How to choose the motor under different operating conditions?

Frequent start-stop, heavy-load start-up, and constant torque/constant power are three typical operating conditions. The selection logic is disassembled to help you avoid common minefields and achieve efficient matching of the power system.

01

Frequent start-stop conditions: heat dissipation and mechanical shock are the core challenges

Typical scenarios: automated sorting lines, stamping machines, elevator door operators, and injection molding machine opening and closing

Key pain points:

Heat accumulation is fatal: the instantaneous current of start-stop can reach 6-8 times the rated current, and insufficient heat dissipation can directly burn the insulation layer.

Mechanical shock: Repeated starting and stopping accelerates bearing wear and causes vibration and noise

Braking energy processing: The feedback energy generated by braking may damage the drive

The "three highs" principle of selection:

High heat dissipation capacity: forced air cooling motor, insulation grade ≥H grade (180℃)

High mechanical strength: cast aluminum housing + reinforced bearing, bearing model suffix with "C3" clearance

High start-stop frequency: variable frequency motor/servo motor, the allowed start-stop frequency is ≥300 times/hour

02

Heavy-load starting conditions: Breaking through "static friction" is the key to success

Typical scenarios: ball mills, crushers, compressors, large fans

Physical nature : Starting torque needs to overcome the static inertia of the equipment + load resistance, usually 150%-200% of the rated torque

Core selection formula: Starting torque requirement = load static friction torque × safety factor (≥1.5)

Motor solution comparison:

High-slip motors : Small and medium-sized equipment (≤75kW), large starting current, and low energy efficiency

Wound rotor motor : Large and heavy-duty equipment requiring maintenance of slip rings and carbon brushes

Frequency conversion soft start: Precise control scenarios require additional investment in frequency converters

Practical skills:

Torque check : Check the motor Tn curve to ensure that the starting torque is greater than the load requirement.

Use reduced voltage starting with caution : Y-Δ starting torque is reduced to 33%, only suitable for light loads

03

Performance Game of Constant Torque vs. Constant Power Conditions

(1) Constant torque working condition - low speed needs to be "powerful"

Typical scenarios: conveyor belts, winches, extruders

Characteristics: Load torque is independent of speed (such as lifting heavy objects)

Key points for motor selection:

Ordinary asynchronous motors are preferred: their natural characteristics are close to constant torque

Variable frequency motors are required for speed regulation: ordinary motors have poor heat dissipation at low speeds

Power calculation formula: P = T·n/9550 (T is torque in Nm, n is speed in r/min)

(2) Constant power working condition - no "loss of power" at high speed

Typical scenarios: machine tool spindles, centrifuges, electric vehicle drives

Features: Constant output power, the higher the speed, the smaller the torque (such as machine tool cutting)

Key points for motor selection :

Wide speed regulation permanent magnet synchronous motor: constant power range up to 1:4

Weak magnetic control capability: Maintain power through weak magnetic field in high-speed area

04

The neglected system matching problem

Neglected system matching issues. Even if the motor is correctly selected, these errors can still lead to failures:

Inertia mismatch : When the load inertia is > 5 times the motor rotor inertia, the servo system is prone to oscillation.

Voltage sag : A voltage drop of > 15% at the moment of heavy-load startup may cause the contactor to trip.

Harmonic interference : The inverter output terminal is not equipped with a reactor, resulting in motor insulation breakdown

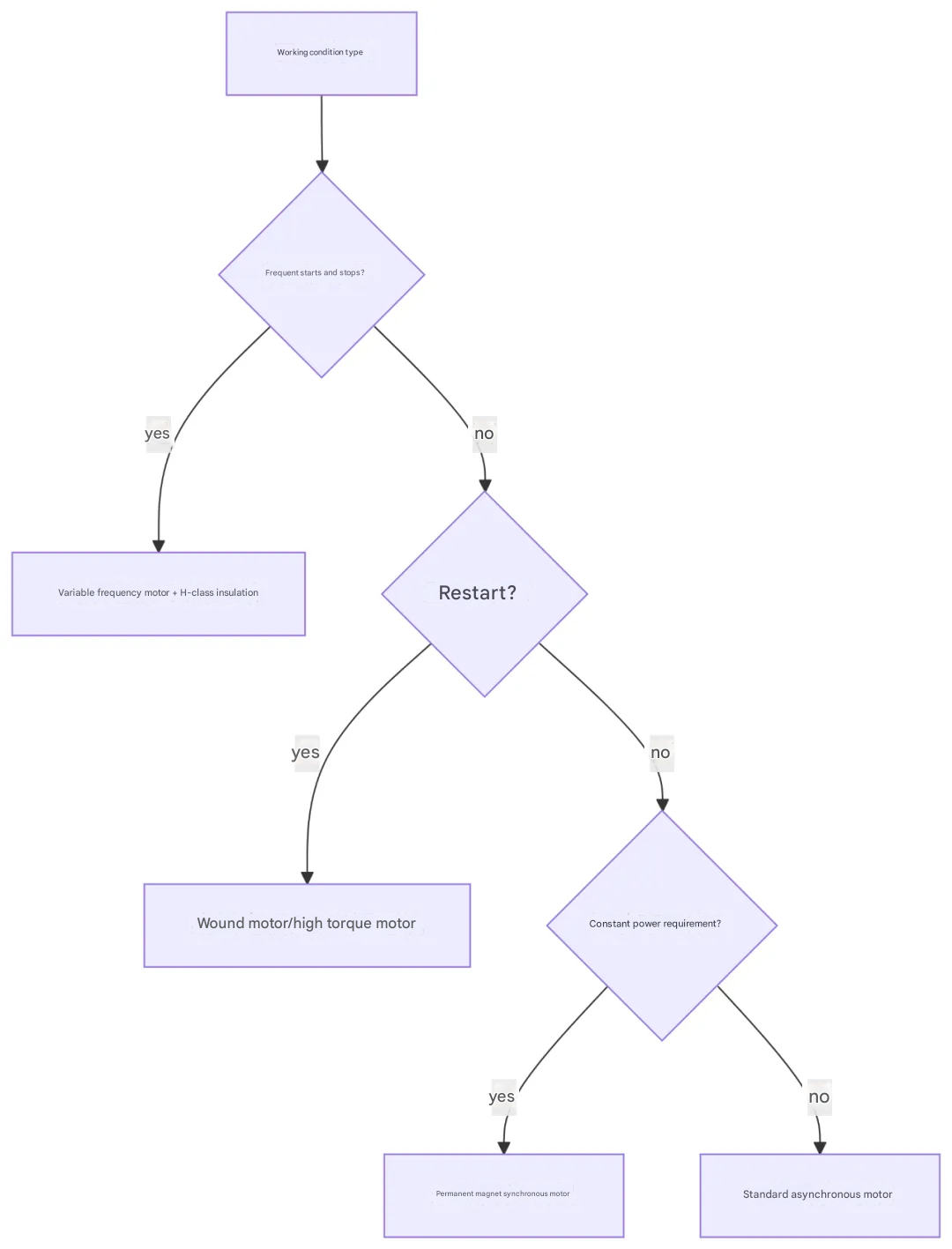

Ultimate selection decision tree

Model selection is a technology, but also an economics

The motor procurement cost accounts for only 10% of the total life cycle cost. The correct selection plan can improve capacity utilization by reducing failure downtime, optimize energy efficiency and reduce operating costs, extend life and reduce spare parts expenses, creating returns for your business that far exceed the value of the hardware.

XINDA

XINDA