Regarding the magnetic levitation blower, this article explains it clearly

As we all know, if the sewage treatment industry wants to save energy and protect the environment, it generally needs to be carried out from two levels. One is the selection of production processes , and the other is the selection of machinery and equipment .

There is nothing to say about the first one. Most of the sewage plants currently in use in our country use the activated sludge aerobic process. Regarding the second point, I want to talk about fans. In the sewage treatment process, the energy consumed by blast aeration accounts for more than half of the energy consumed by the entire system. Therefore, the selection of fans is particularly important in saving operating costs.

Obviously, traditional blowers can no longer meet the needs of the sewage treatment industry for energy conservation and emission reduction. Our country has also strengthened its research on the application of magnetic levitation blowers in sewage treatment. It has now been put into use in more than 30 provinces, municipalities and autonomous regions across the country , which not only meets the requirements of the times for energy conservation and emission reduction, but also brings great economic benefits to the sewage treatment industry. benefit.

Today, the editor will take water friends to learn more about the magnetic levitation blower. The article is divided into five parts and you can read it as needed.

-

What is a magnetic levitation blower?

-

Main process features of magnetic levitation blower

-

Technical parameters of magnetic levitation blower

-

Technical advantages of magnetic levitation blower

-

Performance comparison with other blowers

01

What is a magnetic levitation blower?

The magnetic levitation blower is also called the magnetic levitation single-stage high-speed centrifugal blower. Its main function in sewage treatment is to aerate the water to increase the oxygen content in the water, thereby removing iron and manganese or promoting the degradation of organic matter by aerobic microorganisms to remove oxidizable and precipitated substances. the goal of.

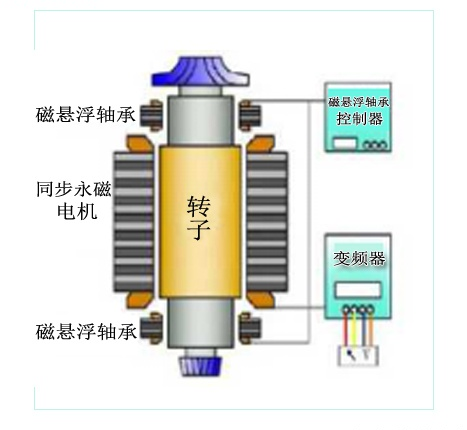

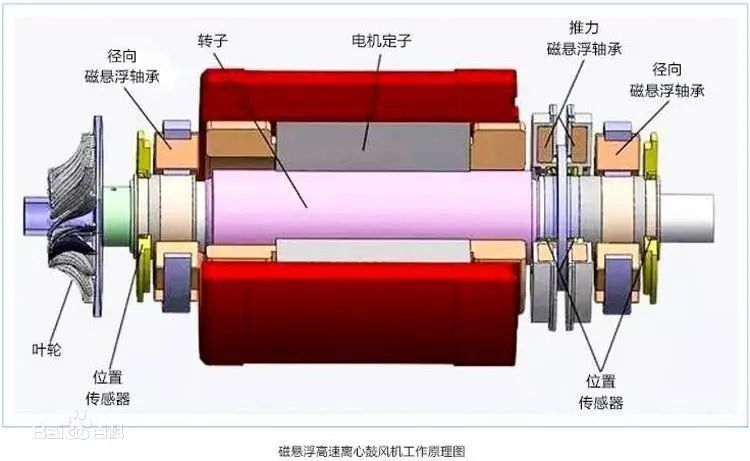

Magnetic levitation blower is a type of turbine equipment using magnetic bearings. Its main structure is that the blower impeller is directly installed on the extended end of the motor shaft, and the rotor is suspended vertically on the active magnetic bearing controller. It does not require a speed increaser and coupling, and is directly driven by a high-speed motor.

The core of the single-stage high-speed centrifugal blower whose speed is adjusted by a frequency converter is magnetic bearing and permanent magnet motor technology . The structure is as shown in the figure.

02

Main process features of magnetic levitation blower

1. High-efficiency impeller: The high-efficiency impeller is designed with three-dimensional flow, and five-axis machining technology ensures the manufacturing accuracy of the impeller.

2. Magnetic bearings: no mechanical wear, low energy, semi-permanent life.

3. Integrated structural design: The fan's imported filter, cooling system, fully automatic anti-surge system, power outage and fault protection system have all achieved unified integrated design, and users do not need to purchase other components separately. The fan impeller is directly installed on the shaft end of the motor, designed to be integrated with the control system, and integrated into the box, with a simple and concise structure.

4. Easy installation and maintenance: The overall structure of the magnetic levitation blower is a box structure. It adopts self-balancing technology and active vibration reduction design, which makes the vibration of the body very small. Therefore, the installation of the equipment does not require an installation foundation, and it can be installed on a general level ground. . After the device is on the ground, the connection management can be turned on and used, which is very convenient.

5. System modular design: According to different user flow rates, multiple blowers are allowed to work in parallel, with a wide adjustment range and strong flexibility.

03

Technical parameters of magnetic levitation blower

At present, my country's magnetic levitation blower series models with independent intellectual property rights have gradually become complete, and the maximum single-machine power has reached 1MW, which fully meets the needs of various large, medium and small sewage treatment plants in my country. The parameters are as follows:

power

-

Covering 50kW to 1WM, the series models are diverse and can meet the needs of different users. It can also realize multi-machine linkage control and multiple devices work together to further improve efficiency.

Air volume

-

Covering 30m3/min to 660m3/min, the air volume is adjustable with variable frequency. The air volume adjustment range of a single device is as high as 50%. The air volume can be adjusted according to water quality, matching and adapting to the precision aeration system that is now respected.

Boost

-

Covering 40kPa to 150kPa, the pressure is adjustable with variable frequency, which can effectively respond to pressure changes caused by changes in water level, achieve rapid response to changes, and meet the needs of process conditions with pressure changes.

high speed motor

-

The high-speed permanent magnet synchronous motor is directly coupled to the impeller to completely eliminate mechanical transmission losses. The speed is as high as 50,000RPM and the efficiency is over 97%.

position sensor

-

The inductive sensor can monitor the X, Y, and Z directions at the same time. The inductive sensor sends an AC signal of 5~100KHz to the sensor probe, monitors the inductance value at different positions, and obtains the position offset.

noise

-

Not higher than 85 decibels, which is within the safe noise range that humans can bear. Since there is no mechanical friction, the noise comes from the high-speed flow of air. It is a high-frequency noise with short propagation distance and is easy to eliminate. It can be effectively reduced by pipe coating. noise.

Picture source from the Internet, infringement and deletion

04

Technical advantages of magnetic levitation blower

Energy saving and efficient

-

Because it uses magnetic suspension bearings, it has no contact, no friction, no need for lubrication, is not easy to cause contact and mechanical losses, and does not require variable speed adjustment. At the same time, the blower can also adjust the speed according to working conditions, saving more electricity for users; most importantly, it can also adjust the speed to achieve changes in pressure and flow according to changes in external factors, which saves energy compared to traditional fans. 30%, the energy saving and emission reduction effect is remarkable.

High cooling efficiency

-

The fan's cooling system uses a combination of air cooling and self-circulating water cooling to achieve optimal cooling efficiency while avoiding damage to the motor caused by motor heating, extending the service life of the motor and improving the stability of the equipment. .

remote control

-

The fan adopts PLC+GPRS control technology. It not only realizes the overall central control of the fan operation, but also realizes remote monitoring of the entire operation status of the fan . Once the fan fails, it can be immediately discovered and corresponding measures can be taken for remote maintenance and debugging. At the same time, it also has storage, memory and remote acquisition control functions.

05

Performance comparison with other blowers

In order to facilitate everyone's comparison, it is specially displayed in table form:

|

index |

Magnetic levitation blower |

Roos |

Single stage centrifugal blower |

air suspension blower |

|

Vibration comparison |

very small |

Very big |

Small and medium |

very small |

| Noise comparison |

75-85 decibels, no sound isolation cover required |

Above 100 decibels, a sound isolation cover is required | 90-100 decibels, sound isolation cover required | 75-85 decibels, no sound isolation cover required |

|

Air volume adjustment |

30-100% |

Adjustable, need to install frequency converter |

50-100% |

65-100% |

|

device installation |

Low weight and easy to install |

Heavy weight, need to be hoisted |

Heavy weight, need to be hoisted | Low weight and easy to install |

| Service life |

More than 20 years |

5-8 years |

about 10 years |

about 10 years |

|

Lubrication system |

No lubrication required |

Need lubrication |

Lubrication is complex |

No lubrication required |

| size |

small volume |

Larger in size |

Larger in size |

small volume |

|

Maintenance method |

Regular filter replacement reduces maintenance and costs |

Regular maintenance, many wearing parts |

Regular maintenance by dedicated personnel requires many wearing parts, heavy workload, and high cost. |

Regular filter replacement, low maintenance |

|

Can it be started frequently? |

Can |

Can |

Can |

Can't |

In general, Roots blowers are suitable for treatment equipment with smaller flow rates within 100m3/min . Their energy consumption is not much different from that of centrifugal blowers. They have good flow control, high efficiency in changing water levels, and low prices. They are mainly used for small municipal sewage and Factory sewage treatment, especially sewage treatment plants suitable for CAST process .

Single-stage high-speed centrifugal blowers cannot adopt variable frequency speed regulation. They are highly efficient at full load . However, when the flow rate decreases, the power consumption does not decrease year-on-year. Therefore, the efficiency at part load is low and the energy consumption is large. It is mainly suitable for large and medium-sized sewage plants. .

Magnetic levitation centrifugal blowers and air levitation centrifugal blowers have the advantages of high efficiency, energy saving, low noise, and no vibration. However, the one-time investment cost is high , but in the long-term operation process, it can save power consumption and maintenance costs , and can be used as the future sewage treatment industry. the main development direction.

06

Conclusion

At present, most of the secondary biological treatment stages of sewage treatment use a blower bottom aeration process, so the choice of blower will directly affect investment and long-term benefits. As one of the commonly used equipment for sewage treatment in the future, the magnetic levitation blower can meet the needs of modern society for sewage treatment in terms of equipment operation and energy saving and emission reduction. Therefore, it is necessary to strengthen the research on magnetic levitation blowers in sewage treatment to further improve stability and reduce costs, so that their applications will be more extensive in the future!

XINDA

XINDA