What is the working principle of a kitchen waste disposer?

Date:2025-11-12 Author:Shandong Xinda Motor Co., Ltd.

Let's analyze the working principle of a food waste disposer (also commonly known as a "food waste grinder" or "kitchen waste disposer") in detail.

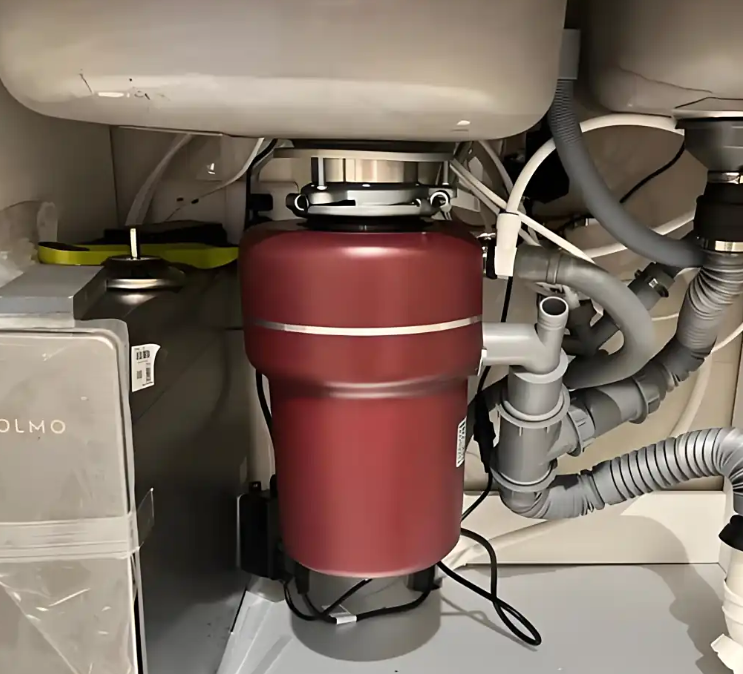

Simply put, its core principle is: a motor drives a grinding disc to rotate at high speed, using centrifugal force to throw food waste onto the inner wall of the grinding ring. Under the continuous impact and friction of the grinding hammers and grinding ring, the waste is pulverized into fine particles, which are then flushed down the drain with water.

Below, we will explain in detail step by step:

Core Components

To understand its working principle, we first need to understand its key components:

1. Grinding Chamber (Pulverizing Chamber): The space that holds food waste, usually made of stainless steel for corrosion resistance.

2. Grinding Disc (Rotating Disc): Located at the bottom of the chamber, connected to the motor, it can rotate at high speed.

3. Grinding Hammers (Impact Hammers): Usually small, protruding hammers made of stainless steel, fixed to the grinding disc and rotating with it, responsible for impacting and pulverizing the waste.

4. Grinding Ring (Fixed Tooth Ring): A serrated ring installed on the inner wall of the grinding chamber, which works in conjunction with the rotating grinding hammer to crush and grind the waste.

5. Motor: Provides power. There are two types:

* AC Motor: High torque, strong power, better at handling hard waste (such as small bones), long lifespan, but also relatively heavier and noisier.

* DC Motor: High starting torque, high speed, lightweight, low noise, but may be slightly inferior to AC motors when handling particularly hard waste.

6. Splash Shield: Prevents food scraps and water from splashing out during grinding.

7. Overload Protection System: Automatically cuts off power to protect the motor when the machine jams or is overloaded.

---

Workflow (Detailed Step-by-Step Explanation)

Step 1: Deposit and Rinse

* You pour food waste (such as vegetable leaves, leftovers, fruit peels, etc.) into the sink.

* Simultaneously or immediately afterward, turn on the cold water tap. The water flow serves two key functions:

1. Assisted grinding: helps flush waste towards the center of the grinding disc.

2. Motor cooling: cools the motor during the grinding process.

3. Flushing and transporting: smoothly flushes the ground particles into the sewer.

Step Two: Start-up and Grinding

· Turn on the power switch of the recycling unit.

· The motor starts, driving the grinding disc and its grinding hammers to rotate at high speed (usually 1400-2800 rpm).

· Under centrifugal force, food waste is thrown to the periphery of the grinding chamber, adhering tightly to the inner wall of the grinding ring.

Step Three: Grinding and Refining

· The rotating grinding hammers and the stationary grinding ring create continuous impact, shearing, and friction.

· This process is like countless tiny hammers constantly pounding and grinding food on a rough grinding disc.

· Hard waste (such as small bones and fruit pits) is first crushed, while soft waste (such as fruit and vegetable peels) is torn and ground.

Step 4: Discharge and Filtration

• The pulverized particles continue to circulate within the chamber until they become small enough (typically less than 2 mm in diameter) to pass through the gap between the grinding disc and the grinding ring.

• At this point, water flow flushes these fine particles out of the grinding chamber, into the sewer, and smoothly through the household plumbing system.

• Some well-designed recyclers also utilize centrifugal force for "secondary filtration," where heavier particles remain at the bottom of the chamber to be ground again, ensuring that only sufficiently fine particles are discharged.

---

Two Main Grinding Technologies

1. Bladeless Grinding Technology (Mainstream Technology)

• This is the technology used in the vast majority of household food waste recyclers. Note that it does not have sharp rotating blades like those in a blender.

• It relies on the interaction between the grinding hammer and the grinding ring mentioned above. This design is safer; even if a hand is accidentally inserted (when not powered on), there will be no cuts. It also effectively handles various soft and hard wastes and is less prone to jamming.

2. Blade Sharpening Technology (Less Common)

* This type does indeed have sharp, rotating blades, like a blender. It primarily pulverizes waste by cutting.

* The disadvantages are that it's more prone to tangling (especially with fibrous waste like celery stalks and corn silk), and the blades can be damaged by impact with hard objects.

---

Important Precautions and Safety Tips

* Always operate under running water: Operating without water flow will severely damage the machine.

* Cold water is recommended: Cold water keeps the grease in food scraps solid, making them easier to pulverize and flush away. Hot water melts the grease, but it may re-solidify in the colder pipes, causing blockages.

* Can handle: Most kitchen waste, such as peels, vegetable leaves, leftover food, eggshells, and small bones (chicken bones, fish bones).

* Avoid handling:

- High-fiber items: Corn husks, celery stalks, water chestnut husks, animal hair, etc. (easily tangled).

-Hard materials: Large pieces of pork bones, shells, fruit pits (too hard, causing significant wear and tear on the machine).

-Non-food items: Plastics, metals, glass, textiles, etc.

-Hot oil and grease.

• Safety design: Modern recycling bins typically feature a bladeless design and a splash guard, greatly improving safety. Many models also have automatic overload protection to prevent motor burnout.

In summary: A food waste recycler is like a high-speed centrifugal grinder installed under your sink. It physically breaks down kitchen waste, then uses water flow to send it into the existing sewage system, achieving immediate and harmless treatment of kitchen waste, greatly reducing the burden of household waste sorting and the odor problem of garbage bags.

XINDA

XINDA