Comprehensive analysis of reduction motor types and selection

I. Overview

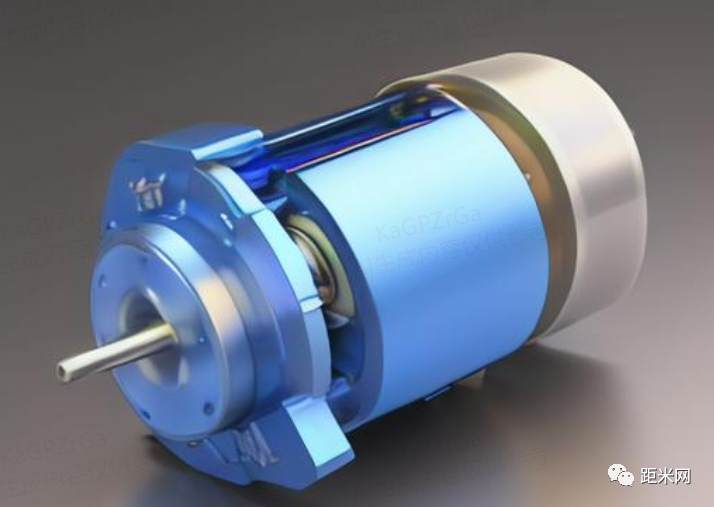

A geared motor, as the name suggests, is a mechanical device that combines a high-speed rotating motor with a reducer. It reduces the speed of the motor to increase the output torque to meet the power needs in various industrial applications. There are many types of geared motors, and many factors need to be considered during the selection process. This article will provide a comprehensive analysis of the types and selection of geared motors to help you make informed decisions when purchasing.

2. Types of reduction motors

-

Gear reduction motor

Gear reduction motor is a common reduction motor that transmits torque through gear meshing and has the characteristics of high transmission efficiency, high precision, and high rigidity. Depending on the use environment, gear reduction motors can be divided into two types: closed and open. The enclosed reduction motor has the advantages of high protection level and wide application range, but the price is relatively high. Open geared motors are cheaper but require additional protective devices.

-

Planetary reduction motor

Planetary reduction motor is a reduction motor with the characteristics of high reduction ratio, small size and light weight. It uses a planetary gear structure to achieve deceleration, with high transmission efficiency and smooth output characteristics. Planetary reduction motors are suitable for high-precision transmission systems that have strict requirements on volume and weight.

-

Harmonic reduction motor

Harmonic reduction motor is a motor that uses the principle of harmonics to achieve deceleration. It is flexible and can adapt to large changes in installation dimensions. Harmonic reduction motors are suitable for applications that require larger installation space and higher transmission accuracy, such as robots, robotic arms, etc.

-

Worm gear motor

The worm gear reduction motor is a reduction motor using a worm gear structure. It has the characteristics of large transmission ratio, compact structure and smooth transmission. Worm gear reduction motors are suitable for occasions with high transmission ratio requirements and large space restrictions, such as elevators, cranes, etc.

3. Selection of reduction motor

-

Understand application scenarios

When selecting a geared motor, you must first understand the application scenario, including the type of transmission system, load characteristics, speed range, installation space and other factors. These factors will directly affect the selection and configuration of the reduction motor.

-

Determine the reduction ratio

The reduction ratio is one of the important parameters of the reduction motor, which determines the deceleration ability of the reduction motor. According to the requirements of the application scenario, determine the appropriate reduction ratio range to ensure the stability and reliability of the transmission system.

-

Consider transmission efficiency

Transmission efficiency is one of the important indicators to measure the performance of the reduction motor. When selecting a reduction motor, attention should be paid to its transmission efficiency to ensure that the energy consumption and heat generation of the entire transmission system are controlled within a reasonable range.

-

Focus on rigidity and precision

Rigidity and accuracy are another important indicator of the performance of the geared motor. High rigidity can ensure the stability and load-bearing capacity of the transmission system, while high precision can ensure the smooth movement and position control accuracy of the output shaft. Depending on the application needs, select a geared motor with appropriate rigidity and accuracy.

-

Consider maintenance and reliability

When selecting a geared motor, attention should be paid to its maintenance and reliability. Choosing a geared motor with long life and low maintenance costs can reduce the operating costs of the entire transmission system. In addition, attention should also be paid to its protection level and use environment adaptability to ensure that the reduction motor can work normally under harsh conditions.

-

Consider cost factors

When selecting a geared motor, cost factors should also be considered. Comprehensively consider the initial purchase cost, operating cost, maintenance cost and other factors to select the most cost-effective reduction motor solution. At the same time, according to actual needs, customized reduction motors can be selected to meet the requirements of special application scenarios.

XINDA

XINDA