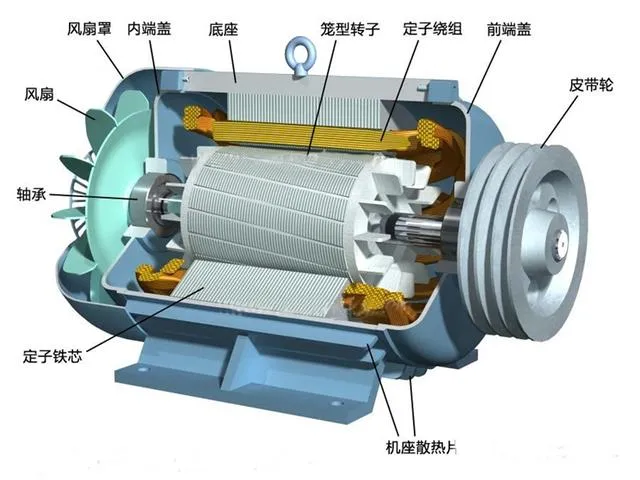

![]() Traditionally, there are two directions in motor design: copper motor and iron motor. Copper motor uses electric field as the main source of motor torque, which involves the current (I) and the number of enameled coils (N) in the motor torque formula. Therefore, the design of copper motor usually requires more enameled wire, which has become the current mainstream design trend. In contrast, iron motor uses a larger silicon steel sheet area and less enameled wire, and uses spatial dimensions to obtain motor torque. However, due to the large size of iron motors and the low energy density per unit area, they are not popular in the market.

Traditionally, there are two directions in motor design: copper motor and iron motor. Copper motor uses electric field as the main source of motor torque, which involves the current (I) and the number of enameled coils (N) in the motor torque formula. Therefore, the design of copper motor usually requires more enameled wire, which has become the current mainstream design trend. In contrast, iron motor uses a larger silicon steel sheet area and less enameled wire, and uses spatial dimensions to obtain motor torque. However, due to the large size of iron motors and the low energy density per unit area, they are not popular in the market.

1. Copper motor and iron motor

It is not difficult to judge that the copper loss ratio of copper motors is higher, while the iron loss ratio of iron motors is higher. If we look up the commonly used magnetic conductive material "silicon steel sheet" for motors, we will find that the iron loss is indicated in W/KG, which shows that the iron loss is related to the weight of the silicon steel sheet. Therefore, the iron motor uses a larger silicon steel sheet size, which also means that the weight of the silicon steel sheet is heavier, so the iron loss is greater.

2. Replace with larger silicon steel

To reduce iron loss, the general method is to replace the silicon steel sheet; but for motor designers, the first task is to confirm the magnetic field state inside the silicon steel sheet. In the iron loss equation, we can see various forms of energy loss and find corresponding solutions. However, there is a hidden loss that cannot be ignored, which is "magnetic leakage". This magnetic leakage phenomenon will cause the motor torque to decrease and may even cause electromagnetic wave interference. There are two solutions to this magnetic leakage phenomenon. The simplest one is to replace a larger silicon steel sheet, so that the contact area with the magnetic lines is larger and the magnetic leakage is reduced.

3. Optimize magnetic lines

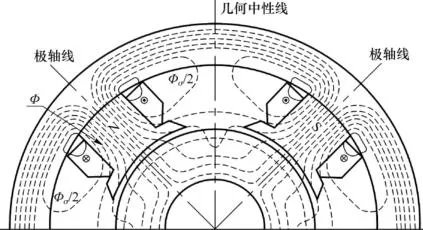

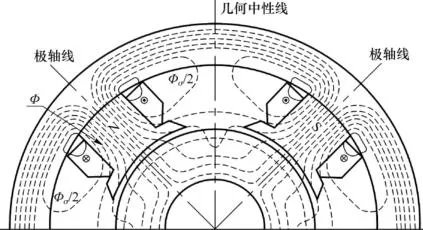

In addition to replacing silicon steel sheets, magnetic flux leakage can also be avoided by optimizing magnetic flux lines. Looking at the figure below, we can see that a few magnetic flux lines deviate from the normal path, which is what we generally call magnetic flux leakage. This phenomenon may cause the motor's torque to drop and may even generate electromagnetic interference.

When the magnetic flux carrying capacity of silicon steel sheets is not enough to bear too much magnetic force, it may lead to magnetic leakage. For this reason, we can of course increase the size of silicon steel sheets so that they can carry more magnetic force. However, the magnetic induction strength of silicon steel sheets is limited, which is the bottleneck encountered in recent motor design. As the magnetic force of magnets continues to increase, designers can easily choose magnets with high magnetic force. However, there is no option to increase the carrying capacity of silicon steel sheets.

At the same time, the theory of magnetic resistance tells us that magnetic lines of force always tend to choose the path that is easiest to pass through. Therefore, when the magnetic lines of force find a better path than the path planned by the designer, it will change direction. For example, in the figure, you can see that some magnetic lines of force cross the slot instead of going around the yoke, just like when running on the playground, we will choose to cross the grass in the middle instead of walking a big circle. Although this kind of leakage flux is sometimes unavoidable, as motor designers, we should optimize the magnetic lines of force by adjusting the motor magnetic field and strive to reduce the occurrence of leakage flux.

Therefore, in addition to directly reducing iron losses, we can also improve the efficiency of the motor by properly planning the energy path inside the magnetic field.

The use of magnetic energy must comply with the principle of minimum effort. Silicon steel sheets should make use of magnetic lines of force as much as possible to avoid magnetic leakage.

XINDA

XINDA