Comprehensive motor knowledge interpretation, from motor classification to model selection

Motor type, soft start method, selection steps, damage causes and treatment methods, the difference between good and bad motors... All these problems are important reflections of the motor happiness index.

Let's take a look

Basic knowledge of motors 01

Differences between various types of motors 1

Difference between DC and AC motors

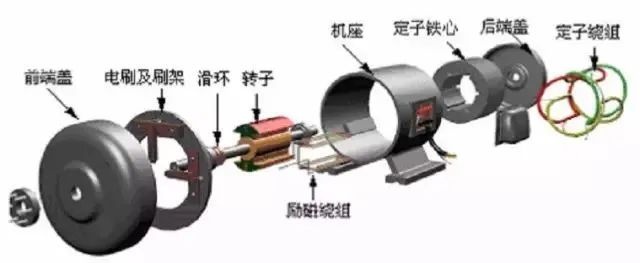

Structural diagram of DC motors

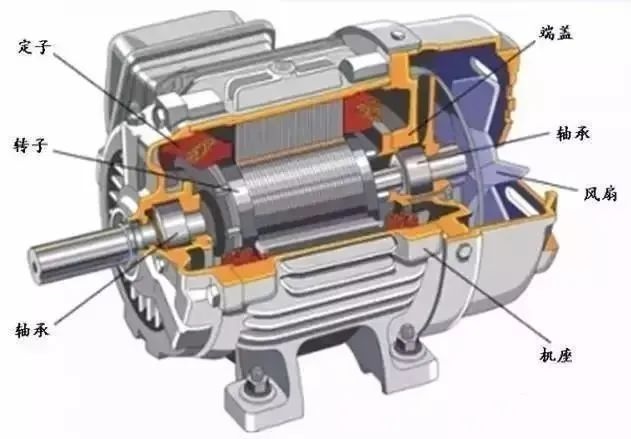

Schematic diagram of AC motor structure

As the name implies , DC motors use DC as their power source, while AC motors use AC as their power source .

Structurally speaking, the principle of DC motors is relatively simple, but the structure is complex and not easy to maintain. The principle of the AC motor is complicated but the structure is relatively simple, and it is easier to maintain than the DC motor.

In terms of price , DC motors with the same power are higher than AC motors. Including the speed control device that controls the speed, the price of DC is higher than that of AC. Of course, the structure and maintenance are also very different.

In terms of performance , due to the stable speed and precise speed control of DC motors, which cannot be achieved by AC motors, DC motors have to be used instead of AC motors under the strict requirements of speed.

AC motor speed regulation is relatively complicated, but it is widely used because chemical plants use AC power.

2

Differences between synchronous and asynchronous motors

The rotor rotates at the same speed as the stator, which is called a synchronous motor . If not, it is called an asynchronous motor .

3

The difference between ordinary and variable frequency motors

First of all, it is clear that ordinary motors cannot be used as variable frequency motors. Ordinary motors are designed according to constant frequency and constant voltage, and it is impossible to fully meet the requirements of frequency converter speed regulation, so they cannot be used as variable frequency motors.

The impact of the frequency converter on the motor is mainly in the efficiency and temperature rise of the motor.

The frequency converter can generate different levels of harmonic voltage and current during operation, so that the motor operates under non-sinusoidal voltage and current, and the high-order harmonics inside will cause the motor to Stator copper loss, rotor copper loss, iron loss and additional loss increase.

The most notable one is the copper loss of the rotor. These losses will cause the motor to generate extra heat, reduce the efficiency, and reduce the output power. The temperature rise of ordinary motors generally increases by 10%-20%.

The carrier frequency of the frequency converter ranges from a few kilohertz to more than ten kilohertz, so that the stator winding of the motor has to withstand a high voltage rise rate, which is equivalent to applying a steep impulse voltage to the motor, which makes the inter-turn insulation of the motor suffer more serious damage. test.

When an ordinary motor is powered by a frequency converter, the vibration and noise caused by electromagnetic, mechanical, ventilation and other factors will become more complicated.

The harmonics contained in the variable frequency power supply and the inherent space harmonics of the electromagnetic part of the motor interfere with each other to form various electromagnetic excitation forces, thereby increasing the noise.

Due to the wide operating frequency range of the motor and the wide range of rotational speed, it is difficult for the frequency of various electromagnetic force waves to avoid the natural vibration frequency of each structural part of the motor.

When the frequency of the power supply is low, the loss caused by the high-order harmonics in the power supply is relatively large; secondly, when the speed of the flexible motor decreases, the cooling air volume decreases proportionally to the cube of the speed, so that the heat of the motor cannot be dissipated, and the temperature rises sharply increase, it is difficult to achieve constant torque output.

How to distinguish between ordinary motors and variable frequency motors? Differences in the structure of ordinary motors and variable frequency motors

01. Higher insulation level requirements

The insulation level of general variable frequency motors is F or higher, and the ground insulation and the insulation strength of the turns are strengthened. In particular, the ability of the insulation to withstand shock voltage should be considered.

02. Higher vibration and noise requirements for variable frequency motors

Frequency conversion motors should fully consider the rigidity of the motor components and the whole, and try to increase its natural frequency to avoid resonance with each force wave.

03. Different cooling methods for frequency conversion motors Frequency

conversion motors are generally cooled by forced ventilation, that is, the cooling fan of the main motor is driven by an independent motor.

04. Different protection measures require

bearing insulation measures for frequency conversion motors with a capacity exceeding 160KW. The main reason is that it is easy to produce magnetic circuit asymmetry and axial current. When the currents generated by other high-frequency components work together, the axial current will increase greatly, resulting in bearing damage, so insulation measures are generally taken. For constant power variable frequency motors, when the speed exceeds 3000/min, special grease with high temperature resistance should be used to compensate for the temperature rise of the bearing.

05. The heat dissipation system is different.

The frequency conversion motor cooling fan is powered by an independent power supply to ensure continuous heat dissipation.

Motor Basics 02

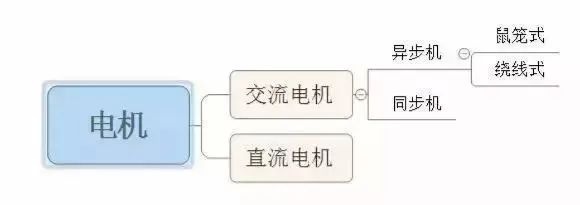

Motor type

selection The basic contents required for motor type selection include:

the type of load to be driven, rated power, rated voltage, rated speed, and other conditions.

Load type · DC motor · Asynchronous motor · Synchronous motor

The load is stable, and there is no special requirement for starting and braking for continuous operation of production machinery. Ordinary squirrel-cage asynchronous motors should be preferred, which are widely used in machinery, water pumps, fans, etc.

Starting and braking are relatively frequent, and production machinery that requires a large starting and braking torque, such as bridge cranes, mine hoists, air compressors, irreversible rolling mills, etc., should use wound asynchronous motors.

Where there is no requirement for speed regulation, where constant speed is required or power factor improvement is required, synchronous motors should be used, such as medium and large capacity water pumps, air compressors, elevators, mills, etc.

The speed regulation range is required to be above 1:3, and the production machinery that requires continuous, stable and smooth speed regulation should use separately excited DC motors or squirrel-cage asynchronous motors or synchronous motors with frequency conversion speed regulation, such as large precision machine tools, gantry planers, Rolling mills, elevators, etc.

For production machinery that requires large starting torque and soft mechanical characteristics, use series-excited or compound-excited DC motors, such as trams, electric locomotives, and heavy cranes.

Generally speaking , the motor can be roughly determined by providing the type of load driven, the rated power, rated voltage, and rated speed of the motor.

But these basic parameters are not enough if the load requirements are to be met optimally.

The parameters that need to be provided include: frequency, working system, overload requirements, insulation level, protection level, moment of inertia, load resistance moment curve, installation method, ambient temperature, altitude, outdoor requirements, etc. (provided according to specific conditions)

Motor Basics 03

Motor Troubleshooting Methods When

the motor is running or fails, four methods can be used to prevent and eliminate the fault in time, so as to ensure the safe operation of the motor . 1. Check and observe whether there is any abnormality during the operation of the motor, which is mainly manifested in the following situations.

1. When the stator winding is short-circuited, you may see smoke from the motor. 2. When the motor is seriously overloaded or running without phase, the speed will slow down and there will be a heavy "humming" sound. 3. The motor maintenance network is running normally, but when it stops suddenly, you will see sparks from the loose wiring; the fuse is blown or a part is stuck. 4. If the motor vibrates violently, it may be that the transmission device is stuck, the motor is not fixed properly, or the anchor bolts are loose. 5. If there are discoloration, burn marks and smoke traces at the contact points and connections in the motor, it may indicate local overheating, poor contact at conductor connections, or burnt windings.

2. When listening to the normal operation of the motor, it should emit a uniform and light "hum" sound, without noise or special sound.

If there is too much noise, including electromagnetic noise, bearing noise, ventilation noise, mechanical friction sound, etc., it may be a precursor or phenomenon of failure.

1. For electromagnetic noise, if the motor makes a high and low and heavy sound, there may be the following reasons: (1) The air gap between the stator and the rotor is uneven. At this time, the sound is high and low and the interval between high and low No change, this is due to the wear of the bearings so that the stator and rotor are not concentric. (2) The three-phase current is unbalanced. This is due to misgrounding, short circuit or poor contact of the three-phase windings. If the sound is dull, it means that the motor is seriously overloaded or running with a lack of phase. (3) The iron core is loose. During the operation of the motor, the fixing bolts of the iron core are loosened due to vibration, resulting in the loosening of the silicon steel sheet of the iron core and making noise.

2. For bearing noise, it should be monitored frequently during the operation of the motor. The monitoring method is: put one end of the screwdriver against the bearing installation part, and the other end close to the ear, and you can hear the sound of the bearing running. If the bearing is in normal operation, the sound will be a continuous and small "rustling" sound, without fluctuating highs and lows and metal friction sounds.

If there are the following sounds, it is abnormal:

(1) There is a "squeak" sound when the bearing is running. This is the metal friction sound, which is usually caused by the lack of oil in the bearing. The bearing should be disassembled and filled with proper amount of grease. (2) If there is a "chirp" sound, this is the sound made when the ball rotates. Generally, it is caused by dry grease or lack of oil, and an appropriate amount of grease can be added. (3) If there is a "click" or "creak" sound, it is the sound produced by the irregular movement of the balls in the bearing. This is caused by the damage of the balls in the bearing or the long-term use of the motor and the dryness of the grease.

3. If the transmission mechanism and the driven mechanism make continuous sound instead of fluctuating high and low, it can be dealt with in the following situations. (1) The periodic "crack" sound is caused by the unevenness of the belt joint. (2) The periodic "booming" sound is caused by the looseness between the coupling or the pulley and the shaft and the wear of the key or keyway. (3) The uneven collision sound is caused by the blades colliding with the fan cover.

3. Smell The fault can also be judged and prevented by smelling the smell of the motor.

Open the junction box and smell it with your nose

to see if there is a burnt smell. If you find a special smell of paint, it means that the internal temperature of the motor is too high; Wear or winding has been burned.

If there is no smell, it is necessary to use a megohmmeter to measure that the insulation resistance between the winding and the casing is lower than 0.5 megabytes, and it must be dried. If the resistance is zero, it means it is damaged.

4. Touching the temperature of some parts of the motor can also determine the cause of the fault.

In order to ensure safety, the back of the hand should be used to touch the motor casing and the parts around the bearing when touching by hand.

If abnormal temperature is found, the reasons may be as follows: 1. Poor ventilation. For example, the fan falls off, the ventilation channel is blocked, etc. 2. Overload. As a result, the current is too large and the stator windings are overheated. 3. Turn-to-turn short circuit of the stator winding or unbalanced three-phase current. 4. Frequent starting or braking. 5. If the temperature around the bearing is too high, it may be caused by bearing damage or lack of oil.

Motor bearing temperature regulations, abnormal causes and treatment

The regulations stipulate that the maximum temperature of rolling bearings does not exceed 95°C, and the maximum temperature of sliding bearings does not exceed 80°C. And the temperature rise shall not exceed 55°C (the temperature rise is the bearing temperature minus the ambient temperature during the test).

Reasons and solutions for excessive bearing temperature rise:

(1) Reason: The shaft is bent and the center line is not accurate. Treatment: Find the center again.

(2) Reason: The foundation screws are loose. Treatment: Tighten the foundation screws. (3) Reason: The lubricating oil is not clean. Treatment: replace the lubricating oil.

(4) Reason: The lubricating oil has been used for too long and has not been replaced. Treatment: Clean the bearings and replace the lubricating oil.

(5) Reason: The ball or roller in the bearing is damaged. Treatment: replace the new bearing.

Solution: 1. Open the module cover, and replace the damaged fuse, charging resistor and other components in the module. 2. Replace the damaged optical sub-board or protection diode. 3. The optical fiber is connected normally according to the label. If the optical fiber is damaged, replace it. 4. Replace the module power board.

XINDA

XINDA