What is the difference between PMSM motor and AC asynchronous motor?

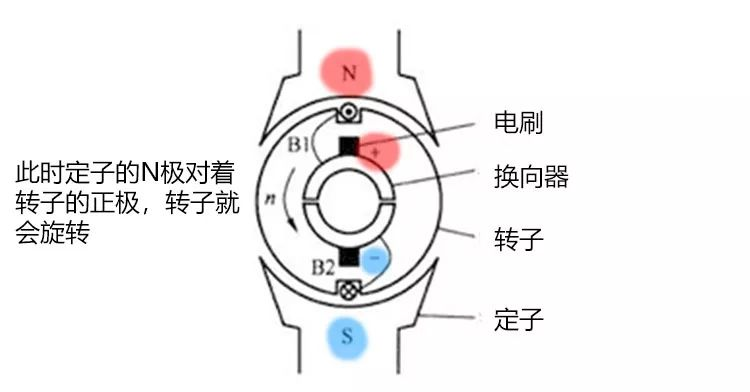

I believe everyone is familiar with the motor. Recall the physical DC brushed motor in high school. The principle has been the same for thousands of years. A permanent magnet (magnet) acts as a stator, and a coil acts as a rotor. According to the principle of "same sex repels, opposite sex attracts", he will rotate around the stator.

But, after turning 180 degrees, you will find that the N pole of the stator is next to the S pole of the rotor, and the two of them start to attract each other. What if it doesn't rotate? So at this time, you need to change the direction of the current through the rotor, but you cannot change the direction of the current of the power supply, so the commutator and brushes are needed at this time.

The main function of the brush is to conduct current, and its positive and negative poles are connected to the positive and negative poles of the battery. Every time the rotor rotates 180 degrees, the connection between the brush and the commutator changes, and the original positive pole of the coil becomes negative and negative. Become the positive pole, and alternately cycle in this way to realize the electromagnetic force to push the rotor coil to continue to rotate. However, because the brushes have been brushing on the commutator, it is bound to cause wear and tear, and if you are not lucky, sparks will occur.

As mentioned earlier, the brushes will wear out or even spark, so most cars now use brushless motors. The permanent magnet synchronous motors and AC asynchronous motors we are discussing this time are both brushless motors. Now let’s get to the point and give you Tell me the difference between the two:

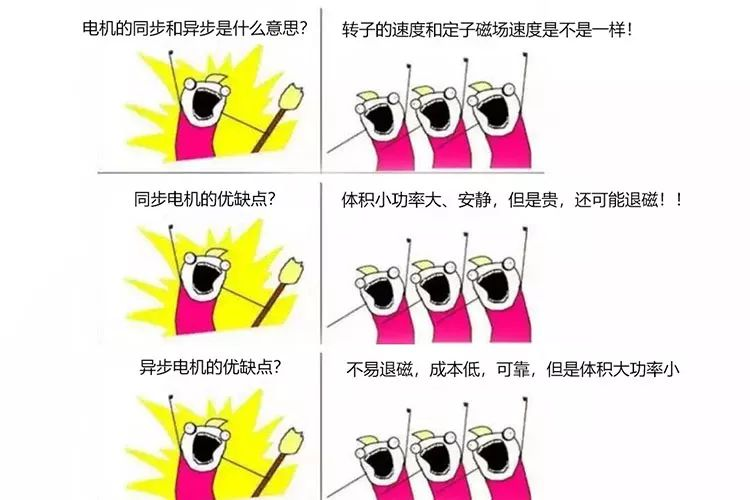

What do synchronous and asynchronous refer to?

It refers to whether the rotor speed is the same as the speed of the magnetic field generated by the stator. To fully understand the problem, we need to understand how both types of motors work.

Let's look at the permanent magnet synchronous motor first:

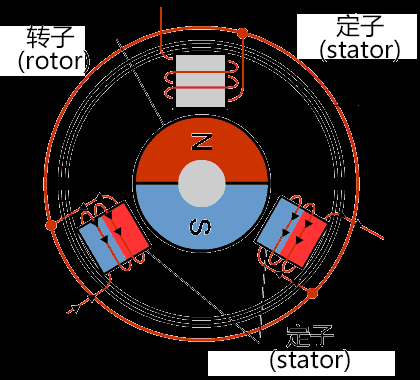

It should be noted that the permanent magnet synchronous motor is different from the motor in the textbook we used in the example above. Its coil is used as a stator, and the permanent magnet is used as a rotor, which is exactly the opposite of the textbook.

Let me talk about the permanent magnet first, most of which are now made of NdFeB material. This material is called "Permanent Magnet King", and it is the most magnetic permanent magnet material at present. Obtaining this material requires a rare item-rare earth.

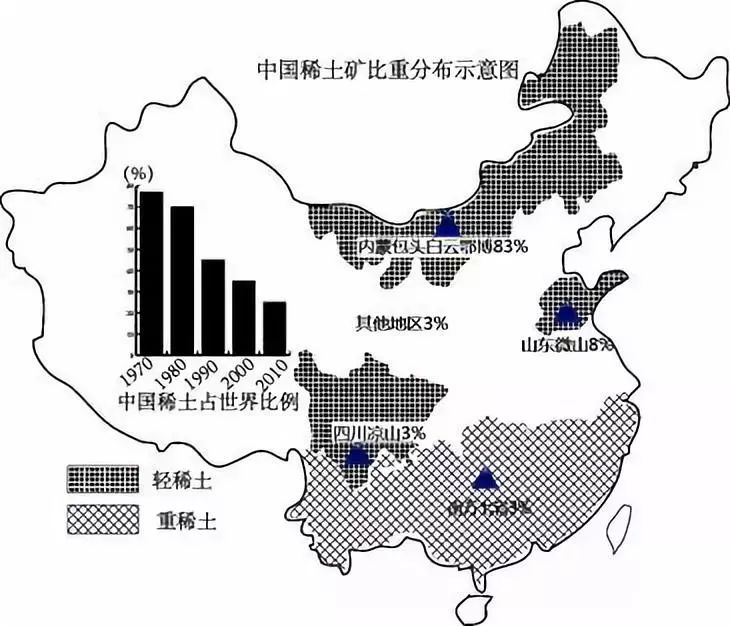

Here is a little popular science. The rare earth family is a collection of 15 elements from the lanthanide series, plus scandium and yttrium, a total of 17 elements that are closely related to the lanthanide series. China’s rare earth reserves accounted for 71.1% of the world at the time. Below 23%, China has also assumed the role of rare earth export in the past few years. Mr. Bang’s hometown is very good at dealing with rare earths, and even the university has set up a special rare earth college.

▲ NdFeB permanent magnet

The reason why there is so much nonsense here is to tell everyone that rare earths are very expensive and rare, so permanent magnets are very expensive, and permanent magnet DC motors are also very expensive.

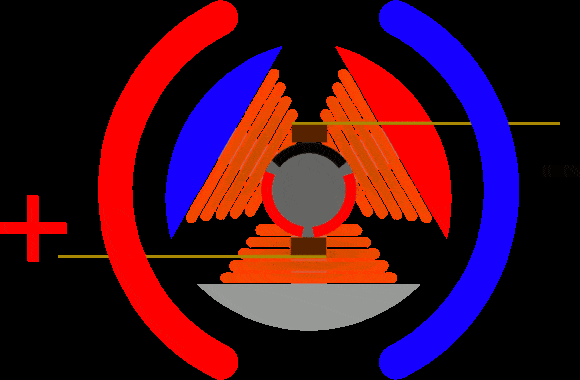

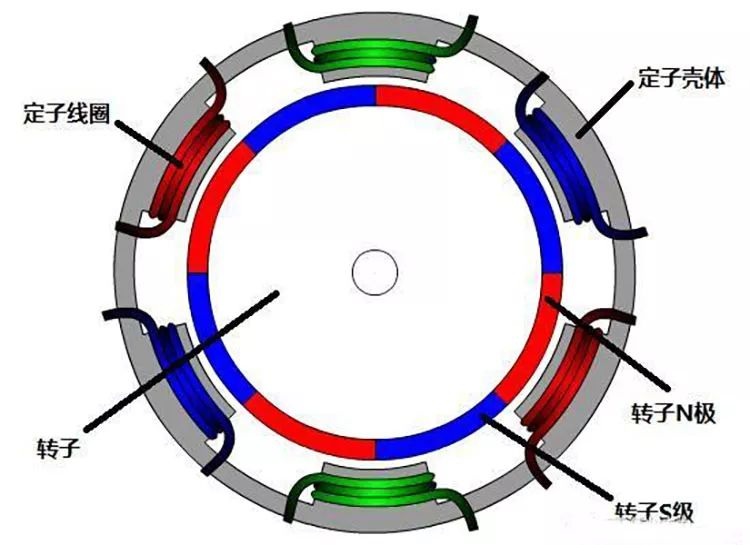

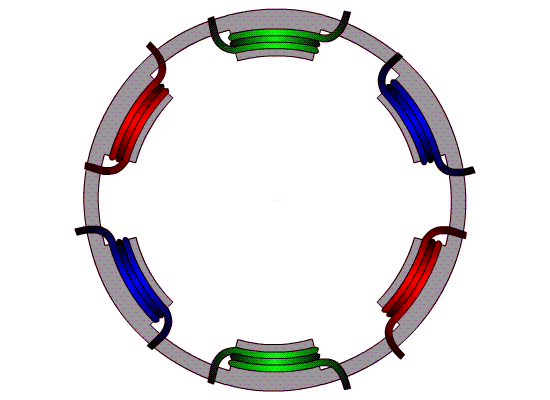

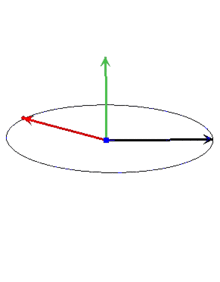

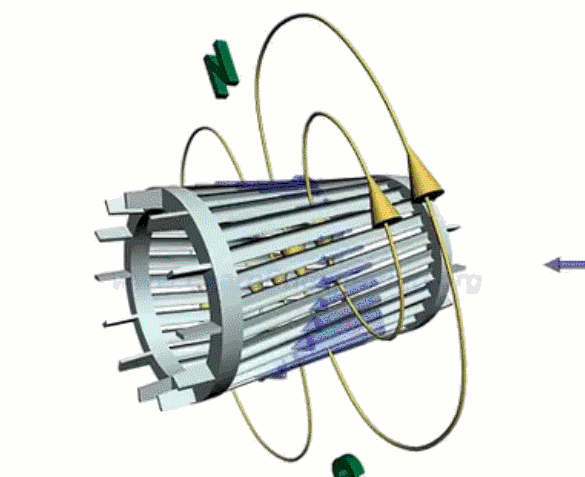

Okay, a little bit off topic, let's talk about permanent magnet synchronous motors. Because there are no brushes, the commutation must be done in an "electronic" way. The following is a schematic diagram of the structure of a permanent magnet synchronous motor:

The gray outer ring is the stator casing fixed on the vehicle body, on which three groups of six-turn coils of red, green and blue are wound at intervals, and the diagonal lines are the same group. The middle white wheel turns into a rotor, which connects the output shaft to the tire.

Suppose we energize the green coil first, then it will generate a magnetic field similar to a bar magnet. And if all three sets of coils are energized, the magnetic field of the three sets of coils is equivalent to three bar magnets placed inside the stator in a "meter" shape, and a continuously rotating magnetic field will be generated. At this time, the rotor will be subjected to the magnetic force generated by the stator. And turn.

Note that the bar magnet in the picture above is just to help you understand the magnetic field direction of the energized coil, not a magnet placed in the motor!

In this case, after the energized coil changes, the rotor can be stressed immediately, that is, the rotor speed is the same as the speed of the magnetic field generated by the stator, so it is called a synchronous motor.

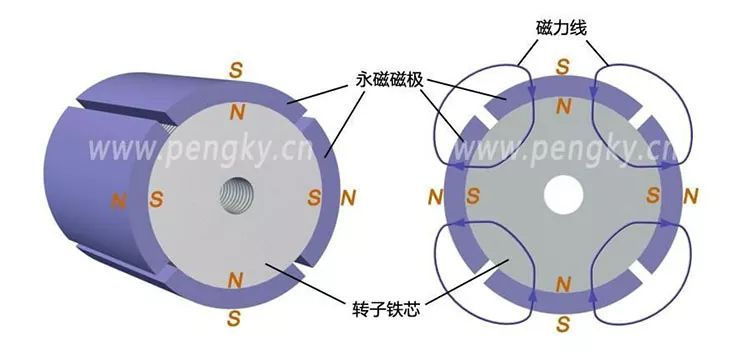

In addition, the rotor here is not a simple magnet. If so, the force will be uneven due to the single direction of the magnetic pole. Therefore, it generally puts more magnets on the stator to form a stator magnetic group, thus forming a SN pole spaced permanent magnet rotor.

In this way, the rotor in the magnetic field has a magnet force in any direction, so this makes the rotor rotate stably. Of course, the on-off of the coil is controlled by the rotor position sensor and the switch. The on-off of the three of them is not a simple "you turn on and off", but a more complicated on-off rule, which will not be detailed here.

Next we talk about AC asynchronous motors:

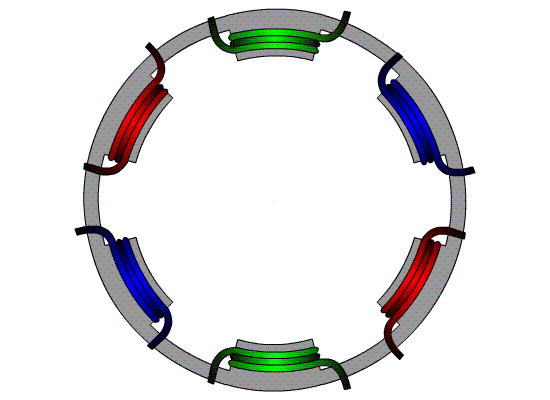

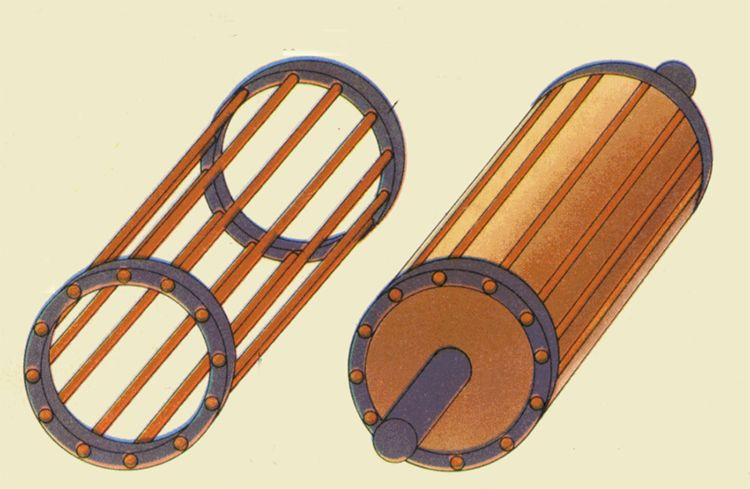

The stator of AC asynchronous motor is composed of iron core, winding and frame, and the rotor is composed of iron core and winding. The rotor winding has squirrel cage type and wire wound type. It looks like this:

It can be seen that the AC asynchronous motor has no permanent magnets, and its rotor and stator can only generate magnetic fields by electrification.

Since three-phase alternating current is used, every 120 degrees of the coil in the stator is a unit, a total of three units are arranged symmetrically with each other. Three individual windings are combined to form a 360-degree cylindrical stator.

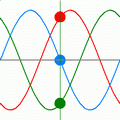

Because the frequency and direction of alternating current are constantly changing, if we pass alternating current to winding A, it will generate a magnetic field with constantly changing direction and size, and the same is true for the other two windings, similar to the following figure:

This picture only shows that the three windings will produce a magnetic field that changes in size and direction, and does not represent the real size and direction relationship!

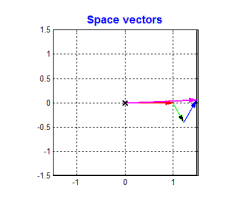

At this time, we need some knowledge of vector synthesis. The combination of these three magnetic fields with size and direction forms a magnetic field with changing size and direction. Then we adjust the order of energization: Phase A is energized first, and then phase B is energized after the AC voltage waveform of phase A swings for a third of the cycle, and phase C is energized after the voltage of phase B swings for another third of the cycle.

At this time, the synthesized magnetic field becomes like this: the size is fixed, and the direction changes regularly.

You can simply understand it like this~

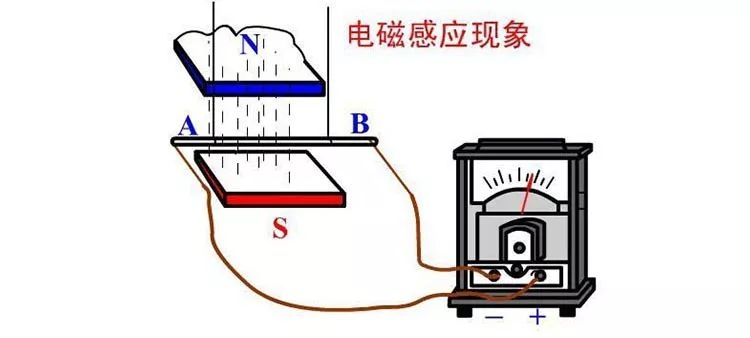

Alright, with this magnetic field, the rotor can finally rotate happily~ But since the rotor of the AC asynchronous motor is a squirrel-cage type, it will do the "conductor cutting magnetic induction line movement" familiar to us in junior high school physics in the magnetic field generated by the stator , an induced current is generated.

This current is acted by Ampere's force in the rotating magnetic field, causing the conductor to rotate. The superposition of these two rotations causes the speed of the rotor to be different from the speed of the magnetic field generated by the stator, which means "asynchronous". Specifically, you can see the following figure:

Advantages and disadvantages of synchronous/asynchronous motors?

Let’s talk about synchronous motor first. Its advantages are obvious. Under the same weight and volume, permanent magnet synchronous motor can output higher power and torque. In the same way, under the same power and torque conditions, its weight and volume are small, leaving enough space and quality for another extremely important component, the power battery. In addition, the permanent magnet synchronous motor also has the characteristics of low noise.

As for the disadvantages, as I said earlier, permanent magnets rely on rare earths. If you want high power, you need a large permanent magnet, which is expensive; demagnetization.

As for the asynchronous motor, the cost is very low, the process is simple, the operation is reliable, and the maintenance is convenient. It can work in a complex working environment and has a relatively strong adaptability to large changes in the surrounding working temperature.

However, under the same power and torque, the volume and weight required by the asynchronous motor are much larger than that of the permanent magnet synchronous motor.

Why does Tesla like to use asynchronous motors?

In fact, not only Tesla, but many European brands of electric vehicles like to use asynchronous motors, such as BMW i3, but Chinese and Japanese brands are not like this, and they still love permanent magnet synchronous motors deeply.

As for the reasons why foreign brands such as Tesla gave up the synchronous motors with obvious advantages, there are currently several inferences:

One is that asynchronous motors are better able to adapt to harsh environments, and Tesla, a model with a higher positioning, may experience more intense driving than family cars, so the characteristics of asynchronous motors that are not easy to demagnetize are very suitable for them.

The second is the issue of rare earths, the core material of permanent magnet synchronous motors. For my country and Japan, my country has good rare earth resources, and Japan is a big country in the rare earth industry. The world's top three NdFeB companies in sales: Sumitomo Special Metal Corporation, Xinyue Chemical Industry Co., Ltd. and TDK Group are all Japanese companies, and their strength is evident. European and American countries may not be able to use rare earth materials as they like.

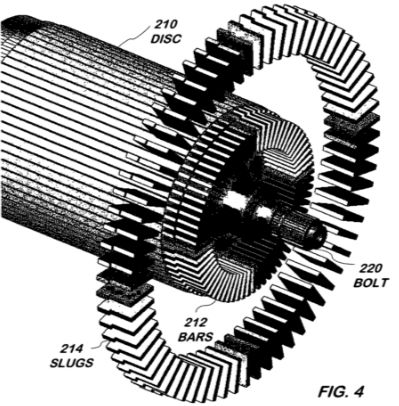

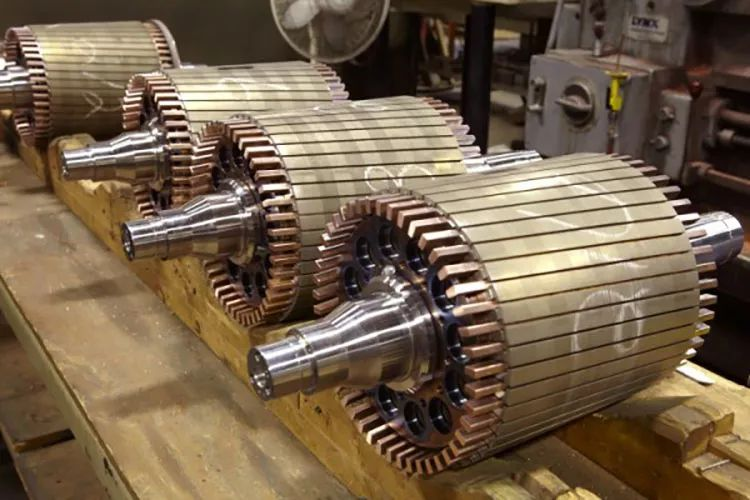

The third is that Tesla has its own patents on asynchronous motors, which avoid the shortcomings of asynchronous motors, such as the technology of copper core rotors. Let me briefly introduce them to you:

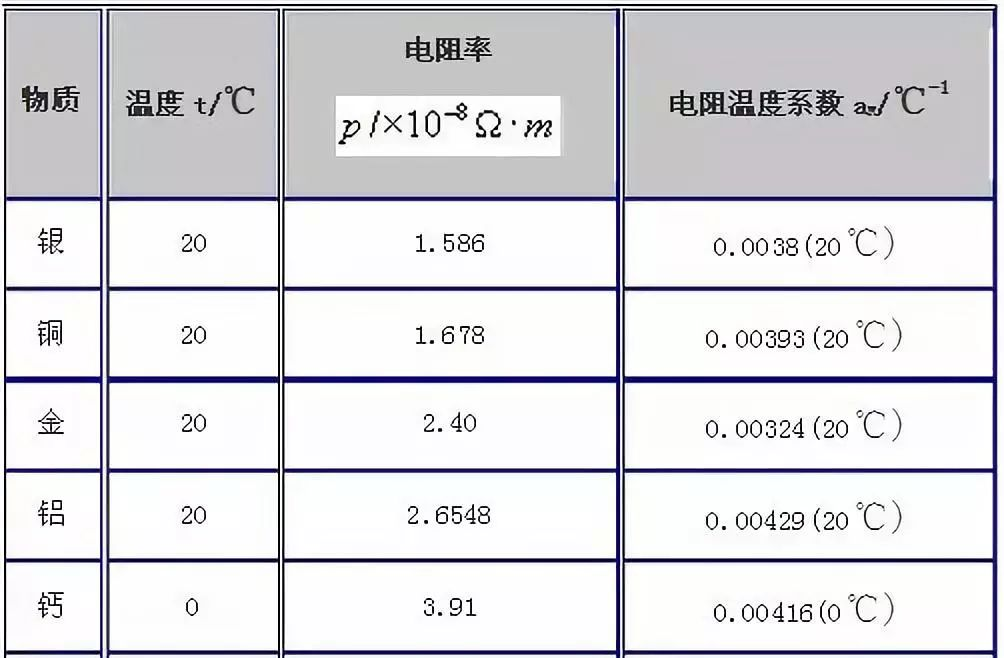

At present, the rotor of most asynchronous motors, that is, the squirrel cage, is made of aluminum. Aluminum has good electrical conductivity and low melting point (660.4°C). It also has advantages in cost, but its efficiency is limited, and it is difficult to go further. If you use Using copper with higher conductivity to make the squirrel cage, the efficiency of the motor will be significantly improved.

However, copper has a high melting point (1083°C), and copper core rotors are difficult to manufacture; and the cost of welding copper is also high, and the requirements for the strength of solder joints are also high.

▲ Different metal resistivity

Tesla's patented Rotor Design for An Electric Motor uses a welding copper process. First, it is the same as the welding squirrel cage technology. The copper strips are inserted into the rotor slots, and then the end rings should be welded, but Tesla has manufactured a set of surface Silver-plated copper wedges are inserted into the gaps at the ends of the copper strips. After the wedges are inserted, welding is performed between the wedges and the copper strips. This welding requires relatively low cost and difficulty. After the soldering is done, insert the end rings in again.

The real thing looks like this:

Ok, let's wrap up this article:

XINDA

XINDA