What bolts are used to fix the motor?

|

For the safety of amusement facilities, manufacturers usually use high-strength bolts to fix the motor. For commonly used motors, the number and size of the motor base have been determined before leaving the factory, and ordinary bolts can meet the design requirements. |

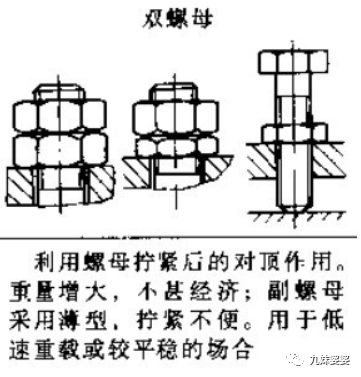

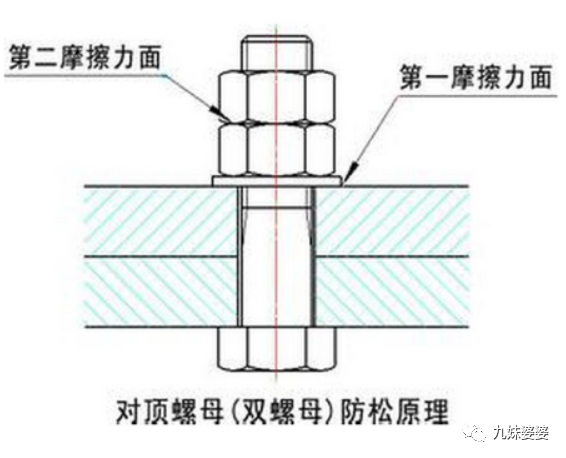

1. Anti-loosening method of bolts

2. Fixing method of motor and reducer

Ordinary bolt + flat washer + spring washer + nut

3. The function of spring washer and flat washer

The spring washer can prevent loosening and increase the pre-tightening force, while the flat washer does not have this function. It can be used to increase the fastening contact area, prevent the friction between the bolt and the workpiece, and protect the surface of the joint from bolts . Scratch the workpiece surface when the nut is tightened.

The spring washer is used to prevent loosening. The bolts connecting the motor and the machine base generally need spring washers, because if the motor vibrates without spring washers, the nuts will loosen. Generally, the fasteners on the equipment with vibration are equipped with spring washers.

However, some important connections, such as the place where the power is mainly transmitted by friction generated by compression, cannot use spring pads. If they are used to reduce the rigidity of the connection, it is easy to cause accidents. If the slewing bearing is installed, the spring washer is not used.

Four. Summary

When the strength of the connected parts is low, flat pads are used to increase the contact area. When there are vibrations, pulses, and relatively large fluctuations in the temperature of the medium, spring washers are used for shock absorption and anti-loosening.

XINDA

XINDA