How to evaluate the energy-saving effect of motors? How to calculate the energy-saving percentage?

Regarding the topic of improving the efficiency of the motor itself, how much energy can be saved for every ? This is a question that everyone is very concerned about. But how to compare and analyze the efficiency improvement and energy saving effect? Many people confuse the percentage point of motor efficiency improvement with the overall energy saving effect.

We can use the Chinese saying "what is saved is earned" to analyze the energy saving effect of the motor more intuitively, that is, to analyze the change of the original wasted electricity. Table 1 shows the energy consumption, output mechanical work, and absolute loss of a 4-pole 200kW three-phase asynchronous motor with different energy efficiency levels when working for one hour.

Table 1 Comparison of energy consumption and output energy of a 4-pole 200kW motor working for 1 hour

project

YE3

YE4

YE5

efficiency%

96

96.7

97.4

Input power (kWh)

200

200

200

Output mechanical energy (kWh)

192

193.4

194.8

Energy consumption per hour (kWh)

8

6.6

5.2

Relative to YE3 saving%

17.5

35

We compare and analyze the losses of YE4 and YE5 motors relative to YE3 motors in Table 1. A 4-pole 200kW YE3 motor consumes 8 kWh of electricity when it consumes 200 kWh of electricity, while a 4-pole 200kW YE4 and YE5 motor consumes 6.6 and 5.2 kWh of electricity when it consumes 200 kWh of electricity, respectively, which is 1.4 and 2.8 kWh less, respectively. The electricity saved accounts for 17.5% and 35% of the energy of 8 kWh, respectively.

The efficiency of the YE4 motor of this specification is increased by 0.7 percentage points compared to the YE3 motor, and the relative energy saving effect is 17.5%. For every 1 percentage point increase in efficiency, the energy saving effect is 25%.

From the above calculation process, we can understand the energy-saving effect of motor efficiency improvement. This article only calculates the energy-saving effect of a single product. If the motor's single-machine energy saving can be combined with the system energy saving and a systematic transformation can be carried out, the overall energy-saving effect will be more obvious.

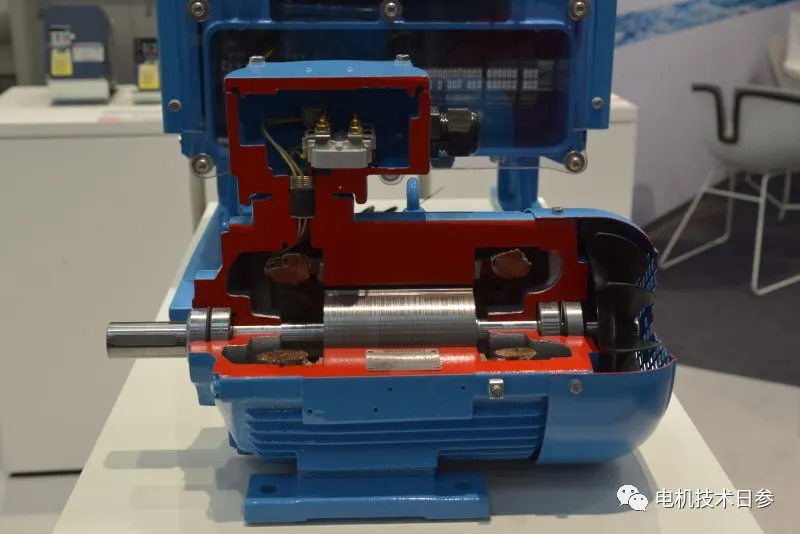

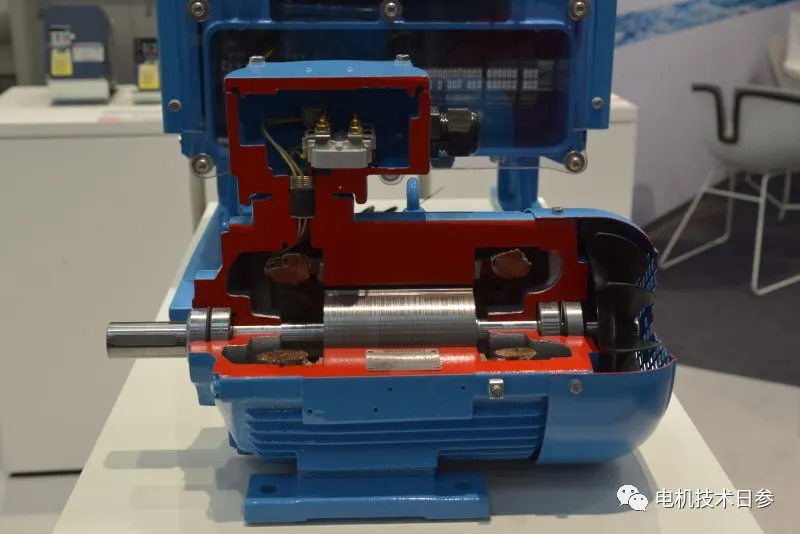

In the cases of permanent magnet remanufacturing, direct drive transformation and frequency conversion control transformation of motors, the energy-saving effect of the equipment system is very obvious, which is also a reflection of the benefits of motor production and remanufacturing after efficiency improvement.

project

YE3

YE4

YE5

efficiency%

96

96.7

97.4

Input power (kWh)

200

200

200

Output mechanical energy (kWh)

192

193.4

194.8

Energy consumption per hour (kWh)

8

6.6

5.2

Relative to YE3 saving%

17.5

35

XINDA

XINDA