Performance comparison of four electric vehicle motors!

As China's requirements for vehicle exhaust emissions become more and more stringent, the spring of new energy vehicles has arrived. Therefore, auto repair people are also hungry for knowledge of new energy vehicles. Today I will bring you the basic knowledge of new energy vehicle motors. I hope it will be helpful for you to understand new energy vehicles.

>>>>

1

What characteristics do motors on electric vehicles need to meet?

Based on the characteristics of electric vehicles, there are also high requirements for the motors used. In order to increase the maximum speed, the motor should have higher instantaneous power and power density (W/kg); in order to increase the driving distance of one charge, the motor should have higher efficiency; and electric vehicles work at variable speeds, so the motor should have High overall efficiency at high and low speeds; In addition, it has strong overload capacity, large starting torque, and fast torque response. When the electric vehicle starts and climbs, the speed is low, but the required torque is large; the torque required for normal operation is small, but the speed is high. It is a constant torque characteristic at low speed, and a constant power characteristic at high speed, and the operating speed range of the motor should be wide. In addition, the motor should also be strong, reliable, have certain dustproof and waterproof capabilities, and the cost should not be too high.

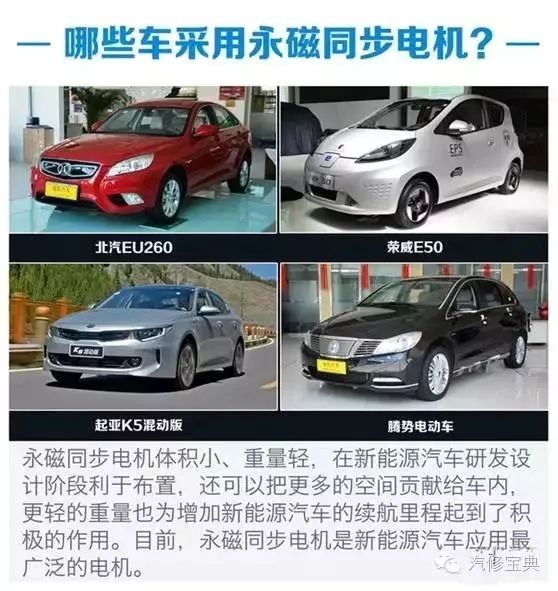

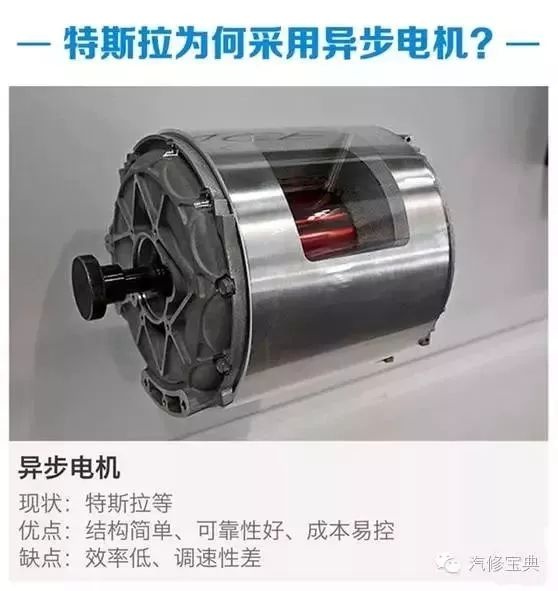

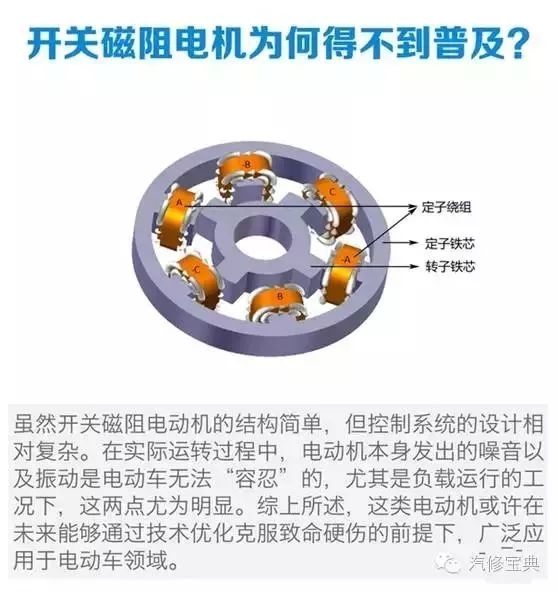

At present, judging from the mature motor technology, switched reluctance motors seem to be more suitable for the use of electric vehicles in terms of various technical characteristics, but they have not yet been popularized. Permanent magnet synchronous motors are widely used, such as Kia K5 hybrid, Roewe E50, Denza, Beiqi EU260, etc. Both Tesla Model X and Model S use asynchronous motors. In addition, if divided according to the type of current, it can be divided into two types: DC motor and AC motor. Through the table below, we can first have a general understanding of the characteristics of the four typical motors.

>>>>

2

In the early days of electric vehicle development, most electric vehicles used DC motors as drive motors. This type of motor technology is relatively mature, with the characteristics of easy control and excellent speed regulation. It used to be the most widely used in the field of speed-adjustable motors. However, due to the complex mechanical structure of the DC motor, its instantaneous overload capacity and further improvement of the motor speed are limited, and in the case of long-term work, the mechanical structure of the motor will generate losses and increase maintenance costs. In addition, when the motor is running, the sparks from the brushes will heat the rotor, which will cause high-frequency electromagnetic interference and affect the performance of other electrical appliances in the vehicle. Due to the above shortcomings of DC motors, the current electric vehicles have basically eliminated DC motors.

>>>>

3

In the field of new energy vehicles, permanent magnet synchronous motors are widely used. The so-called permanent magnet refers to the addition of permanent magnets when manufacturing the motor rotor to further improve the performance of the motor. The so-called synchronization means that the speed of the rotor is always consistent with the current frequency of the stator winding. Therefore, by controlling the frequency of the stator winding input current of the motor, the vehicle speed of the electric vehicle will be finally controlled. Compared with other types of motors, the biggest advantage of permanent magnet synchronous motors is that they have higher power density and torque density. To put it bluntly, compared with other types of motors, permanent magnet synchronous motors have the same mass and volume It can provide maximum power output and acceleration for new energy vehicles. This is also the main reason why permanent magnet synchronous motors are the first choice of the majority of automobile manufacturers in the new energy automobile industry that has extremely high requirements on space and self-weight. However, permanent magnet synchronous motors also have their own disadvantages. The permanent magnet material on the rotor will have magnetic degradation under high temperature, vibration and overcurrent conditions, so the motor is prone to damage under relatively complex working conditions. Moreover, the price of permanent magnet materials is relatively high, so the cost of the entire motor and its control system is relatively high.

>>>>

4

>>>>

5

Compared with permanent magnet synchronous motors, asynchronous motors have the advantages of low cost, simple process, reliable and durable operation, convenient maintenance, and can tolerate large operating temperature changes. Conversely, a large temperature change will damage the permanent magnet synchronous motor. Although the asynchronous motor is not dominant in terms of weight and volume, its speed range is wide and its peak speed is as high as 20,000rpm. Even if it does not match the secondary differential, it can meet the speed requirements of high-speed cruising for this class of vehicles. As for the impact of weight on battery life In terms of mileage, the 18650 battery with high energy density can "cover up" the disadvantage of motor weight. In addition, the excellent stability of the asynchronous motor is also an important reason why it was selected by Tesla.

>>>>

6

As a new type of motor, switched reluctance motor has the simplest structure compared with other types of drive motors. The stator and rotor are double-salient structure formed by laminating ordinary silicon steel sheets. There is no winding on the rotor, and the stator Equipped with a simple concentrated winding, it has many advantages such as simple and firm structure, high reliability, light weight, low cost, high efficiency, low temperature rise, and easy maintenance. Moreover, it has the excellent characteristics of good controllability of the DC speed control system, and is suitable for harsh environments. It is very suitable for use as a drive motor for electric vehicles. Experts have predicted that it will be a dark horse in the field of electric vehicles.

>>>>

7

The reason why an electric vehicle is called a new energy vehicle is because the energy used for its power is electricity, and the motor as its engine is the heart of an electric vehicle and is very important to an electric vehicle. In addition to the basic knowledge mentioned in this article, it is also necessary for auto repairers to know more about motors.

XINDA

XINDA