The reason why AC asynchronous motor is less efficient than permanent magnet synchronous motor

AC asynchronous motors and permanent magnet synchronous motors are two common motor types in modern industrial applications. They have certain differences in structure and working principles. Although permanent magnet synchronous motors are relatively more efficient, asynchronous motors still have their unique advantages and applicable scenarios.

First, we need to understand the working principles and structural characteristics of AC asynchronous motors and permanent magnet synchronous motors.

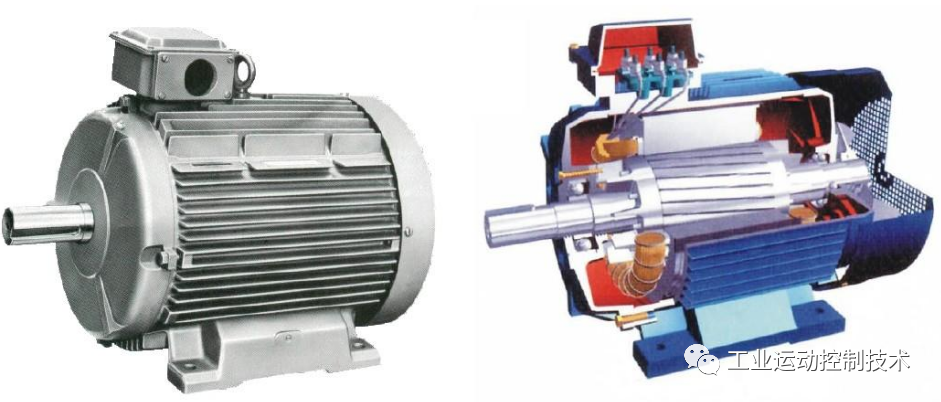

AC asynchronous motors are motors that work on the principle of electromagnetic induction. Their rotors do not have any permanent magnets or a directly connected power supply. It generates a rotating magnetic field on the stator by alternating current input through the power supply, and the rotor of the asynchronous motor rotates by interacting with the rotating magnetic field. Common AC asynchronous motors include induction motors and induction generators.

A permanent magnet synchronous motor is a motor that operates by utilizing the magnetic field generated by permanent magnets on the rotor to interact with the rotating magnetic field on the stator. Since the permanent magnet synchronous motor has permanent magnets on the rotor, it does not require the input current from the power supply to generate a magnetic field. The operating speed of the permanent magnet synchronous motor is controlled by controlling the frequency and phase of the rotating magnetic field on the stator.

Below we will discuss in detail the reasons why AC asynchronous motors are less efficient than permanent magnet synchronous motors:

1. The magnetic field is generated in different ways:

AC asynchronous motors require current to generate a magnetic field on the stator coil, while permanent magnet synchronous motors generate a magnetic field through permanent magnets. Since the magnetic field in an AC induction motor is generated by current, there will be resistance and electromagnetic induction losses in the current, so there will be additional energy loss. The magnetic field of the permanent magnet synchronous motor comes directly from the permanent magnet, so there is no need to input additional current, so it can reduce energy loss.

2. Different rotor losses:

The rotor in the AC asynchronous motor is an aluminum cage structure, often called a "squirrel cage rotor". Due to the good conductivity of aluminum, the current in the rotor will produce eddy current losses, resulting in energy loss. The permanent magnet synchronous motor has permanent magnets fixed on the rotor, which does not produce eddy current losses and reduces rotor losses.

3. Efficiency difference under rated load:

At rated load, the efficiency of permanent magnet synchronous motors is relatively high due to the way the magnetic field is generated and the low rotor losses. The efficiency of AC asynchronous motors will be relatively low due to the presence of magnetic fields generated by current and rotor losses.

However, despite its relatively low efficiency, AC induction motors are still widely used in many applications. The main reasons are as follows:

1. Strong starting ability:

AC asynchronous motors have good starting capabilities, especially when starting with large loads. Due to the rotor structure of the AC asynchronous motor, when the motor is started, due to the induction effect of the rotor, the motor will automatically reach the rotation speed of the rotor and can start quickly.

2. Long transmission distance:

AC asynchronous motors are suitable for scenarios with long power transmission distances because their power transmission losses are relatively small. Permanent magnet synchronous motors are generally suitable for scenarios with short power transmission distances. When transmitting power over long distances, AC asynchronous motors have higher power transmission efficiency due to cable resistance and electromagnetic induction losses.

3. The cost is relatively low:

Since the AC asynchronous motor has a simple structure and mature manufacturing process, its manufacturing cost is relatively low. In contrast, permanent magnet synchronous motors require the use of permanent magnet materials and have a more complex control system, so the manufacturing cost is higher.

To sum up, the main reasons for the lower efficiency of AC asynchronous motors compared to permanent magnet synchronous motors include different magnetic field generation methods, different rotor losses, and efficiency differences under rated loads. However, AC asynchronous motors still have certain advantages in many scenarios. Different motor types should be selected according to specific application scenarios and work requirements.

XINDA

XINDA