two important technical routes of distributed drives. The wheel side motor can give full play to the advantages of the electromechanical, thermal and magnetic multi-field design of the deeply integrated electric drive assembly, and realize the miniaturization and light weight of the drive motor and reducer assembly system. In-wheel motors are less difficult to engineer than in-wheel motors, but cost challenges remain.

-

In-wheel motors face multi-dimensional technical problems such as heat dissipation, sealing, control, and impact resistance. There is still a long way to go for mass production and application in the field of passenger vehicles. High-efficiency heat conduction and cooling technologies are required, and dustproof and waterproof Key breakthroughs are needed in engineering design and verification, such as low-resistance dynamic sealing technology and integrated corner module technology. Article Source: Technology Roadmap for Energy Saving and New Energy Vehicles

XINDA

XINDA