Motor, battery, electronic control! Who is the most important "three power" technology?

The "three power" technology of new energy electric vehicles, I believe many friends can say "battery, motor, electronic control", not only consumers put "battery" in the first place, manufacturers also often put "battery" in publicity. "Battery technology" is used to demonstrate, so why do consumers and manufacturers first mention battery technology instead of motor technology? We explain this problem from two aspects.

The battery life and safety of electric vehicles are the concerns of consumers and manufacturers

Compared with fuel vehicles, electric vehicles are currently affected by the overall infrastructure layout. Consumers are most concerned about battery life, and battery life first involves battery capacity, charging speed (the two are actually similar issues) and batteries. attenuation. Consumers may think that to improve battery life is to increase battery capacity and energy density, but to implement engineers, it is necessary to comprehensively consider all aspects and achieve a relative balance, so it involves the discharge rate and thermal control of the battery. , which also leads to the issue of battery safety, and battery safety is not only the safety of the battery itself, but also involves the structural design of the vehicle and the safety of collisions. As for these problems, the technology of new energy vehicles is not as mature as that of traditional fuel vehicles, so it is not surprising that they have become the primary concern of consumers and manufacturers.

The motor technology is relatively mature, and most consumers do not care about the power level

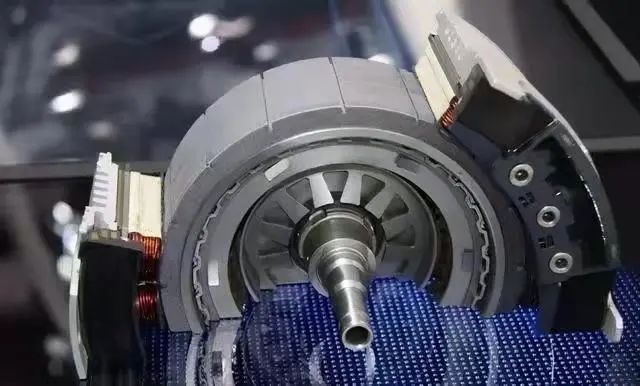

The first thing to note is that the final form of an electric vehicle should be an "in-wheel motor", and compared with the "ordinary motor" used in the current energy-based electric vehicles, the technical span between the two is very large, so I want to transition There is still a long way to go to in-wheel motors, and although the widely used permanent magnet synchronous motors and AC asynchronous motors have obvious advantages and disadvantages, the relative technologies are already very mature, such as Germany's Siemens, Nidec, Domestic brands such as BYD, Weilai, etc., have their own experience in motor manufacturing. The motor produced by them, energy utilization rate, output power, volume, failure rate, etc., are not much different from the average level of singers, while relatively comparable to batteries In terms of safety, the biggest problem involved is heat generation, but it can use the same cooling scheme as the battery, so the difficulty and cost of the motor at the manufacturing level are far less than that of the battery.

Moreover, the most intuitive thing for motor consumers is that it involves power issues, and the power level is not just what domestic consumers need to buy a family car. Moreover, the power and torque output characteristics of the motor are different from those of the internal combustion engine, and the motor can reach the maximum torque instantaneously. There is basically no need to worry about the power. For example, the acceleration time of BYD Han single-motor version can reach 7.9S, which is equivalent to the current mainstream 2.0T low-power models. The high-performance four-wheel drive version can reach an astonishing 3.9S. Some consumers consider the battery life mentioned above more than the power, and they don't care about the natural power level.

Finally, to sum up, the reason why consumers and manufacturers are more "concerned" about the battery of new energy vehicles is not only in line with the needs of consumers but also in the general direction of the development of the times, so naturally they don't care much about motors.

XINDA

XINDA