How do industry giants quickly update electric drive solutions?

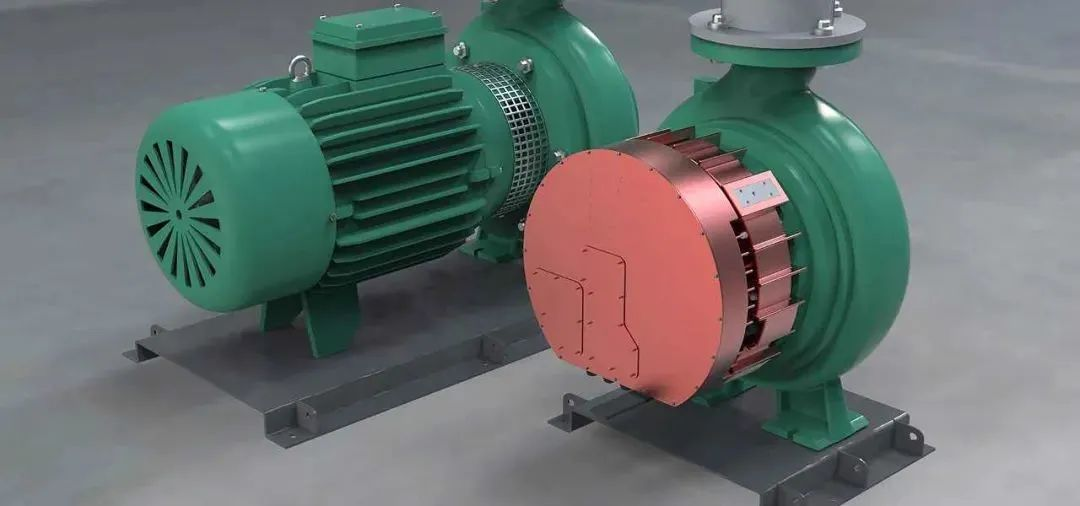

Infinitum chose to manufacture industrial motors that are huge in the market. Infinitum's solution (right) takes up less space than conventional wound motors. (Infinitum)

OEMs, suppliers, and start-ups are working to optimize existing technologies while breaking new ground. At the same time, the development of electric drivetrains is advancing at an impressive pace.

Current drive motors and electronics are already very efficient, but automakers are still innovating a lot to further improve the efficiency of electric vehicle powertrains. Here are some recent developments:

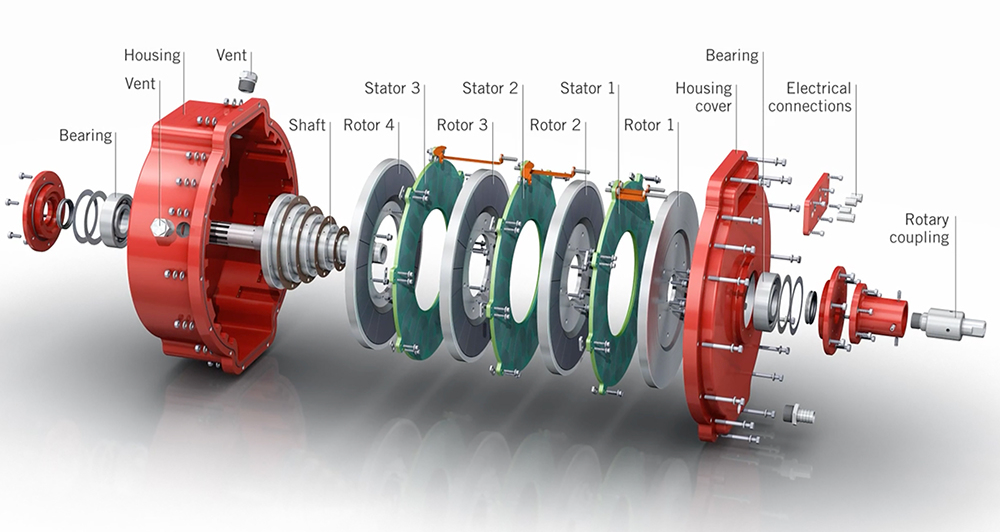

Infinitum removes all the iron and copper windings in the stator core of the motor from the stator and replaces them with a printed circuit board (PCB) stator with etched copper conductors, thereby introducing a motor that is smaller in size and lighter in weight than traditional axial flux motors. lighter motor. The design eliminates all core losses in the stator, such as torque ripple, cogging, stator hysteresis, and eddy currents, "dramatically improving efficiency." This motor is smaller, quieter and more efficient, with higher efficiency over the entire motor operating curve.

An exploded view of Infinitum's Aircore Mobility motor. (Infinitum)

Initially trying to address the inefficiencies of HVAC motors, Infinitum is currently focusing on the industrial market.

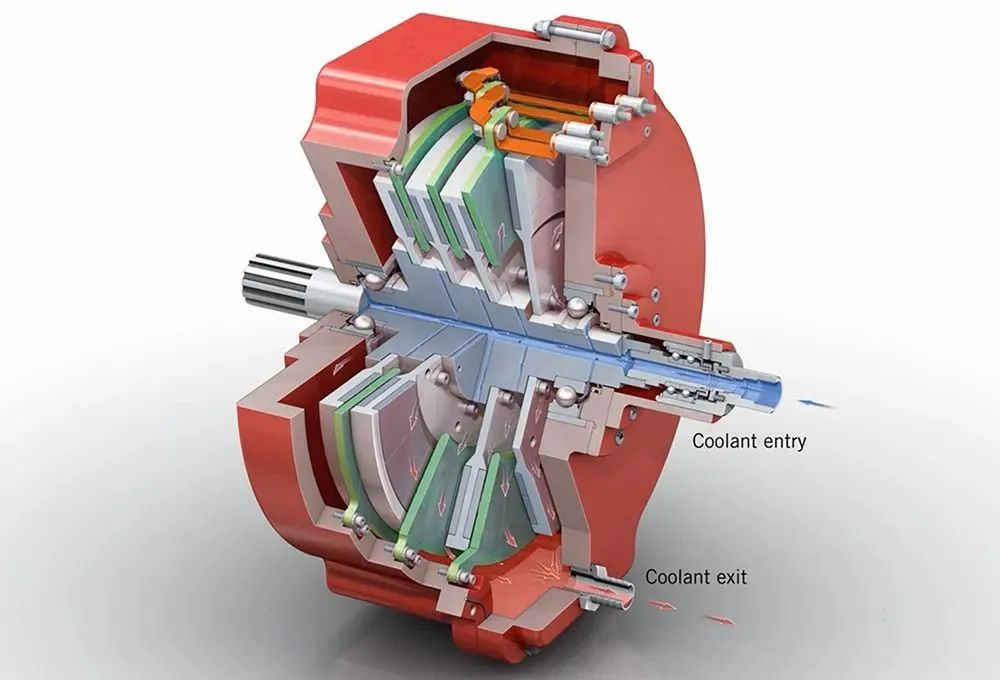

Infinium sends coolant directly to the center of the stator, where it spins outwards by centrifugal force, cooling the stator and other components until it hits the casing and drains into the sump, where it is recirculated. (Infinium)

At CES 2023, Infinitum announced its latest development - an air-core motor with a PCB stator, and its liquid cooling system can deliver coolant directly to the motor heat source. The motor injects coolant into the hollow shaft so that it is in direct contact with the stator, and the excellent heat dissipation makes the power density four to five times higher than that of traditional radial flux motors. Most of the cooling methods used in radial and axial flux motors can only inject coolant into the jacket around the motor. The Infinitum feeds coolant into the center of the stator, where centrifugal force pushes the liquid into the outer jacket, where it drains into a sump for recirculation, resulting in 150 kW (201 hp) continuous power and 300 kW (402 hp) peak power The motor can run at 95% efficiency at 7500 rpm.

Infinitum founder and CEO Ben Schuler. (Infinitum)

The person in charge of the company said that air-core motors using silicon carbide MOSFETs can achieve higher-speed switching. Motors can be updated OTA and can also be sized or replaced by multiple smaller motors based on the application.

Air core motors are designed for cycle use. The etched copper panel used off-the-shelf FR4 glass epoxy as insulation. This results in a 10-fold improvement in reliability over standard stators, the company says. How is this possible? Schuler's explanation: "All of our copper laminates and insulation materials have equal coefficients of thermal expansion and will do so at the same rate when repeatedly heated and cooled without mechanical interference and therefore will not fail."

Schaeffler is looking to improve the efficiency of permanent magnet motors by adjusting the position of the magnets, and is turning its attention to externally excited motors without magnets. Magnetless motors are generally less efficient, but Schaeffler engineers say it is possible to develop externally excited motors with "equal" efficiency to permanent magnet motors.

Schaeffler's 4in1 e-axle seeks to maximize systemization by integrating traction motors, transmissions, power electronics and thermal management systems (which can include heat pumps). (Schaeffler)

The company's recently revealed solution is the "4in1 e-axle" - which builds on the traction motor, transmission and power electronics in its 3-in-1 system, adding a thermal management system that greatly Improved efficiency. According to Schaeffler, the silicon carbide power electronics developed by various departments can provide more than 99% efficiency. Schaeffler's new four-in-one electric axle can integrate the shifting mechanism of the second-speed gearbox. Some This is considered a worthwhile addition for the larger vehicles with higher inertial weight favored by the US market. In addition, Schaeffler also supplies the corresponding decoupling unit.

In November 2022, ZF launched a new electric drive powertrain that combines many advantages. Like other designs focused on accommodating 400V or 800V architectures, its flexibility comes from the controller chip and inverter with individual power switches. The company claims that this architecture requires fewer components than today's power modules. The system has a minimum shaft power of 100 kW (134 hp) and a maximum of 300 kW. Related reading: ZF launches complete electric drive system to help OEMs shorten development time.

ZF's electric motors use braided windings to increase power density and reduce raw material usage. (ZF)

ZF's new electric drive system uses braided winding technology to increase power density. "The hairpin winding introduced five to seven years ago is state-of-the-art today, but requires hundreds of laser welding points," said Roland Hintringer, head of the motor product line. He also said that ZF's weaving was developed at the same time. Formed in one operation step, saving both time and space. It has a 15mm tip and a 28mm hairpin. Only 24 welding points are required, and the weaving method also saves 10% of raw material usage.

At the same time, ZF is also developing liquid cooling technology like Infinitum. In addition to the water-cooled motor housing, cooling oil is pumped around the housing and into the tanks of the braided windings themselves. Compared with the existing technology, the peak performance of this technology is increased by 85%, the power is increased by 50%, and the amount of rare earth is only 1% of the current level.

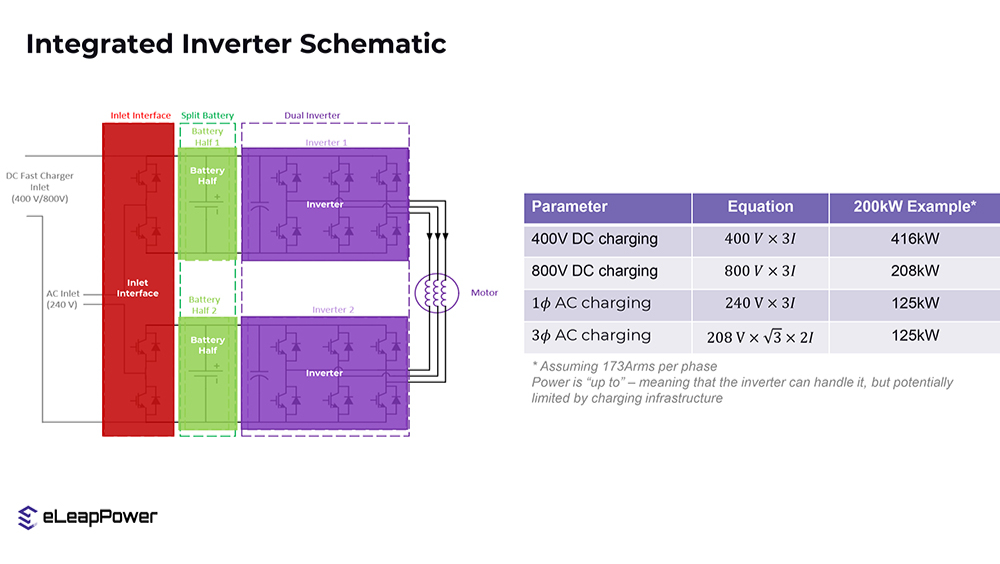

Canada-based eLeap Power says its inverter technology utilizes the motor windings already present in the drive motor, eliminating the need for an on-board charger and transformer. eLeap says the invention has a number of benefits:

-

800v charging speed, but compatible with 400v systems.

-

By eliminating the on-board charger, the weight of the vehicle is reduced by 30-40 kg (66-88 lbs), increasing the cruising range.

-

Compatible with almost all current electric vehicle powertrain architectures, and the cost is not high. Because it can accommodate 800v architectures while using the less expensive, lower voltage switching elements available today.

-

Fully bi-directional in AC and DC. This allows the vehicle battery to be directly charged using renewable resources such as wind and solar, while allowing the vehicle to "kinetic energy recuperate" during peak demand.

-

Inverters use split-battery or dual-battery systems for higher reliability. If part of the system fails, the vehicle will still be available.

eLeap Power's integrated inverter uses the motor's windings (the motor doesn't move) to replace the car charger and slow down charging. (eLeap Power)

The person in charge of eLeap believes that the system is more intelligent and more powerful. It reflects that the vehicle can be charged faster and can travel farther after charging. And save costs, and more environmentally friendly. At the heart of the eLeap system is that it uses the magnetic fields and windings in the motor, combined with software, to generate high-speed current to charge the battery. In addition to removing the car charger, vehicles such as the Lucid Air, which currently use a 400v/800v step-up converter, would also eliminate the need for a converter. "We also get a huge cost advantage because we use the motor in the charging operation. So, typically, you don't need an inductor and a transformer," he said. "The charging process is stationary, the motor doesn't rotate, there's no vibration .”

By splitting the battery, eLeap says it solves the problem other companies have had when they try to integrate the inverter, essentially putting the inverter in the middle of the process. (eLeap Power)

XINDA

XINDA