The difference between oriented silicon steel sheet and non-oriented silicon steel sheet

Silicon steel, commonly known as silicon steel sheet or silicon steel sheet, is an indispensable ferrosilicon soft magnetic alloy with extremely low carbon content in the power, electronics and military industries. It is also the metal functional material with the largest output, accounting for about 1% of the world's steel output. It is a silicon-iron alloy with silicon content of 0.8%-4.8%, which is hot and cold rolled into a silicon steel sheet with a thickness of less than 1mm. Adding silicon can improve the resistivity and maximum permeability of iron, reduce coercivity, core loss (iron loss) and magnetic aging, mainly used as the core of various motors, generators and transformers.

Classification of silicon steel sheets

Silicon steel sheets can be divided into low silicon and high silicon according to their silicon content.

1 low silicon

Low silicon wafers contain less than 2.8% silicon, which has a certain mechanical strength and is mainly used in the manufacture of motors, commonly known as motor silicon steel sheets;

2 High silicon wafer

The silicon content of high silicon wafer is 2.8%-4.8%. It has good magnetic properties but is brittle. It is mainly used to manufacture transformer cores, commonly known as transformer silicon steel sheets. There is no strict boundary between the two in actual use, and high silicon wafers are often used to manufacture large motors.

Classification by production process

Can be divided into hot rolled and cold rolled

Cold rolling can be divided into two types: non-oriented and grain-oriented: cold-rolled sheets have uniform thickness, good surface quality and high magnetic properties. Therefore, with the development of industry, hot-rolled sheets tend to be replaced by cold-rolled sheets.

Classification of silicon steel sheets

Cold-rolled silicon steel sheets are divided into two types: grain-free and grain-oriented steel strips.

Grain non-oriented cold-rolled strips are usually used as iron cores for motors or welding transformers; grain-oriented cold-rolled strips are used as iron cores for power transformers, pulse transformers, and magnetic amplifiers. Cold rolled oriented thin silicon steel strip is made by pickling, cold rolling and annealing 0.30 or 0.35mm thick oriented silicon steel strip.

The cold-rolled non-oriented silicon steel sheet is a hot-rolled steel billet or continuous casting billet into a coil with a thickness of about 2.3mm. Cold-rolled electrical steel strip has the characteristics of smooth surface, uniform thickness, high stacking coefficient, good punching performance, and has higher magnetic induction and lower iron loss than hot-rolled electrical steel strip.

Using cold strips instead of hot strips to manufacture motors or transformers can reduce their weight and volume by 0%-25%. If the cold-rolled oriented strip is used, the performance is better. Using it to replace the hot-rolled strip or the low-grade cold-rolled strip can reduce the power consumption of the transformer by 45%-50%, and the working performance of the transformer is more reliable.

Definition of non-oriented silicon steel sheet

Non-oriented silicon steel sheet is a silicon steel sheet that forms a non-oriented deformation textured crystalline structure according to a certain production process.

early 20's

Williams (Williams) studied the single crystal in ferrosilicon and obtained um=1400000 in the easy magnetization axis {100} direction, and believed that it should also have excellent performance in the {100} axis in the multi-grain plate.

1926

Japanese Hondo Mao discovered that the crystallographic direction of iron is the easiest to magnetize, or the direction of the grain cube edge is the most easy to magnetize direction.

1934

American Goss (NPGoss) successfully developed the oriented silicon steel sheet in the laboratory. He used a combination of cold rolling and high temperature heat treatment to make the grains in the silicon steel sheet orderly arranged along the rolling direction, with excellent magnetic properties.

1935

Goss published an article in "TransAmer.Soc.Metals", introducing the research results, and applied for a British patent (No.442211).

In the same year, Armco Corporation of the United States began industrial production of cold-rolled grain-oriented silicon steel sheets. In the 1940s, American Armco and Allegheny produced high-quality oriented silicon steel sheets for transformers. Armco's grade is Tran-cor (Westinghouse's name is Hipersil); Allegeny's grade is Silectron (GE's name is Corosil).

1953

Japan trial-produced cold-rolled grain-oriented silicon steel sheets.

1958

Japan introduced Armco's patented technology and started the industrial production of cold-rolled oriented silicon steel sheets, and continued to improve on this basis, so that the performance of Japan's cold-rolled silicon steel sheets has reached the highest level in the world.

The magnetic permeability of the single-oriented silicon steel sheet in the direction perpendicular to the rolling direction is low. In order to overcome this shortcoming, the German vacuum melting company invented the double-oriented silicon steel sheet in the 1940s.

1957

GE and Westinghouse in the United States also made double-oriented silicon steel sheets almost at the same time. In the 1960s, Kawasaki and Yawata factories in Japan also successfully developed double-oriented silicon steel sheets. Its magnetic properties in the rolling direction and the vertical direction are similar to those of the single-oriented silicon steel sheet in the rolling direction. The grains of this silicon steel sheet are cubic.

1968

Nippon Steel Works in Japan began industrial production of high magnetic permeability oriented silicon steel sheet, its commercial name is "Orientcore Hi-B", referred to as "Hi-B"; in 1972, developed a large lattice high magnetic permeability oriented silicon steel sheet; 1981 In 1982, a small lattice high magnetic permeability oriented silicon steel sheet was developed; in 1982, Japan began to produce high magnetic permeability oriented silicon steel sheet with surface laser irradiation treatment (ZDKH), which further reduced the iron loss.

1988

Japan has also developed a high magnetic permeability oriented silicon steel sheet that uses a mechanical method to form a micro-stress method (ADMH). See the development of Nippon Steel's oriented silicon steel sheet. In the 1950s, the performance of single-oriented silicon steel sheets in several countries. ·From 1955 to 1975, the quality changes of Japanese oriented silicon steel sheets and non-oriented silicon steel sheets. From 1880 to 1970, the decline curve of iron loss of core steel sheet.

The relationship between non-oriented silicon steel sheet and oriented silicon steel sheet

1 Different silicon content

Both are cold-rolled silicon steel sheets, but the silicon content is different. The silicon content of cold-rolled non-oriented silicon steel sheet is 0.5%-3.0%, and the silicon content of cold-rolled oriented silicon steel sheet is above 3.0%.

2 different production processes

(1) Non-oriented silicon steel sheet has relatively lower process requirements than oriented silicon steel sheet. Non-oriented silicon steel sheets are hot rolled steel billets or continuous casting billets into coils with a thickness of about 2.3mm.

When manufacturing low-silicon products, the hot-rolled coil is cold-rolled to a thickness of 0.5mm after pickling.

When manufacturing high-silicon products, the hot-rolled strip is pickled (or normalized at 800-850°C and then pickled), cold-rolled to a thickness of 0.55 or 0.37mm, annealed at 850°C in a hydrogen-nitrogen mixed atmosphere continuous furnace, and then Cold rolled to a thickness of 0.50 or 0.35mm by a small reduction rate of 6-10%. Cold rolling with this small reduction ratio can make grains grow during annealing and reduce iron loss.

(2) Both cold-rolled sheets were final annealed at 850°C in a continuous furnace under a 20% hydrogen-nitrogen mixed atmosphere, and then coated with an insulating film of phosphate and chromate. After cold rolling to the finished product thickness, the supply state is mostly 0.35mm and 0.5mm thick steel strips.

The Bs of cold rolled non-oriented silicon steel is higher than that of oriented silicon steel. Oriented silicon steel sheet requires low oxide inclusion content in the steel, and must contain C0.03-0.05% and inhibitors (second phase dispersed particles or grain boundary segregation elements). The role of the inhibitor is to prevent the growth of the primary recrystallized grains and to promote the development of the secondary recrystallization, thereby obtaining a high [001] orientation.

The inhibitor itself is harmful to the magnetic properties, so after the inhibition is completed, it must be purified and annealed at high temperature. When the second phase inhibitor is used, the heating temperature of the slab must be increased to make the original coarse second phase particles solid solution, and then precipitated as fine particles during hot rolling or normalization, so as to enhance the inhibition effect.

The thickness of the cold rolled product is 0.28, 0.30 or 0.35mm. Cold rolled oriented thin silicon steel strip is made by pickling, cold rolling and annealing 0.30 or 0.35mm thick oriented silicon steel strip.

Compared with cold-rolled non-oriented silicon steel, oriented silicon steel has much lower loss than non-oriented silicon steel, and has strong magnetic directionality; it has superior high permeability and low loss characteristics in the rolling direction that is easy to magnetize. The iron loss of the oriented steel strip in the rolling direction is only 1/3 of the transverse direction, the ratio of magnetic permeability is 6:1, the iron loss is about 1/2 of the hot-rolled strip, and the magnetic permeability is 2.5 times that of the latter. .

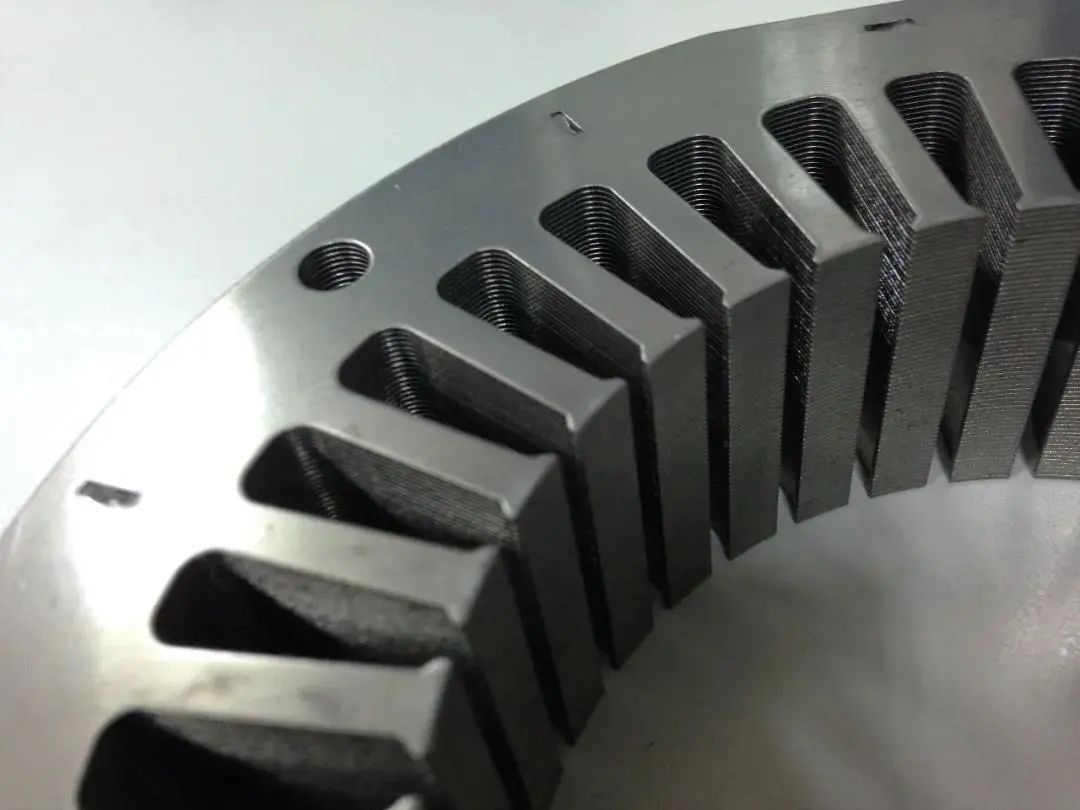

3 The grain structure is different

The grains of oriented silicon steel are ordered, and the grains of non-oriented silicon steel are disordered. Non-oriented silicon steel is mainly used in stators and rotors of motors, compressors, large hydro-generator sets and other equipment. Oriented silicon steel is generally used in transformer cores and some motors.

Generators and transformers have the same requirements for silicon steel sheets: both require low iron loss, good magnetization characteristics, and high lamination coefficients, but transformers generally use oriented silicon steel sheets. Non-oriented silicon steel sheets for generators.

4 Different properties and uses

Due to the different performance characteristics of the two, there are differences in the direction of use: the main purpose of the cold-rolled non-oriented silicon steel sheet is for the manufacture of generators, so it is also called cold-rolled motor silicon steel. The main purpose of cold-rolled oriented silicon steel strip is for transformer manufacturing, so it is also called cold-rolled transformer silicon steel.

Silicon steel sheet performance index

1. Low iron loss. The most important indicator of quality, all countries in the world divide grades by iron loss value. The lower the iron loss, the higher the grade and the higher the quality.

2. High magnetic induction intensity. Under the same magnetic field, a silicon steel sheet with higher magnetic induction can be obtained, and the volume and weight of the motor or transformer iron core made by it are relatively small, which can relatively save silicon steel sheet, copper wire and insulating materials.

3. High stacking coefficient. The surface of the silicon steel sheet is smooth, flat and uniform in thickness, and the stacking coefficient of the iron core is improved.

4. Good punchability. This is even more important for the manufacture of small, miniature motor cores.

5. The surface has good adhesion and weldability to the insulating film, which can prevent corrosion and improve the punching property.

6. The phenomenon of magnetic aging is small. ·Silicon steel sheet shall be delivered after annealing and pickling.

1 Hot-rolled silicon steel sheet for electrical use (GB5212-85)

The hot-rolled silicon steel sheet for electrical use is made of ferrosilicon soft magnetic alloy with low carbon loss, and is hot-rolled into a sheet with a thickness of less than 1mm. Hot-rolled silicon steel sheet for electrical use is also called hot-rolled silicon steel sheet. Hot-rolled silicon steel sheets can be divided into low silicon (Si≤2.8%) and high silicon (Si≤4.8%) steel sheets according to their silicon content.

2 Cold-rolled silicon steel sheet for electrical use (GB2521-88)

It is made of electrical silicon steel containing 0.8%-4.8% silicon and is cold-rolled. Cold-rolled silicon steel sheets are divided into two types: grain-free and grain-oriented steel strips. Cold-rolled electrical steel strip has the characteristics of smooth surface, uniform thickness, high stacking coefficient, good punching performance, and has higher magnetic induction and lower iron loss than hot-rolled electrical steel strip.

Using cold strips instead of hot strips to manufacture motors or transformers can reduce their weight and volume by 0%-25%. If the cold-rolled oriented strip is used, the performance is better. Using it to replace the hot-rolled strip or the low-grade cold-rolled strip can reduce the power consumption of the transformer by 45%-50%, and the working performance of the transformer is more reliable.

Used in the manufacture of motors and transformers. Generally, grain-oriented cold-rolled strips are used as the state of motors or welding transformers, etc.; grain-oriented cold-rolled strips are used as iron cores for power transformers, pulse transformers, magnetic amplifiers, and the like. Steel plate specifications and dimensions: thickness of 0.35, 0.50, 0.65mm, width of 800-1000mm, and length of ≤2.0m.

3 Hot-rolled silicon steel sheet for household appliances (GBH46002-90)

The grade of hot-rolled silicon steel sheet for household appliances is represented by J (home), D (electricity), and R (hot-rolled), that is, JDR. The number after JDR is the iron loss value * 100, and the number after the horizontal line is the thickness of the steel plate (mm) * 100. The electromagnetic performance requirements of hot-rolled silicon steel sheets for household appliances can be slightly lower, and the minimum iron loss value (P15/50) is 5.40W/kg. Usually delivered without washing.

Differential motors used in various household appliances such as electric fans, washing machines, vacuum cleaners, range hoods, etc.

There are two ways to distinguish grain-oriented silicon steel sheets

eye view

Oriented silicon steel sheet is off-white;

hand folding

Take a piece of silicon steel and fold it twice by hand, the oriented one will drop off gray-white slag, and it will break after repeated two or three times.

XINDA

XINDA