What is the difference between high-efficiency motors and ordinary motors

Date:2022-10-19 Author:Shandong Xinda Motor Co., Ltd.

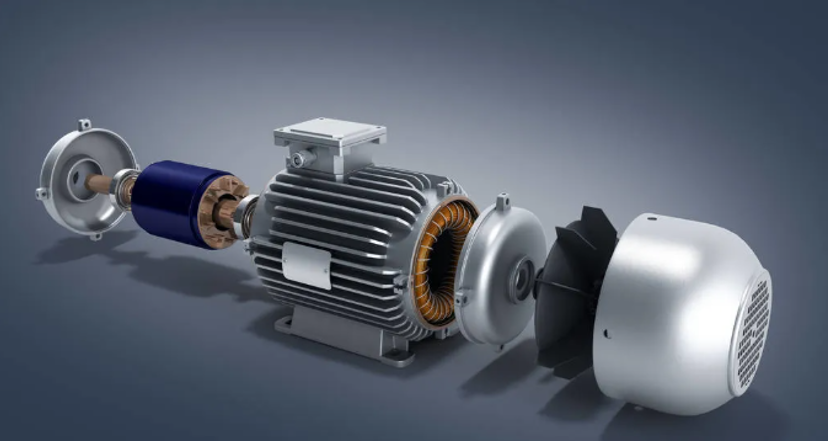

Energy-saving measures for high-efficiency motors

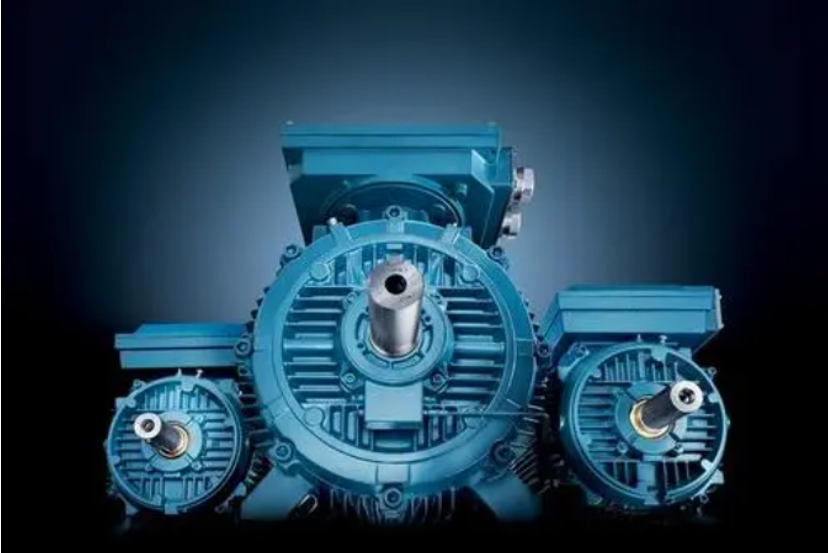

Features of high-efficiency motors

Advantages of high-efficiency motors

XINDA

XINDA