![]()

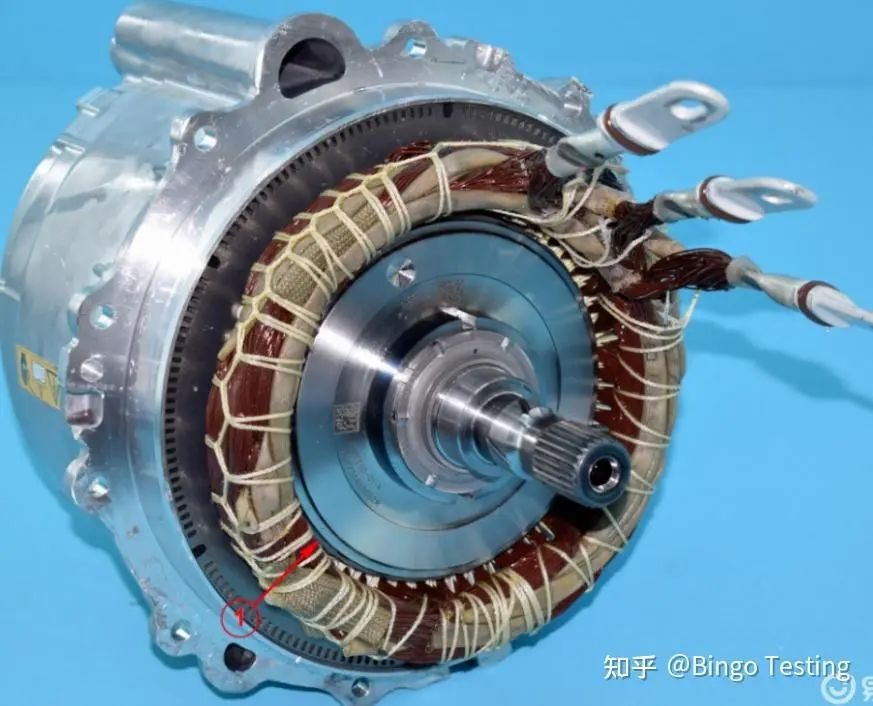

1. Motor insulation resistance

The insulation resistance of the motor stator winding to the housing. The cold insulation resistance value of the motor stator winding to the housing should be greater than 20 MΩ.

2. Motor controller insulation resistance requirements

"GB/T 18488.1-2015 Electric Vehicle Drive Motor System Part 1: Technical Conditions" 5.2.7.3 Drive Motor Controller Insulation Resistance Chapter stipulates:

The cold and hot insulation resistance between the drive motor controller power terminal and the housing, the signal terminal and the housing, and the power terminal and the signal terminal should not be less than 1MΩ.

3.What is cold and hot insulation resistance?

The insulation performance of materials at different temperatures is different. In high temperature environments, the insulation performance of electrical materials will be greatly affected because high temperature will cause changes in the molecular structure of the material, thereby affecting the electrical properties of the material. Generally, the insulation performance is better at low temperatures, and the insulation performance deteriorates at high temperatures. The insulation performance measured at room temperature is the cold insulation resistance, and the insulation performance measured at high temperatures is the hot insulation resistance.

Cold insulation resistance refers to the temperature difference between the product's internal temperature (such as motor windings, internal capacitors of electronic control, etc.) and the ambient air temperature when the insulation resistance is measured in a cold state. The cold state generally refers to the standby state of the motor controller, motor, and generator, when the temperature inside the product is basically the same as the ambient air temperature.

The hot insulation resistance value measured immediately after the motor stops is the lowest insulation resistance value of the motor (the internal temperature of the product reaches the highest). This resistance value is almost unaffected by the ambient temperature, so it can be used to determine the true insulation resistance of the motor, motor controller, etc. The insulation resistance value measured in the cold state is affected by the ambient temperature. The insulation resistance values measured at different ambient temperatures are different, so it is difficult to use it as a basis for determining the true insulation resistance of the motor. When measuring the cold insulation resistance value, the temperature is generally in the range of 10-30℃. Such a wide temperature range corresponds to a relatively wide range of insulation resistance. Generally, the cold insulation resistance of the motor controller at 25℃ and RH60% can reach more than 300MΩ. The hot insulation resistance can be measured by placing the product in a high temperature box, setting Tmax as the highest temperature that can be reached inside the product, and performing a hot insulation resistance test on the product in the box after sufficient heat penetration for T time . At this time, the insulation resistance value tested is the lowest insulation resistance value of the product, and it can also reflect the insulation resistance value when the product is actually running on the vehicle.

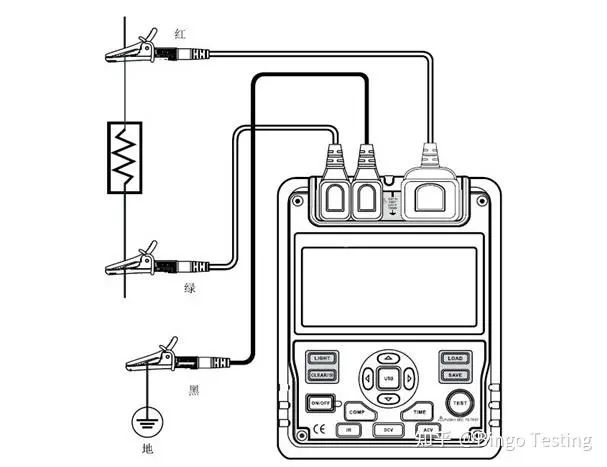

4. How to measure insulation resistance?

A common method is to use an insulation withstand voltage tester, set it to insulation resistance test mode, set the voltage to DC 500V, rise time 60s, duration 60s, monitor the insulation resistance value, and the resistance value tested after stabilization is the insulation resistance.

Generally, the requirements for motor controllers are hot insulation resistance>1MΩ, and cold insulation resistance>20MΩ.

5. What factors cause such a large difference in insulation resistance?

The insulation resistance of all media decreases with increasing temperature.

For motor controllers, the insulation resistance measurement terminals are mainly high voltage to shell, and the insulation between high voltage and shell mainly relies on insulating columns and safety Y capacitors, of which the safety capacitor has the greatest impact. Because the capacitance is proportional to the leakage current, and the resistance of the capacitor is inversely proportional to the capacitance, that is, the higher the capacitance, the lower the insulation resistance. The larger the insulation resistance, the smaller the leakage current under DC voltage .

Generally speaking, the larger the insulation resistance value, the higher the accuracy of the circuit.

6. What are the hazards of low insulation resistance?

In new energy vehicles, the operating voltages of motors and motor controllers are relatively high, reaching DC 750V, and some can reach DC 1200V or above. Due to the inductive characteristics of the motor load, the instantaneous voltage may be as high as 2000V or above. If the insulation resistance of the motor controller or the motor is lower than the specified value, leakage may occur, which may cause safety accidents. Therefore, insulation resistance is one of the mandatory inspection items for electronic control products.

At present, all new energy vehicles are equipped with high-voltage insulation resistance testers, which will monitor the insulation resistance of the high voltage to the frame in real time. When the insulation resistance is too low, an alarm will be issued, and the motor may even be refused to operate, reminding maintenance.

7. Summary

Insulation resistance is divided into cold state and hot state insulation resistance. This is a naming method. In fact, there is no clear specified value for cold state and hot state. Generally, hot state insulation resistance refers to the insulation resistance value measured immediately when the vehicle stops after running for a period of time. At this time, the insulation resistance value is relatively small and closer to the resistance value during actual working.

Therefore, when measuring the insulation resistance before the product is offline, it is best to conduct a hot insulation resistance test immediately after the product is undergoing an aging test, or after high-temperature aging. At this time, the measured resistance value can better reflect the true insulation characteristics of the product.

XINDA

XINDA