![]()

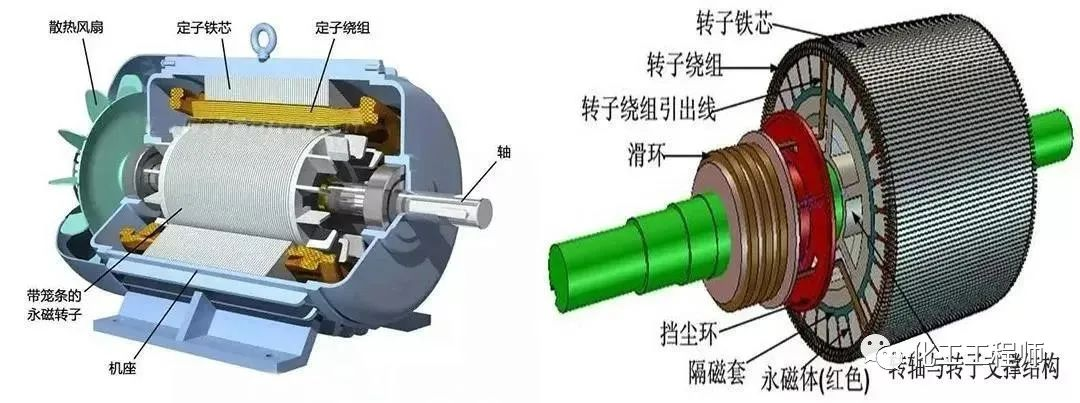

The permanent magnet motor uses permanent magnets to generate the magnetic field of the motor. It does not require an excitation coil or an excitation current. It has high efficiency and a simple structure. It is a good energy-saving motor. With the advent of high-performance permanent magnet materials and the rapid development of control technology, permanent magnet motors applications become more widespread.

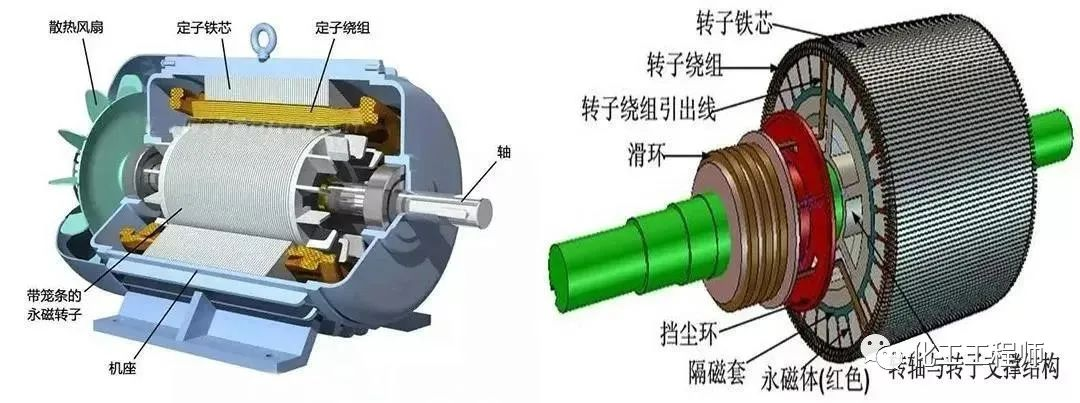

1. Different properties of the magnetic field: The rotor structure of the permanent magnet motor is different from that of the ordinary motor. The permanent magnet motor rotor is equipped with permanent magnet poles; the ordinary motor rotor is equipped with an excitation coil, which requires the passage of current to create a magnetic field.

2. Power density: Compared with ordinary motors, permanent magnet motors have high power density, which mainly means that permanent magnet motors are small in size but have large power generation or output. .

3. More energy-saving: Compared with traditional motors, it saves electric energy at any speed point, especially when the speed is low. This advantage is particularly obvious. Compared with ordinary motors, the energy saving reaches 20%-40%. Most modern submarines use large-diameter, low-speed, 7-blade large-inclination propellers or pump-jet propellers, which have low rotational speed and high propulsion efficiency. Moreover, submarines mostly maneuver at low-noise speeds underwater, which makes this advantage of permanent magnet motors better reflected and brought into play.4. Small size and light weight: The permanent magnet motor has a simple structure. Due to the use of high-performance permanent magnet materials to provide a magnetic field, the air gap magnetic field of the permanent magnet motor is greatly enhanced compared with ordinary motors, while the permanent magnet motor is smaller in size and weight. Ordinary motors are greatly reduced, and the size and shape of the motor are also flexible and diverse.5. Lower failure rate and wider use: Due to the use of high-performance rare earth permanent magnet materials to provide the magnetic field, the failure rate is lower and it is more widely used.6. Large starting torque: Since the rotor winding does not work when the permanent magnet motor is working normally, the rotor winding can be designed to fully meet the requirements of high starting torque, for example, from 1.8 times to 2.5 times, or even greater.

XINDA

XINDA