How is the axial force of a three-phase AC motor formed?

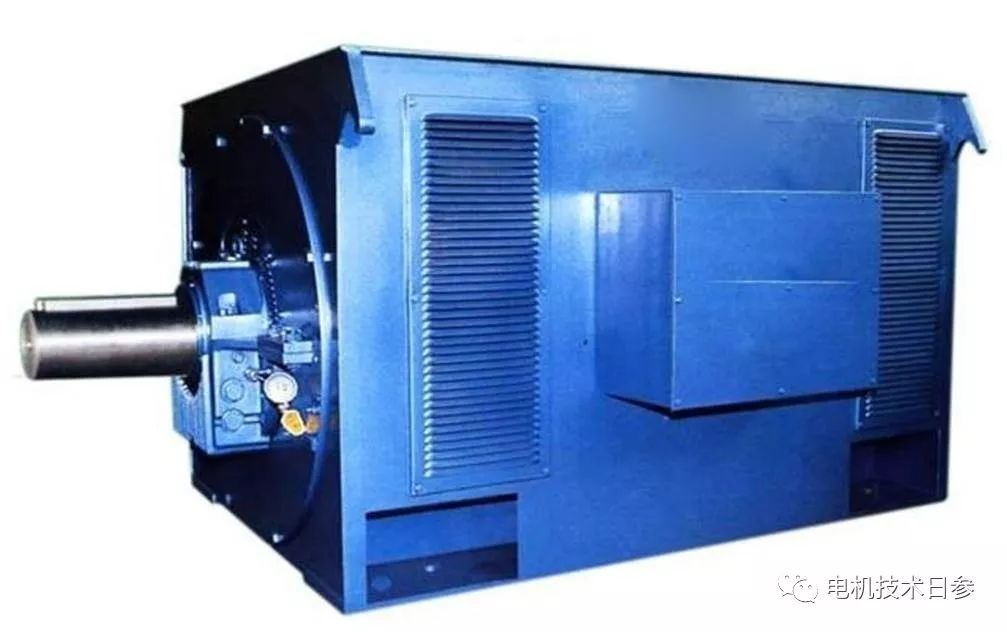

Whether it is a high-voltage or low-voltage motor, customers often report shaft drift problems or bearing temperature rise problems due to axial force. The best working state of a motor is to ensure an ideal relationship between the motor and the load without axial force; in fact, different motors have an axial force to a greater or lesser extent.

For a three-phase AC motor, when the stator winding is connected to the power supply, a rotating magnetic field is generated, thereby generating an induced current in the rotor due to electromagnetic induction. The rotor is magnetized, generating electromagnetic attraction and rotating.

After the synchronous motor is excited, it rotates at the synchronous speed; the rotation of the asynchronous motor produces slip. The motor's rotating magnetic field attraction is generated because the magnetic lines of force have the shortest characteristic. The electromagnetic force makes the motor run on the electromagnetic center line, that is, the electromagnetic forces of the motor stator and rotor act in the radial direction, making them balanced with each other, and no axial magnetic force is generated. However, in actual operation, axial force will be generated due to the following factors.

Causes of axial force

●The axial force generated by the flow of cooling air from the motor rotor fan when it is running at no load.

●Due to factors such as manufacturing process and motor assembly errors, the mechanical center line of the stator and rotor is offset from the electromagnetic center line of the motor, generating axial force.

●In order to reduce the influence of tooth harmonics in the design, the stator or rotor is made into a skewed slot structure. Therefore, when the load is running, the electromagnetic force forces the rotor to deviate to one end and generates axial force.

●The electromagnetic centerline of the motor is the reference line for the motor shaft to dock with the driven mechanical equipment coupling. However, since there is no electromagnetic centerline mark in the design and manufacture of the motor, the installation of the motor and the coupling docking are based on the installation drawings provided in the accompanying documents. The calibration size is based on the designed mechanical center. In this way, the motor will inevitably be offset in actual operation due to the misalignment of the mechanical centerline and the electromagnetic centerline, that is, the error in the installation of the motor and the docking of the coupling, resulting in axial force. The direction of the axial force is a push or pull axial force for the driven mechanical equipment, which causes damage to the bearings or the entire machine of the motor and the driven mechanical equipment.

For increased safety brushless excitation synchronous motors, there are more factors. So from the perspective of process manufacturing and processing, improving the quality of punching sheets; reducing punching burrs; strictly observing the process disciplines of the number of stacking sheets and stacking pressure to ensure the length of the stator and rotor cores; eliminating human installation and assembly errors. At the same time, requiring the company's technical workers to have high technical quality and sophisticated assembly skills is the process guarantee for reducing axial force.

In addition, the designer must be proficient in the manufacturing process and product assembly process, and comprehensively consider the magnitude and direction of the axial force generated by the inherent factors such as the direction of the motor, the fan layout, the direction of the chute, etc. in the structural design, so that they can offset each other or be reduced to the minimum. At the same time, the product assembly technicians must participate in the initial debugging experiment after the product is assembled.

In the debugging experiment, it is more important to require the inspection technicians to accurately require the displacement value and displacement direction of the rotor position in the assembly process in the technical documents according to the actual offset data of the motor center line and the electromagnetic center actually tested in the no-load and load tests during the prototype trial assembly experiment.

XINDA

XINDA