Disadvantages of permanent magnet motors

Date:2022-07-19 Author:Shandong Xinda Motor Co., Ltd.

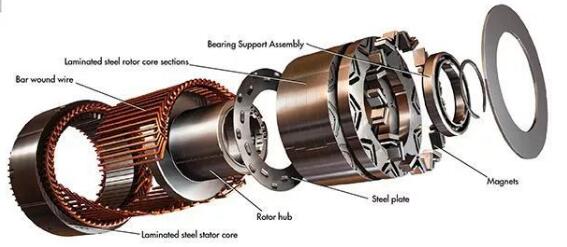

In permanent magnet motors, the stator may use concentrated (short pitch) windings if torque ripple is not a concern, but distributed windings are common in larger permanent magnet motors.

Since permanent magnet motors have no mechanical commutator, the inverter is critical for controlling the winding current. Unlike other types of brushless motors, permanent magnet motors do not require current to support their magnetic field.

So if it is small or light, a permanent magnet motor can provide the most torque and is probably the best choice. No magnetizing current also means better efficiency at the "sweet spot" load - where the motor performs best.

Furthermore, while permanent magnets bring performance advantages at low speeds, they are also a technical "Achilles heel". For example, as the speed of a permanent magnet motor increases, the back EMF approaches the inverter supply voltage, making it impossible to control the winding current. This defines the base speed of a universal permanent magnet motor, and typically represents the maximum possible speed for a given supply voltage in surface magnet designs.

At speeds greater than the base speed, the IPM uses active field weakening, where manipulating the stator current deliberately depresses the magnetic flux. The range of speeds that can be reliably implemented is limited to around 4:1. As before, this limit can be achieved by reducing the number of winding turns and accepting greater cost and power losses in the inverter.

The need for field weakening is speed dependent and has associated losses regardless of torque. This reduces efficiency at high speeds, especially at light loads.

In an electric vehicle driving on the highway, this is very serious. Permanent magnet motors are often favored by EVs, but the efficiency benefits are questionable when calculated in real driving cycles. Interestingly, at least one prominent EV manufacturer has switched from PM to induction motors.

Other disadvantages include the fact that it is difficult to manage under fault conditions due to its inherent back EMF. Even if the frequency converter is disconnected, as long as the motor is spinning, current will continue to flow through the winding fault, causing cogging torque and overheating, both dangerous.

For example, field weakening at high speeds can cause uncontrolled power generation due to inverter shutdown, and the inverter's DC bus voltage can rise to dangerous levels.

Besides those permanent magnet motors with samarium cobalt magnets, operating temperature is another important limitation. And high motor current due to inverter failure can cause demagnetization.

The maximum speed is limited by the holding force of the mechanical magnets. If a permanent magnet motor is damaged, repairing it usually requires a return to the factory, as safely extracting and disposing of the rotor is difficult. Finally, recycling at end-of-life is also cumbersome, although the current high value of rare earth materials may make such materials more economically viable.

Despite these shortcomings, permanent magnet motors remain unmatched for low speed and sweet spot efficiency, and they are both very useful where size and weight are critical.

XINDA

XINDA