Under what circumstances does the motor need to be equipped with a reducer?

Date:2023-05-27 Author:Shandong Xinda Motor Co., Ltd.

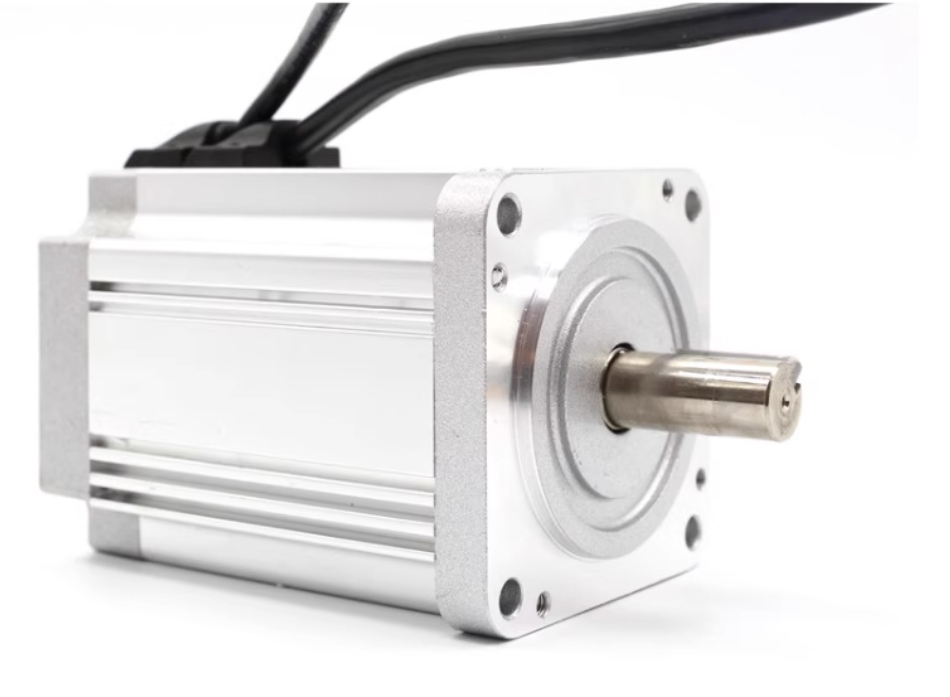

The motor is the most common power source for sports machinery. Today I will share under what circumstances the motor needs to be equipped with a reducer.

1. The reducer can achieve low speed and high torque.

In some occasions, the speed required is relatively small, but the torque is relatively large. If the motor speed is controlled to be very low, some motors are not the best to run at low speed, especially stepping motors. We can use a reducer to solve the problem. The function of the reducer is to reduce the speed and increase the output torque.

Speed Torque Curve of Stepper Motor

For example, the speed of a stepper motor is generally 300~600 revolutions per minute. In fact, the speed is only required to be less than 100 revolutions per minute, and the torque needs to be larger. If the stepper motor is directly connected, the speed is relatively low. The stepper motor The low-speed performance is not very good. In this case, you can add a reducer with a reduction ratio of 5, so that the motor runs at 500 rpm, and the output speed of the reducer is 100 rpm, which meets the requirements of low-speed operation. It also ensures sufficient torque output.

2. When the speed meets the requirements, it is more cost-effective to use a reducer.

Sometimes, when the motor speed meets the requirements but the torque requirements are large, method 1 can choose a motor with higher power. However, this method is not necessarily the most cost-effective, and the higher the power, the higher the price of the motor. The second method is to choose a reducer. If the reducer is selected, it can meet the requirements of the operating speed, increase the output torque, and save cost and space. The advantage of using a reducer is obvious.

3. The selection of the reducer has a certain effect on the motor.

Due to the addition of the reducer, the load directly acts on the reducer, and the force on the motor will be much smaller (1/reduction ratio), which protects the motor. Especially in the case of overload, the damage of the load to the motor is relatively large without a reducer.

In the case of overload, it may cause damage to the mechanism. If only the reducer is damaged, it is more cost-effective to replace the reducer. If the direct link between the motor and the load is overloaded, it is easy to damage the motor. The cost of replacing the motor is relatively high, and the cost of replacing the reducer will be relatively much lower.

When selecting a reducer, you can generally find the matching reducer model from the motor model, and then select the appropriate reducer according to relevant parameters such as speed, torque, reduction ratio, installation method, and installation size.

In addition, the reducer also has high precision and ordinary precision. The higher the precision of the reducer, the higher the price. Ordinary reducers may cost a few hundred yuan, while precision reducers cost thousands of yuan.So choose according to your needs.

XINDA

XINDA