![]()

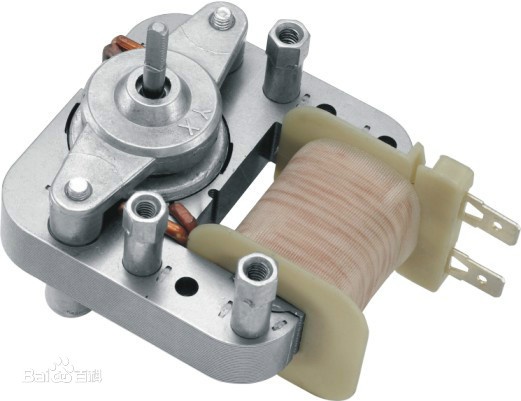

Shaded pole motor, also known as shaded pole motor (Shaded Pole Motor), is a type of single-phase AC motor, usually using a cage-shaped inclined slot cast aluminum rotor. According to the different shape and structure of the stator, it is divided into a salient pole shaded pole motor and a hidden pole shaded pole motor.

Structure

The shaded pole motor is mainly composed of a rotor assembly, a stator assembly, a wire package assembly, a bracket assembly and connecting fasteners. The rotor assembly is mainly composed of a cast aluminum rotor, shaft, thrust washer to prevent the rotor from moving back and forth, and a gasket to adjust the amount of movement; the stator assembly is mainly composed of a short-circuit ring and the main stator core; the wire package assembly is mainly composed of a coil, a skeleton, a lead Wiring or thermal protector and related insulating wrapping materials; bracket components are divided into front bracket components and rear bracket components according to the different installation positions of the shaft extension end and the non-shaft extension end.

Classification

Salient pole shaded pole

The shape of the stator core of the salient pole shaded pole motor is a square, rectangular or circular magnetic field frame. The concentrated winding on the salient pole serves as the main winding.

Shaded pole

The stator core of the hidden pole shaded pole motor is the same as that of the ordinary single-phase motor. The stator winding adopts distributed winding, and the main winding is distributed in the stator slot. The shaded pole winding does not need short-circuit copper rings, but is wound with thicker enameled wire. Distributed windings (self-short-circuited after being connected in series) are embedded in the stator slots (about 1/3 of the total number of slots) and act as auxiliary groups. The main winding and the shaded pole winding are separated by a certain angle in space.

When the main winding of the shaded pole motor is energized, the shaded pole winding will also generate induced current, so that the magnetic flux of the stator magnetic pole covered by the shaded pole winding and the unshielded part will rotate in the direction of the covered part.

The advantage of the shaded pole motor is that it has a simple structure and does not need additional windings and capacitors. The disadvantages are low efficiency and large slip.

The drainage pump used in the air conditioner embedded machine is a typical shaded pole motor with a low defect rate, and the general fault is that the motor is dirty and blocked.

Features

1. Reasonable structural design, flexible lead wire direction, and the terminal box of the shaded pole motor can be rotatably installed

2. Superior shaded pole motor performance, low noise, low vibration, high performance protection level

3. Many choices to meet various user needs to install thermistor

4. The optimized design is adopted, which has high efficiency and can produce considerable energy-saving effects

5. Install dust-proof sealing ring, heating belt , oil-proof sealing ring, oil injection, special shaft extension, special flange and other requirements.

Fault type

1. Insulating skeleton or insulating material

The frame is generally injection-molded, and the quality of the mold, the control of the injection molding process, and the cleanliness of the plastic particles will all cause its defects. The defects of skeleton or insulating material are as follows:

(1) The skeleton is short of material;

(2) damaged;

(3) worn out by the short-circuit ring;

(4) The skeleton contains impurities;

(5) There are dirt such as oil stains on the surface of the skeleton;

(6) The insulation sheet is pierced.

2. Hanging wire during winding process

When winding the wire, on the one hand, because the stator and the frame do not fit together, on the other hand, the winding needle of the winding machine may not be adjusted to be completely in the middle and upper part of the frame, and there is a certain arc when winding the needle and the wire, which may cause the enameled wire to not conform to the design. When the track is embedded in the wire package, there will be hanging wires, that is, the enameled wire is not wound on the plastic skeleton, and there will be one or several turns on the inner or outer groove wall of the skeleton groove or slip from the gap between the skeleton and the silicon steel sheet stator. It is directly wound on the stator, this kind of fault occurs most frequently, and other bad phenomena include:

(1) The first coil hanging at the beginning of winding;

(2) There are burrs on the skeleton, which will jam the wire and cannot be embedded;

(3) During the production process of employees, waste wires fall into the wire bag;

(4) The wire package is one-sided or full.

Third, the hanging wire caused by the wiring process

(1) The connectors between the wire packages are not sorted and stuffed into the skeleton after welding, and the wire ends are too close to the stator and the end cover;

(2) The last circle of enameled wire is loose and falls out of the skeleton, but it is not found, so it is directly tightened from the outside of the skeleton and comes from the stator;

(3) Floating line at the lead-out line;

(4) The thermal protector extrudes the wire. The general structure is to wrap the enameled wire on the copper core wire head of the thermal protector lead wire and use a sleeve sleeve for insulation protection, but if it is misplaced, it will cause breakdown.

XINDA

XINDA