Analysis of the characteristics and causes of insulation failure of motor products to ground

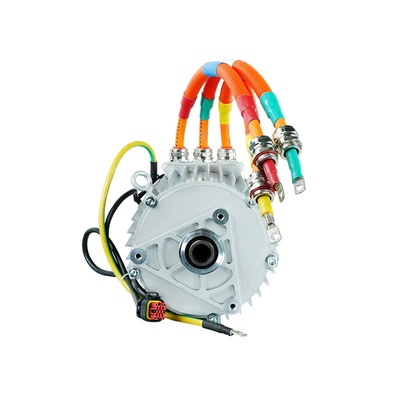

Insulation performance to ground is a performance requirement that any electrical product must have, and motor products are no exception. The live parts of the motor should be effectively isolated from other parts by the necessary insulating medium, and different insulation structures involve different insulating materials.

According to the location of occurrence, the insulation failure to ground of motor products can be divided into insulation failure to ground between winding and core, winding and shaft (for wound rotor motors), winding and base, winding and end cover, and lead wire and related components.

The insulation failure between the winding and the core to the ground mostly occurs at the slot position, which is mostly related to the springing of the core and the expansion and shaping of the end of the winding. This type of problem is more serious for products with a high winding slot fill rate. Another location for the winding to the ground is inside the slot. The main reason for this problem may be unevenness in the core slot, foreign matter, etc., resulting in damage to the insulation at the bottom of the slot, or it may be caused by the insulation size in the slot not meeting the requirements or twisting.

The possibility of repair varies with different insulation treatment processes; most motor manufacturers use vacuum pressure varnishing, and the insulating varnish becomes an irreversible solid after curing, so it is difficult to repair, especially the insulation fault in the core slot, which is basically irreparable. For the ground fault between the winding and the core slot, due to the special shape of the slot, when a ground fault occurs, it is very likely that the paint film of the electromagnetic wire has been damaged. Even if the ground insulation fault is repaired, the possibility of inter-turn insulation is also high.

From a theoretical analysis, there is no substantial contact between the motor winding ends and the base and end cover, that is, there is a certain spatial distance between the winding and the base and end cover. However, the physical space is relatively tight, especially when the winding ends are not shaped in a standardized manner. When the motor stator is pressed into the base, especially after being assembled into a complete machine, there is substantial contact between the winding and the base or end cover, which can easily cause insulation failure to the ground.

This type of fault generally has certain regularity. The first is the concentration of product specifications, and the second is the relatively fixed ground fault point. This type of fault point is mostly concentrated in the welding of the winding lead wire and the main wire, and the position where the lead wire exits the machine base.

In order to avoid such problems, the processability of winding processing is crucial; the winding opening position, size, relative position control with the machine base outlet, and the distribution of lead wires will affect the final overall effect.

The insulation failure of the rotor winding to the ground is a type of failure unique to wound rotors. The causes of the insulation failure in the slot are similar to those of the ground failure in the stator slot. The ground failure of the winding and the shaft is mainly concentrated at the end of the winding. When the end is poorly shaped or the manufacturing quality of the metallic rotor bracket is poor, it will cause insulation failure to the ground.

Both the stator lead wire and the rotor lead wire must pass through a certain path. When there are sharp burrs or sharp edges in the path, the insulating sheath of the lead wire may be damaged, causing a direct ground fault.

For the stator part, this type of fault is prone to occur at the machine base outlet, and the main reason is that the quality of the machine base blank is poor. For the rotor part, especially when the lead is led out through a deep hole, the position where the lead enters the deep hole and the position where the lead exits the shaft hole are both prone to problems. It should be emphasized that metal chips in mechanical processing and rough operations in the assembly process are the biggest enemies of lead-to-ground faults.

From the anatomical analysis of ground faults, it was found that ground faults are caused by typical human factors. Material selection is certainly important, but the refinement and standardization of process requirements and implementation are the most effective means to avoid this problem.

XINDA

XINDA