BMW electrification from the industrial metaverse

On June 23, the BMW Rida factory, which cost 15 billion yuan and covers an area of 2.9 million square meters, was officially opened. The Lida plant is BMW's third vehicle plant in Shenyang, and it is the largest single investment in BMW's history in China, which shows BMW's practical actions and ambitions to "home in China".

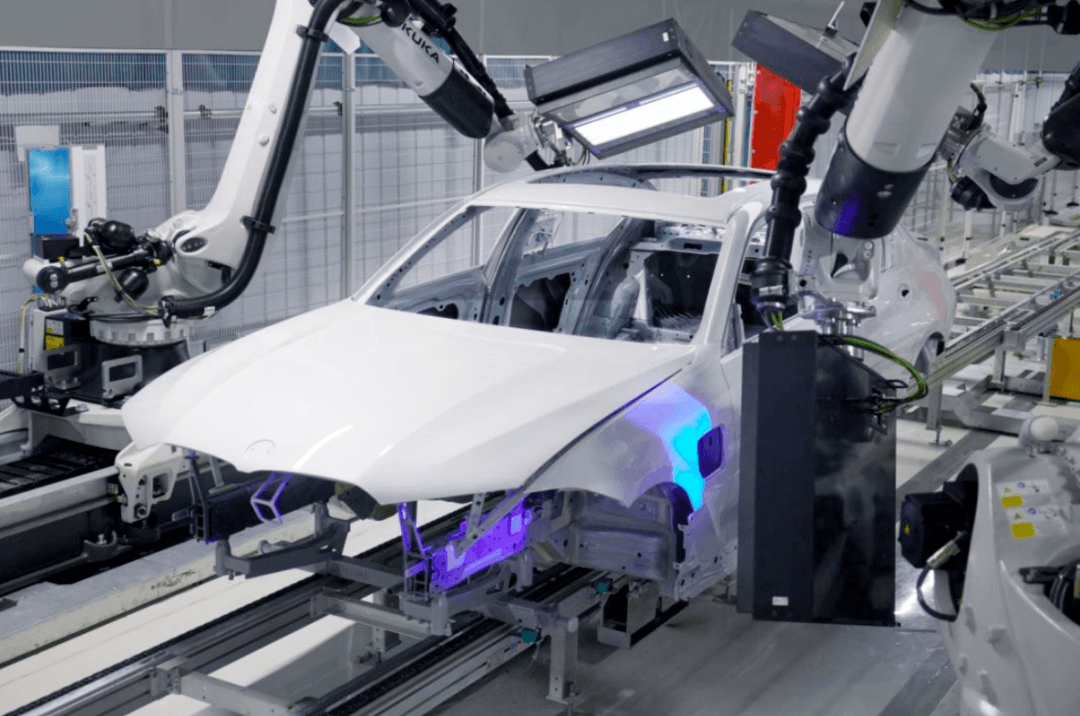

Starting from the three dimensions of "lean, green and digital", BMW has built the Lida plant into a new paradigm for producing cars. Lean production is naturally the standard configuration of BMW as a luxury car brand, and green emissions are a major responsibility BMW has to undertake as a global enterprise. However, in the Rida factory, the most surprising and surprising thing is BMW's digitalization!

Based on BMW's BMW iFACTORY strategy, the digitization of the Lida factory is no longer the digitization of the physical three-dimensional universe in the traditional sense, but the digitization of the virtual intelligent industrial metaverse!

Enter the Industrial Metaverse

For most people, the metaverse is probably still new and unfamiliar, let alone the industrial metaverse! But in fact, the industrial metaverse is a conceptual branch of the metaverse, and it is still the metaverse in essence.

If it is a metaverse, then it must have an immersive experience; if it is a metaverse, then it must be decentralized. However, the immersive experience and decentralization in the industrial metaverse is not only related to users, but more importantly, the immersive work and modular production of designers and producers.

Production in the industrial metaverse will be turned upside down compared to traditional factories.

First, from user reverse drive to user forward drive. In the traditional design and production process, all starting points must be based on the needs of users. However, it often takes several years from the design of a car to the launch of production. Whether the design of that year can still meet the needs of today's users is still a big question mark?

In the industrial metaverse, however, such problems will cease to exist. First of all, in the industrial metaverse, users can also deeply participate in design and experience on the platform. For example, this time BMW has released a cloud mobile game called "BMW iFACTORY Experience Tour". You can choose a character and visit every part of the Lida factory at will, watch the production of each component, and experience the design of automotive products. With the deep participation of users, BMW can grasp the latest needs of current users.

Secondly, the industrial metaverse breaks the geographical restrictions, so it can use the collision and friction of virtual, real, different spaces here and there through human-computer interaction and multi-person collaboration, so as to inspire more spiritual inspiration. Make a design that meets user needs and exceeds user imagination. Then, by building a virtual scene, you can interactively experience the final design effect. Therefore, the design in the industrial metaverse will greatly improve the efficiency of design and save the cost of design.

Of course, the improvement of efficiency and cost saving are the benefits that the Industrial Metaverse brings to BMW. For users, in-depth participation can deepen the cognition of products, reflect on their own needs, and improve their understanding of online and offline activities. Dimensional experience.

Second, use algorithms to bridge the boundaries from design to production. In the process of a new product being put on the market at first, the production process is often slow or defective because the production process does not meet the technological requirements of the product, and the production operation cannot keep up with the changes in the needs of users, so it has to go through a difficult period of time. production ramp-up period. During this time, OEMs often endure huge pains.

But in BMW's Rida factory, the artificial intelligence computer vision system can take 100,000 photos in 100s and perform deep learning, so as to train the eyes to identify flaws in products.

In addition, through the industrial metaverse, the production and operation process can be simulated intelligently, so that problems can be found more intuitively, and they can be maintained and solved in a timely manner. Moreover, in the Lida factory, products, people, and processes are connected through the Internet of Things, and the production process can be tracked with high precision, avoiding possible risks and problems, and ensuring the process quality of each process.

Once the boundaries between design and production are broken, the road to the user journey becomes shorter and shorter.

Third, alleviate the uncertainty of delivery. Under the double obstruction of the repeated epidemic and the chip crisis, many users often wait for three months and three months for delivery, which is very troublesome.

The solution given by BMW is still accurate simulation through the industrial metaverse. BMW took the lead in applying the yard management system, which combines real-time logistics data with 3D models to simulate various logistics scenarios in an all-round way and generate more reasonable yard planning, so that personnel and container management can be mobilized more scientifically.

Although the epidemic and chips are uncontrollable, the controllable factors must be firmly in hand.

Last but not least, the Rida factory itself is a product of the industrial metaverse. From factory planning, architectural design, production line layout to equipment debugging, everything happens in the industrial metaverse. With an area of 2.9 million square meters, it only took more than two years from design to production. The Industrial Metaverse has greatly improved the construction efficiency of the Rida factory.

Through the construction of the Industrial Metaverse and the production through the Industrial Metaverse, the Rida Factory can be said to have come from the Industrial Metaverse to the Industrial Metaverse.

Open up the industrial metaverse

It is undeniable that BMW's current electrified products have certain problems, the market recognition is not high, and the sales are relatively unsatisfactory. Therefore, in order to save BMW's image in the electric vehicle market, the Rida plant, which is oriented towards electric vehicle production, may play a role in turning the tide.

It is reported that the new BMW i3 has been put into production at the Rida plant. The future of the BMW i3 is unknown, but even under the blue sky and white clouds of BMW, the i3 in the past could only reluctantly exchange for more than 100 sales per month through constant price cuts.

Therefore, the first model BMW chose to put into production at the Lida plant is the new BMW i3, which may have the meaning of standing up from where it falls. Thanks to the new production method and production concept of the industrial metaverse, the new BMW i3 may have some new changes in intelligent experience, design feel and handling performance.

Gao Le, President and CEO of BMW Group Greater China , said: "For BMW Group, 'Home in China' is not only a promise, but also a tangible and continuous effort. The electrification strategy is the key to our sustainable development goals. , the Rida plant will play an important role in accelerating the electrification transition."

Gao Le, President and CEO of BMW Group Greater China , said: "For BMW Group, 'Home in China' is not only a promise, but also a tangible and continuous effort. The electrification strategy is the key to our sustainable development goals. , the Rida plant will play an important role in accelerating the electrification transition."

In addition to the new BMW i3, BMW will also launch four pure electric models in 2022, including the BMW iX3, i4, iX and i7 . And with the gradual release of the production capacity of the Lida plant, BMW's production in China will jump to 830,000 vehicles. This also means that opening the electric vehicle market as soon as possible has become a top priority for BMW Brilliance.

Starting from the industrial metaverse, whether BMW can remove its inherent label in the electric vehicle market and continue its glorious history in the fuel vehicle market, the mystery is written by BMW, and the answer will be revealed by you and me!

XINDA

XINDA