Why should an encoder be installed on the motor? how to work?

During the operation of the motor, parameters such as current, rotation speed, and the relative position of the rotating shaft in the circumferential direction are monitored in real time to determine the status of the motor body and the dragged equipment, and further control the operating conditions of the motor and equipment in real time, thereby realizing many specific functions such as servo and speed regulation. Function.

Here, the application of encoders as front-end measurement components not only greatly simplifies the measurement system, but is also precise, reliable, and powerful.

An encoder is a rotary sensor that converts the position and displacement physical quantities of rotating parts into a series of digital pulse signals. These pulse signals are collected and processed by the control system, and a series of instructions are issued to adjust and change the operating status of the equipment. If the encoder is combined with a gear rack or screw screw, it can also be used to measure the position and displacement physical quantities of linear moving parts.

Encoder

Basic classification of encoders

An encoder is a precision measuring device that closely combines mechanics and electronics. It encodes and converts signals or data for communication, transmission and storage of signal data. According to different characteristics, the encoder classification is as follows:

● Code disc and code ruler: The encoder that converts linear displacement into electrical signals is called a code ruler, and the encoder that converts angular displacement into telecommunications is called a code disc.

● Incremental encoder: Provides information such as position, angle and number of revolutions, and defines the resolution in terms of the number of pulses per revolution.

● Absolute encoder: Provides position, angle, number of turns and other information in angle increments, with each angle increment assigned a unique code.

●Hybrid absolute encoder: The hybrid absolute encoder outputs two sets of information: one set of information is used to detect the magnetic pole position, with absolute information function; the other set is exactly the same as the output information of the incremental encoder.

●Incremental encoder

Directly utilize the principle of photoelectric conversion to output three sets of square wave pulses A, B and Z phases. The phase difference between the two sets of A and B pulses is 90o, which can easily determine the direction of rotation; one pulse for each rotation of the Z phase is used for reference point positioning. Its advantages: simple principle and structure, average mechanical life of more than tens of thousands of hours, strong anti-interference ability, high reliability, and suitable for long-distance transmission. Disadvantages: Unable to output absolute position information of shaft rotation.

●Absolute encoder

A sensor that directly outputs digital quantities. There are a number of concentric code tracks along the radial direction on the circular code disk of the sensor. Each track is composed of light-transmitting and opaque sector-shaped areas. The number of sectors in adjacent code channels is doubled. , the number of code tracks on the code wheel is the number of binary digits. On one side of the code wheel is a light source, and on the other side there is a photosensitive element corresponding to each code track; when the code wheel is in different positions, each photosensitive element Whether it is illuminated or not is converted into a corresponding level signal to form a binary number.

The characteristic of this encoder is that it does not require a counter, and a fixed digital code corresponding to the position can be read at any position on the rotating shaft. Obviously, the more code channels, the higher the resolution. For an encoder with N-bit binary resolution, the code disk must have N bar code channels. At present, there are 16-bit absolute encoder products in China.

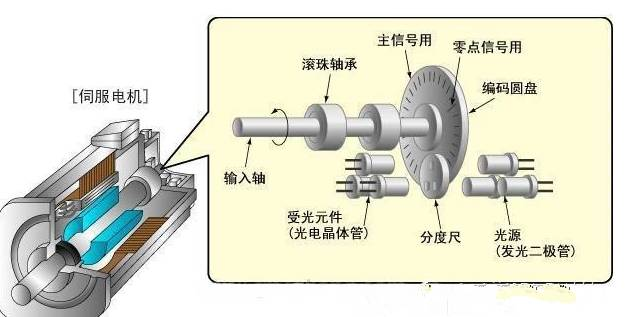

It consists of a photoelectric code disk with an axis in the center, with annular open and dark engraved lines on it, and is read by photoelectric transmitting and receiving devices. Four sets of sine wave signals are obtained and combined into A, B, C, and D. Each sine wave is With a phase difference of 90 degrees (360 degrees relative to one cycle), the C and D signals are reversed and superimposed on the A and B phases to enhance the stable signal; in addition, a Z phase pulse is output for each revolution to represent the zero reference Bit.

Encoder structure

Since the A and B phases are 90 degrees apart, the forward and reverse rotation of the encoder can be determined by comparing whether phase A is in front or phase B is in front. Through the zero pulse, the zero reference position of the encoder can be obtained.

The materials of the encoder code disc include glass, metal, and plastic. The glass code disc is deposited with very thin engraved lines on the glass. It has good thermal stability and high precision. The metal code disc is directly engraved with pass and non-pass lines and is not easy to break. However, since metal has a certain thickness, its accuracy is limited, and its thermal stability is an order of magnitude worse than that of glass. Plastic code discs are economical and have low cost, but their accuracy, thermal stability, and lifespan are poorer. .

Resolution - The number of clear or dark lines that the encoder provides per 360 degrees of rotation is called resolution, also known as analytical graduation, or directly called how many lines, generally between 5 and 10,000 lines per revolution.

Encoder

Encoders occupy an extremely important position in elevators, machine tools, material processing, motor feedback systems, and measurement and control equipment. The encoder uses gratings and infrared light sources to convert optical signals into TTL (HTL) electrical signals through the receiver. By analyzing the TTL level frequency and the number of high levels, it intuitively reflects the rotation angle and position of the motor.

Since both angle and position can be measured accurately, the encoder and frequency converter can be combined into a closed-loop control system to make the control more precise. This is why elevators, machine tools, etc. can be used so accurately.

To sum up, we understand that encoders are divided into incremental and absolute types according to their structure. They also convert other signals, such as optical signals, into electrical signals that can be analyzed and controlled.

The common elevators and machine tools in our lives are all based on the precise regulation of motors. Through the feedback closed-loop control of electrical signals, the encoder and the frequency converter naturally achieve precise control.

XINDA

XINDA