What are the types of asynchronous motors?

AC asynchronous motor

AC asynchronous motors are electric motors that run on leading AC voltage and are widely used in household appliances such as electric fans, refrigerators, washing machines, air conditioners, hair dryers, vacuum cleaners, range hoods, dishwashers, electric sewing machines, food processors, and various power tools and small electromechanical equipment.

AC asynchronous motors are divided into induction motors and AC commutator motors. Induction motors are further divided into single-phase asynchronous motors, AC/DC dual-purpose motors and repulsion motors.

The speed of the motor (rotor speed) is less than the speed of the rotating magnetic field, so it is called an asynchronous motor. It is basically the same as an induction motor. s=(ns-n)/ns. s is the slip rate,

ns is the magnetic field speed and n is the rotor speed.

Fundamental

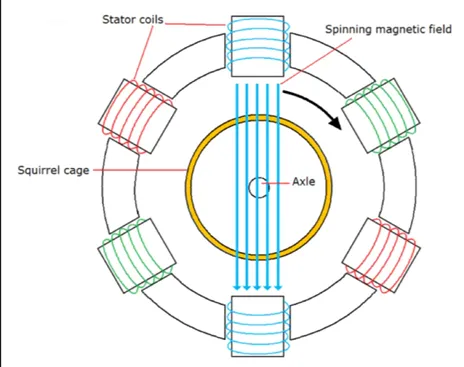

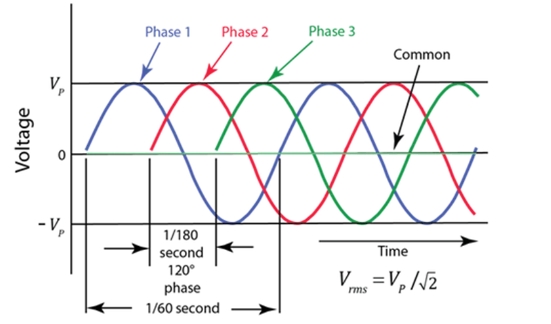

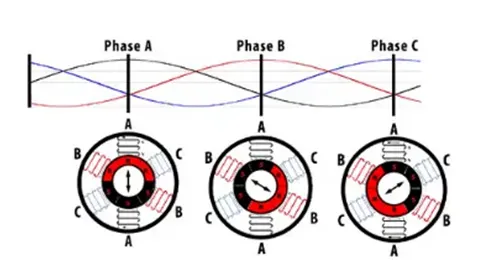

1. When the three-phase asynchronous motor is connected to a three-phase AC power supply, a three-phase symmetrical current flows through the three-phase stator winding to generate a three-phase magnetomotive force (stator rotating magnetomotive force) and a rotating magnetic field.

2. The rotating magnetic field and the rotor conductor have a relative cutting motion. According to the principle of electromagnetic induction, the rotor conductor generates an induced electromotive force and an induced current.

3. According to the law of electromagnetic force, the current-carrying rotor conductor is acted upon by electromagnetic force in the magnetic field, forming an electromagnetic torque that drives the rotor to rotate. When the motor shaft carries a mechanical load, mechanical energy is output to the outside.

An asynchronous motor is an AC motor whose speed under load is not constant relative to the frequency of the connected power grid. It also changes with the size of the load. The greater the load torque, the lower the rotor speed. Asynchronous motors include induction motors, double-fed asynchronous motors, and AC commutator motors. Induction motors are the most widely used, and can generally be called asynchronous motors without causing misunderstanding or confusion.

The stator winding of the ordinary asynchronous motor is connected to the AC power grid, and the rotor winding does not need to be connected to other power sources. Therefore, it has the advantages of simple structure, easy manufacturing, use and maintenance, reliable operation, small mass and low cost. The asynchronous motor has high operating efficiency and good working characteristics. It runs at a near constant speed from no-load to full load, and can meet the transmission requirements of most industrial and agricultural production machinery. The asynchronous motor is also easy to generate various protection types to meet the needs of different environmental conditions. When the asynchronous motor is running, it must absorb reactive excitation power from the power grid, which makes the power factor of the power grid worse. Therefore, synchronous motors are often used to drive high-power, low-speed mechanical equipment such as ball mills and compressors. Since the speed of the asynchronous motor has a certain slip relationship with the speed of its rotating magnetic field, its speed regulation performance is poor (except for AC commutator motors). For transportation machinery, rolling mills, large machine tools, printing and dyeing and papermaking machinery that require a wider and smoother speed regulation range, it is more economical and convenient to use DC motors. However, with the development of high-power electronic devices and AC speed control systems, the speed regulation performance and economy of asynchronous motors suitable for wide speed regulation are comparable to those of DC motors.

Single-phase asynchronous motor

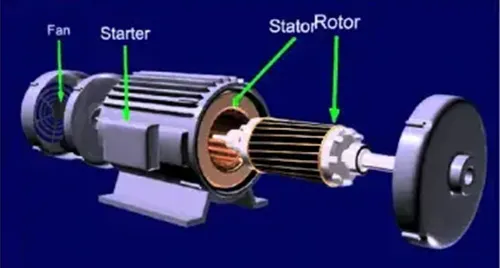

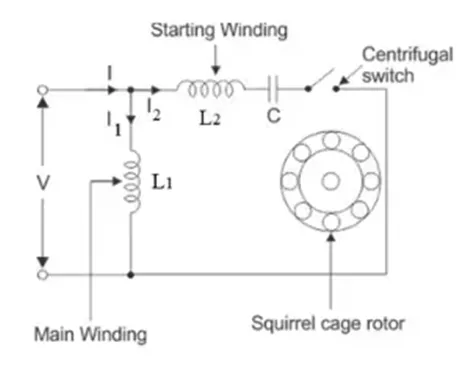

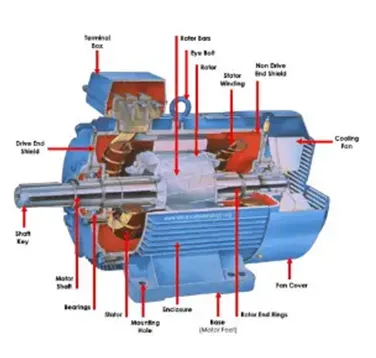

A single-phase asynchronous motor consists of a stator, a rotor, bearings, a casing, an end cover, etc.

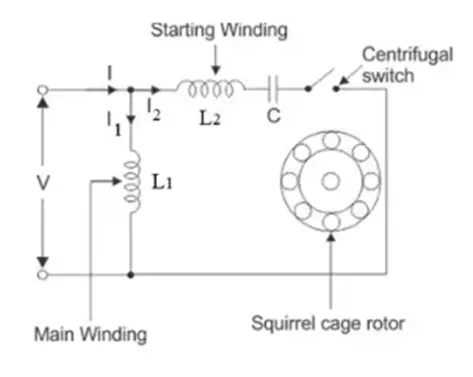

The stator consists of a frame and an iron core with windings. The iron core is made of silicon steel sheets punched and stacked, and two sets of main windings (also called running windings) and auxiliary windings (also called starting windings and secondary windings) separated by 90° electrical angle are embedded in the slots. The main winding is connected to the AC power supply, and the auxiliary winding is connected in series with the centrifugal switch S or the starting capacitor, running capacitor, etc., and then connected to the power supply.

The rotor is a cage-type cast aluminum rotor, which is made by laminating the cores and then casting aluminum into the core slots, and casting end rings together to short-circuit the rotor bars into a squirrel cage shape.

Single-phase asynchronous motors are further divided into single-phase resistance-start asynchronous motors, single-phase capacitor-start asynchronous motors, single-phase capacitor-run asynchronous motors and single-phase dual-value capacitor asynchronous motors.

Three-phase asynchronous motor

The structure of the three-phase asynchronous motor is similar to that of the single-phase asynchronous motor. The three-phase winding is embedded in the stator core slot (there are three structures: single-layer chain type, single-layer concentric type and single-layer cross type). After the stator winding is connected to the three-phase AC power supply, the rotating magnetic field generated by the winding current generates an induced current in the rotor conductor. Under the interaction of the induced current and the rotating magnetic field of the air gap, the rotor generates an electromagnetic rotor (i.e., an asynchronous rotor) to rotate the motor.

Shaded pole motor

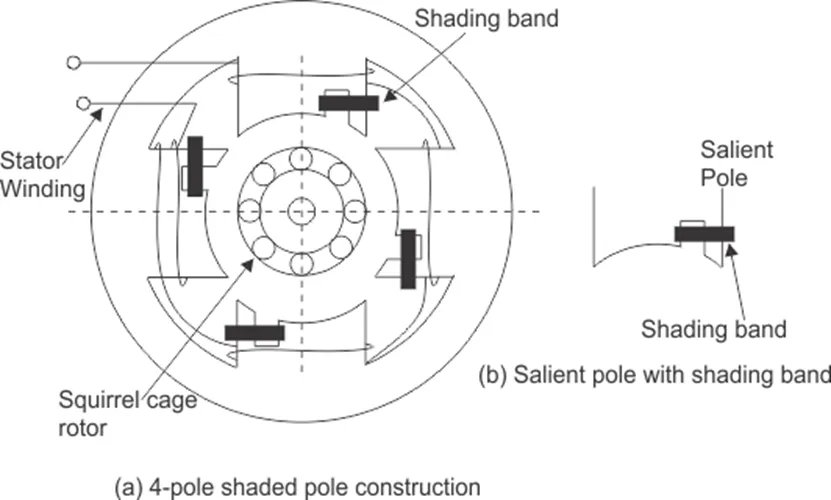

The shaded pole motor is the simplest type of unidirectional AC motor, usually using a cage-type skewed slot cast aluminum rotor. It is divided into salient pole shaded pole motor and hidden pole shaded pole motor according to the different stator shape and structure.

The stator core of the salient pole shaded pole motor is a square, rectangular or circular magnetic field frame with protruding magnetic poles. Each magnetic pole has one or more auxiliary short-circuit copper rings, namely shaded pole windings. The concentrated winding on the salient pole is used as the main winding.

The stator core of the hidden pole shaded pole motor is the same as that of the ordinary single-phase motor. Its stator winding adopts distributed winding. The main winding is distributed in the stator slot. The shaded pole winding does not use a short-circuit copper ring, but is wound with thicker enameled wire to form a distributed winding (self-short-circuited after series connection) and embedded in the stator slot (about 2/3 of the total number of slots), playing the role of an auxiliary group. The main winding and the shaded pole winding are separated by a certain angle in space.

When the main winding of the shaded-pole motor is energized, the shaded-pole winding will also generate an induced current, causing the magnetic flux of the stator pole covered by the shaded-pole winding and the uncovered part to rotate toward the covered part.

Single-phase series motor

The stator of a single-phase series-excited motor consists of a salient pole core and an excitation winding, and the rotor consists of a non-salient pole core, an armature winding, a commutator, and a rotating shaft. A series circuit is formed between the excitation winding and the armature winding through brushes and a commutator.

The single-phase series-excited motor is an AC/DC dual-purpose motor. It can work using both AC and DC power supplies.

XINDA

XINDA