The new energy drive motor market has huge room for growth in 2025!

In 2021, the production and sales of new energy vehicles in China will exceed 3.5 million, a year-on-year increase of 1.6 times, ranking first in the world for seven consecutive years, and the cumulative promotion volume has exceeded 9 million. New energy vehicles play a pivotal role in the strategic choice for the high-quality development of China's auto industry and China's important measures to achieve the "double carbon" goal. With the advantages of high power density, high operating efficiency, simple and compact structure, large and smooth torque, and good speed regulation performance, permanent magnet synchronous motors have occupied an absolute mainstream position in the domestic new energy vehicle drive motor market. According to GGII data, the installed capacity of permanent magnet synchronous motors will account for as high as 94% in 2021; in 2021, the top five domestic drive motor installed companies are BYD/Tesla/Founder Motor/Ningbo Shuanglin/ For Weiran Power, the installed volume is 62/40/25/20/180,000 units, accounting for 18%/12%/7%/6%/5%. Benefiting from the rapid growth of new energy passenger vehicles, the improvement of motor performance and the increase in the proportion of dual-motor configuration models, the analysts of the agency predict that the market space for new energy passenger vehicle drive motors is expected to reach 38.5 billion yuan in 2025.

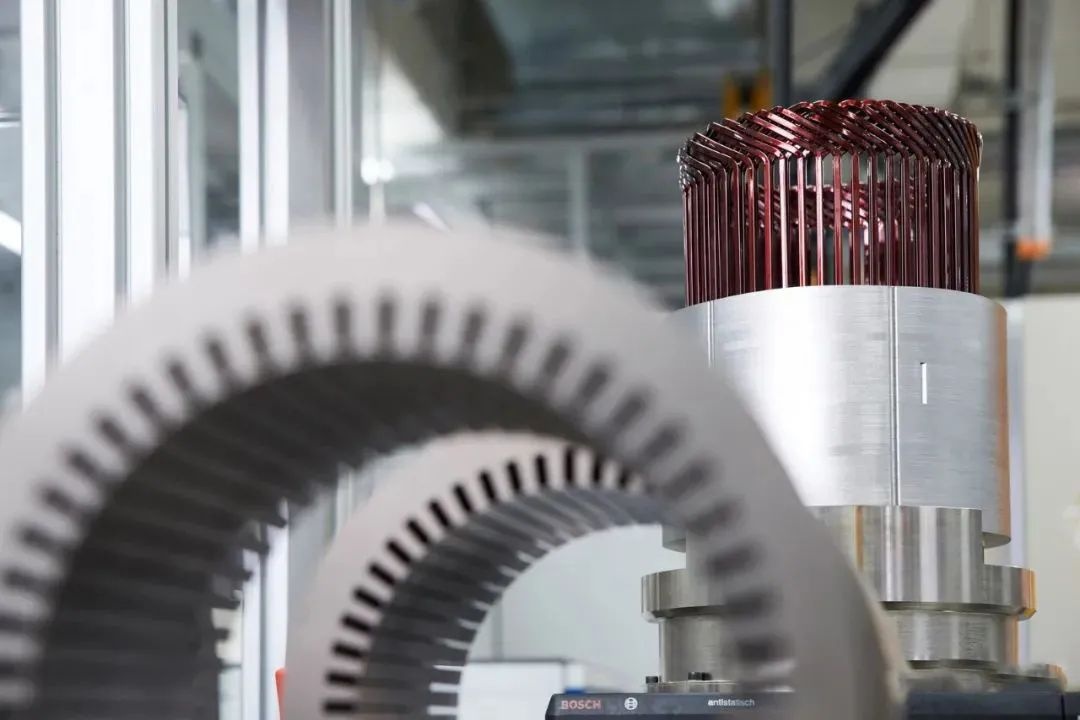

Development trend: flat wire, oil cooling, all-in-one

Compared with the traditional round wire motor, the flat wire motor can increase the full rate of the bare copper slot by 20%-30%, the total copper consumption has decreased by 21%, and the efficiency has increased by about 1%;

Under the oil cooling technology, the cooling oil can directly contact the heating parts of the motor, and the heat dissipation efficiency is much higher than that of the traditional water cooling system, and the oil medium has the advantages of good insulation, high dielectric constant, low freezing point and high boiling point. The drive motor of BYD DMI adopts direct injection rotor oil cooling technology, which can increase the power density of the motor by 32%

The all-in-one electric drive system integrates components such as motors, reducers, and controllers, and shares parts such as housing wiring harnesses to achieve integration, cost reduction, and light weight. The gap between the flat copper wires of the flat wire motor is large, and the cooling oil is easy to penetrate, which promotes the application of direct oil cooling technology. At the same time, the cooling oil has good insulation and can be reused in multiple scenarios, which accelerates the integration process of the vehicle's thermal management system and promotes the popularization of the all-in-one electric drive system assembly.

Benchmarking companies: Tesla and BYD continue to innovate, and third-party motor manufacturers make rapid progress

Tesla uses a built-in permanent magnet synchronous reluctance motor to alleviate the limitations of permanent magnet motors under high speed conditions, adds a carbon fiber protective layer to the motor rotor with excellent production technology, and develops a 10-layer flat wire winding motor.

BYD adopted the technical solution of front-drive induction asynchronous motor + rear-drive permanent magnet synchronous motor on the E platform 3.0, and landed the world's first eight-in-one powertrain. BYD's EHS electric hybrid system on the plug-in hybrid system adopts an integrated design of dual motors + dual electric controls. The power density of the flat-line oil-cooled motor has increased to 44.3KW/L, and the volume and weight have been reduced by 30%.

In addition, BYD drives the permanent magnet to rotate through the ring gear structure, which alleviates the problem of field weakening control of the permanent magnet synchronous motor.

High-quality third-party motor manufacturers such as Jingjin Electric, Inovance Technology, Juyi Technology, Founder Motor, and Dayang Motor have developed and mass-produced their own electric drive products.

Recommended target: a high-quality third-party electric drive system supplier

Jingjin electric: experts run the enterprise, independent research and development, enter the supply chain of Xiaopeng. Founder Motor: Customer development is smooth, and the growth of the motor leader is accelerating. Juyi Technology: Intelligent equipment and electric drive system go hand in hand. Dayang Motor: a comprehensive layout, a high-quality supplier of global motor and drive control systems.

XINDA

XINDA