Reasons for high current in high-efficiency motors and analysis of motor power consumption

After replacing with a high-efficiency motor, the current will be too high during the total operation. Therefore, all motors need to be replaced, and the power consumption will also increase. This article will analyze the reasons for the high current of high-efficiency motors and the power consumption of the motors, and compare the power consumption of the motors with the actual operating current values to obtain the current component of the motors.

Keywords: high efficiency motor; no-load current; load current

introduction

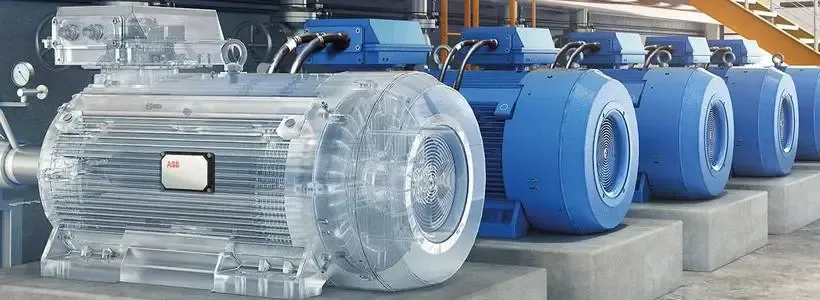

1. High-efficiency motor design

High-efficiency energy-saving motors are motors with high efficiency added to traditional motors. High-efficiency motors use new processes and materials, which reduce the consumption of mechanical energy, electromagnetic energy and thermal energy, and improve the efficiency of actual output. Compared with ordinary motors, the use of high-efficiency motors is more significant in energy saving, and the efficiency can generally be increased to 4%. In the actual conversion process of electric energy by the motor, mechanical energy will be generated, and part of the energy will be lost. There are five aspects of motor loss, including stator loss, stray loss, rotor loss, wind friction loss, and iron loss. Compared with ordinary motors, university motors have made great adjustments in design, mainly to reduce these five losses and greatly improve the actual efficiency of the motor. The following is a specific analysis.

1.1 Stator losses

The stator is composed of two aspects, including the stator core and the stator coil. The stator core is a key component in the magnetic flux circuit of the motor. Compared with ordinary motors, high-efficiency motors use silicon steel sheets with good magnetic conductivity, which greatly reduces the thickness of the silicon steel sheets. For this reason, the stator core made of cold-rolled silicon steel sheets has very little induced current loss. In the design and manufacturing process of the stator coil, the wire used in the high-efficiency motor is a relatively thick wire with better insulation, which also increases the stator slots. At the same time, the length of the stator winding end is greatly reduced, so that the end loss can be reduced.

1.2 Rotor losses

The principle of rotor loss is the same as that of stator loss. Therefore, high-efficiency motors need to minimize rotor loss.

1.3 Iron loss

High-efficiency motors greatly reduce iron losses by adopting the following methods: 1. Using cold-rolled silicon steel sheets with relatively good magnetic permeability; 2. The length of the iron core greatly reduces the density of the magnetic flux; 3. Using iron core sheets with good effects.

1.4 Stray losses

There are several types of stray losses in high-efficiency motors: 1. The length of the air gap needs to be increased; 2. The end length of the coil needs to be reduced; 3. The surface insulation of the rotor slots needs to be strengthened; 4. The harmonics of the rotor slots need to be reduced during design.

1.5 Wind wear

There are two main ways to reduce wind wear in high-efficiency motors: 1. Reduce the friction between high-efficiency bearings and lubricants; 2. Use small fan blades to reduce wind resistance losses.

2 Motor running current analysis

In order to analyze the running current of the motor, it is necessary to analyze and compare the actual running current of the ordinary motor and the high-efficiency motor.

2.1 No-load current

The no-load current of the motor is mainly determined by the density of the magnetic flux and the length of the air gap between the stator and the rotor. If the magnetic flux density is low, the length of the air gap will become smaller and the no-load current of the motor will become less.

Normally, the air gap length of the motor is relatively small, usually a few millimeters. Therefore, the main magnetic flux will pass through the loop, and the air gap length will be small at this time, which is one percent of the length of the entire magnetic loop. Because the magnetic permeability of silicon steel sheets is greater than the magnetic permeability of air, for this reason, for the motor no-load current, the density of the magnetic flux affects the length of the air gap.

2.1.1 Magnetic flux density

High-efficiency motors need to increase the length of the core, and at this time the magnetic permeability performance requires the selection of cold-rolled silicon steel sheets. For this reason, the magnetic flux density of the high-efficiency motor will become smaller, and compared with the no-load current of ordinary motors, the no-load current of the high-efficiency motor will become smaller.

2.1.2 Air gap length

For small-power motor specifications, stray losses will seriously affect the actual efficiency of the motor. Therefore, during the design process of high-efficiency motors, it is necessary to control the length of the air gap. Since the motor parameters are caused by the air gap, when compared with small-power motors, the actual effect of the air gap length on the no-load current can be ignored.

For high-power motors, the efficiency of the motor will be affected by the additional loss. Therefore, in the design of high-efficiency motors, the length of the air gap needs to be larger than that of ordinary motors. For high-power motors, the air gap length of high-efficiency motors increases. Compared with ordinary motors, the no-load current of high-efficiency motors will increase and the power will be very low.

2.1.3 Comprehensive analysis

For small-power motors, the air gap is usually not long enough, which reduces the density of the magnetic flux. Therefore, compared with the no-load current of ordinary motors, the actual no-load current of high-efficiency motors is very small.

For high-power motors, although the magnetic flux density of high-efficiency motors has obvious changes, the air gap length of high-efficiency motors will become larger, causing the magnetic flux density to affect the air gap length. At this time, the no-load current of the high-efficiency motor will increase.

2.2 Load current

The calculation formula of the motor's output shaft power is:

In view of different working conditions, such as voltage, temperature and output power, in the actual running motor, the voltage and output shaft power are constants, so K is also a constant.

Under the same working conditions, when comparing the current of a high-power motor with that of an ordinary motor, the operating current of a high-efficiency motor is determined by the difference between the motor's excitation current and its efficiency.

The efficiency difference between high-power motors and ordinary motors is analyzed and compared. The value of high-efficiency motors is very small, so under the same working conditions, compared with the current value of ordinary motors, the active current of high-efficiency motors is very small, but it does not change. Therefore, in the actual operation of high-efficiency motors, the change of current is determined by the change of excitation current, but it is only the current in operation.

3 Analysis of motor power consumption

The power consumption of the motor is the sum of the shaft power output by the motor and the actual loss. The test was taken on the same belt, both were no-load operation, and the operating voltage was the same. Therefore, the actual operating conditions of the two motors were the same, and the output shaft power was also the same. Combined with the above calculation method, the power consumption of ordinary motors and high-efficiency motors can be accurately calculated.

3.1 The theoretical calculation of the power consumption ratio between high-efficiency motors and ordinary motors is as follows:

Motor output shaft power calculation formula:

3.3 Comparative Analysis

Through the above calculations, it can be analyzed that compared with the power consumption of ordinary motors, the power consumption of high-efficiency motors is 97.15%, and the actual data measured is 96.05%. Analyzing the two sets of data, it can be concluded that the power consumption of high-efficiency motors is the smallest under load, but there is still a certain error in the actual measurement. The reason for the error is that after ordinary motors have been used for a long time, the loss of the motor will decrease.

Conclusion

According to the analysis of the actual power consumption of the motor, it can be concluded that the change of the parameters of the two motors in the design will cause the change of the ordinary motor and the high-efficiency motor. By comparing, it can be analyzed that there is no relationship between the ratio of the actual operating current and the power consumption of the motor. The main thing is the active current component of the motor. According to the analysis of the motor current, the actual operating current of the high-efficiency motor is often greater than that of the ordinary motor. Compared with the ordinary motor, the active current of the high-efficiency motor is significantly lower. Under the same working conditions, the power consumption of the ordinary motor and the high-efficiency motor is significantly lower.

XINDA

XINDA