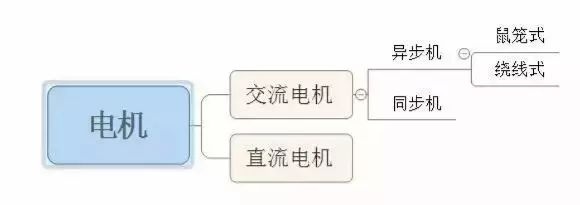

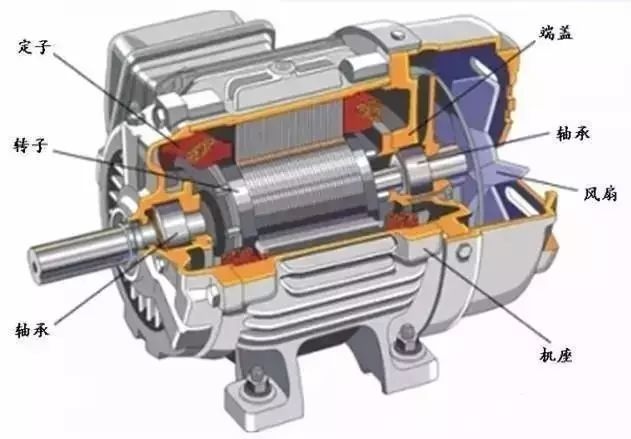

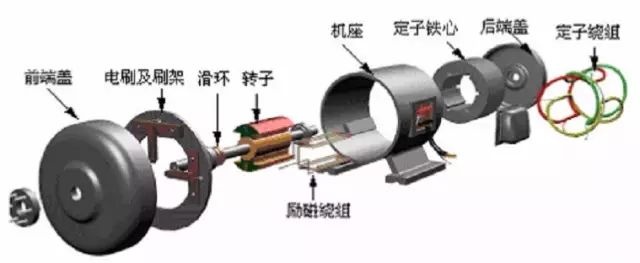

Explanation of motor knowledge, from motor classification to selection

Date:2022-09-21 Author:Shandong Xinda Motor Co., Ltd.

Production machinery that requires a large starting torque and soft mechanical characteristics, uses series or compound excitation DC motors, such as trams, electric locomotives, heavy cranes, etc.

XINDA

XINDA