5D200GN-RV30

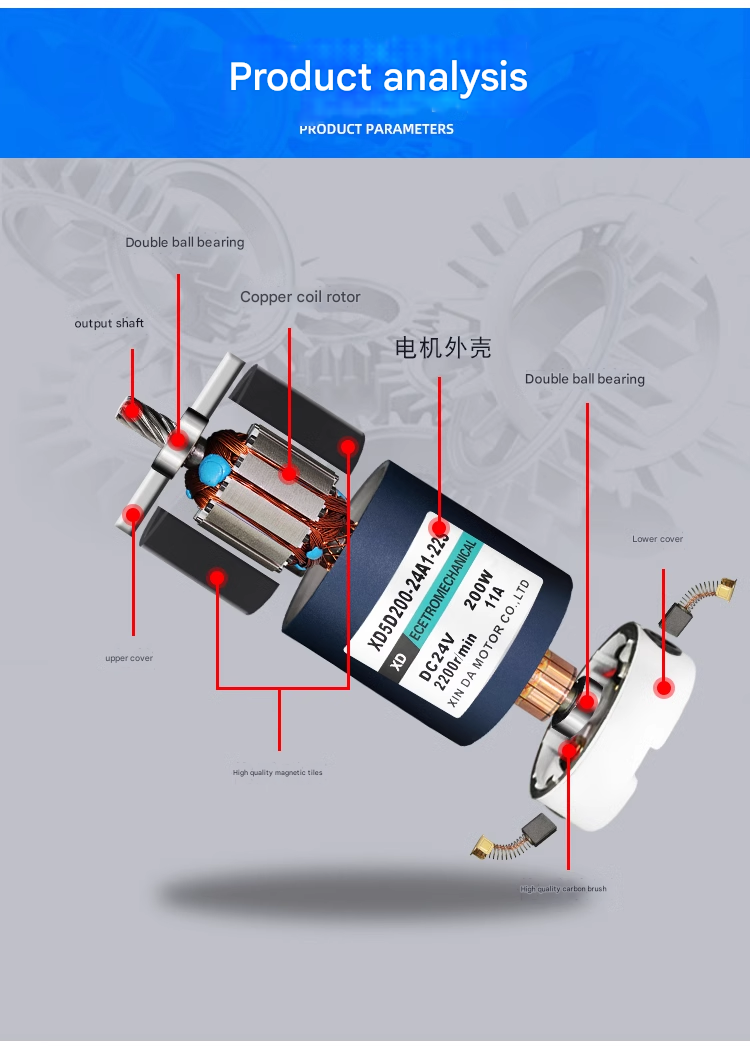

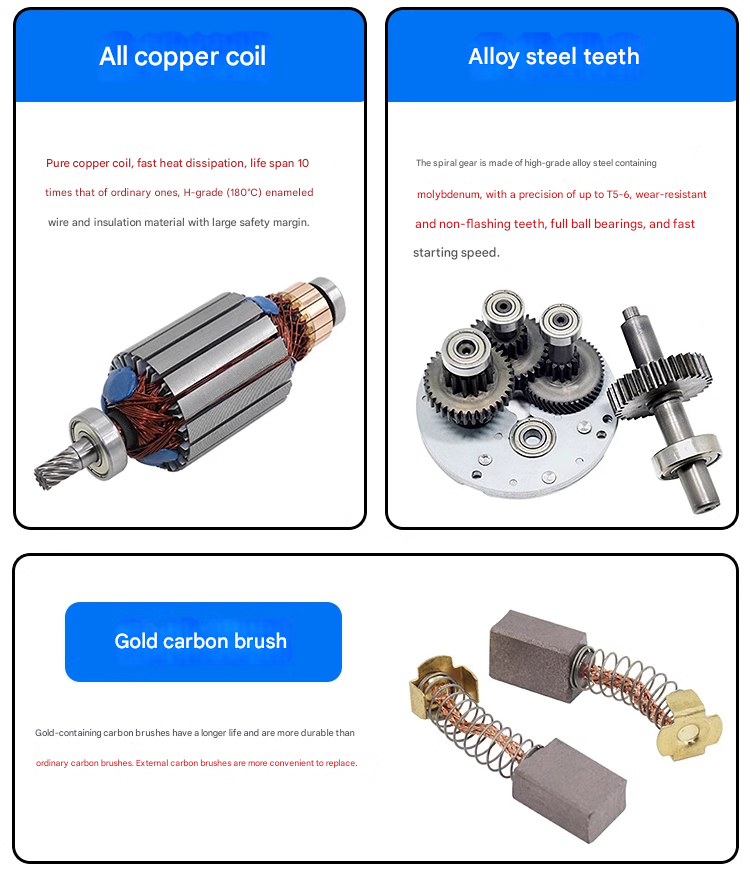

Pure copper coil, fast heat dissipation, life span 10 times that of ordinary ones, H-grade (180℃) enameled wire and insulation material with large safety margin.

Alloy steel teeth

Spiral gears made of high-grade alloy steel containing molybdenum, with a precision of up to T5-6, wear-resistant and non-flashing teeth, full ball bearings, fast starting speed

Gold-containing carbon brush

Gold-containing carbon brush, longer life and more durable than ordinary carbon brushes, external carbon brush, more convenient replacement

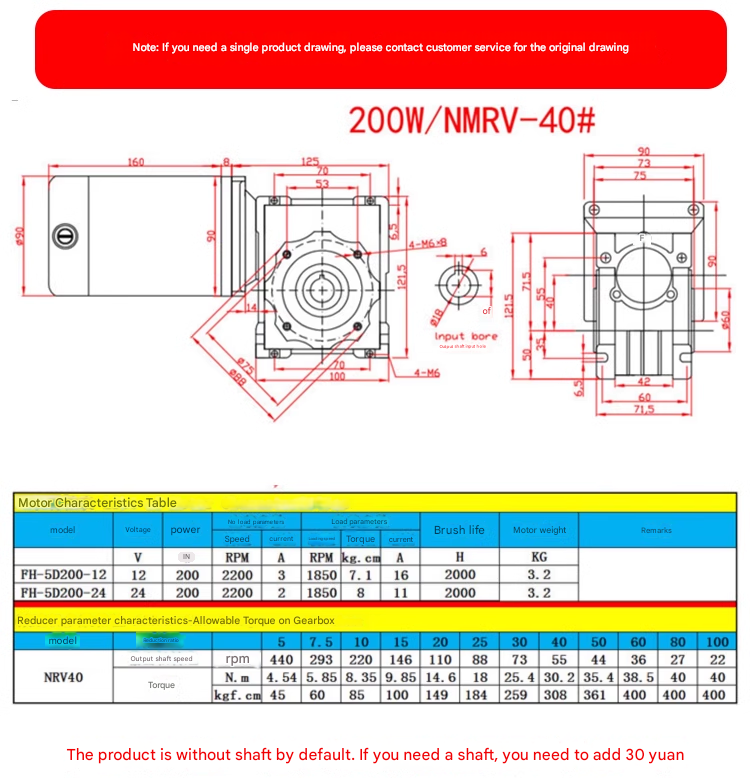

What does the torque in the motor parameter table usually represent?

The standard torque of the motor is 10KG.CM. Assuming that the drive is a pulley, the radius of the pulley is 1CM

The belt output tension is 10KG. If the pulley radius is 2CM, the belt output tension is 5KG, and so on! Common torque units: 1N.M=10KG.CM=0.1KG.M

FAQ

1. For the same power, some speed-regulating motors have greater force and some have less force. Does the greater force mean better quality?

Answer: As long as the speed-regulating motor reaches the rated power, it is not a quality problem. As for the force, it is normal to have a slight difference due to the number of turns of the coil:

Customers who often use speed-regulating motors know that motors are generally not very bad. The main wearing parts are the reduction box, so the quality is affected by the material selection, heat treatment, and processing technology of the gear surface, as well as the fit between the gears;

Our products are checked from all aspects, follow strict technical requirements, and are equipped with imported CNC machining centers. We adhere to the concept of focusing on quality and give back to the society.

2. Why does the motor burn out? Is there a quality problem?

Answer: As mentioned in question 1, the technical requirements for the motor are not very high, and the quality is easy to guarantee. The common cause of burning out is that the speed of the speed regulator is adjusted too low. The principle of the speed-regulating motor is to lower the voltage to adjust the speed. At the same time, the speed of the fan will also decrease, but the power is conserved. At this time, the current will increase, and the temperature will easily rise, leading to damage. Therefore, it is recommended to control the speed range within 70%-100%. When the load is very small, the minimum speed range cannot be lower than 50%.

3. How to choose the model for the first time?

Answer: First determine the torque value, and then determine the required speed. The product of torque and speed is the power; after selecting the power, refer to the selection table to find the required speed and torque, which corresponds to the reduction ratio. At this time, the corresponding speed is the maximum speed, and the speed can be reduced through the speed regulator. Of course, while decelerating, the torque will also be reduced proportionally.

Contact sales:

XINDA

XINDA