Explain the key knowledge of explosion-proof motors

1. Reasons to consider for explosion protection

Explosive substances: Many production sites produce certain flammable substances. Explosive substances exist in about two-thirds of underground coal mines; in the chemical industry, explosive substances exist in more than 80% of production workshop areas.

Oxygen: Oxygen is everywhere in the air.

Ignition source: A large number of electrical instruments are used in the production process. Various friction sparks, mechanical wear sparks, static sparks, high temperatures, etc. are inevitable, especially when instruments and electrical failures occur. Objectively speaking, many industrial sites meet explosion conditions. When the mixed concentration of explosive substances and oxygen is within the explosion limit range, if an explosion source exists, an explosion will occur. Therefore, it is necessary to take explosion protection.

2. Basic knowledge of explosion-proof motors

An explosion-proof motor is a type of motor that can be used in flammable and explosive places and does not produce sparks during operation. Explosion-proof motors are mainly used in coal mines, oil and gas, petrochemical and chemical industries. In addition, it is also widely used in textile, metallurgy, city gas, transportation, grain and oil processing, papermaking, medicine and other sectors. As the main power equipment, explosion-proof motors are usually used to drive pumps, fans, compressors and other transmission machinery.

1. Explosion-proof motors are generally used in flammable and explosive situations.

2. The sealing of the explosion-proof motor junction box is better than that of ordinary motors.

3. The minimum protection level of explosion-proof motors is IP55, while ordinary motors have IPIP23, IP44, IP54, IP55, and IP56, so they can be distinguished from the appearance.

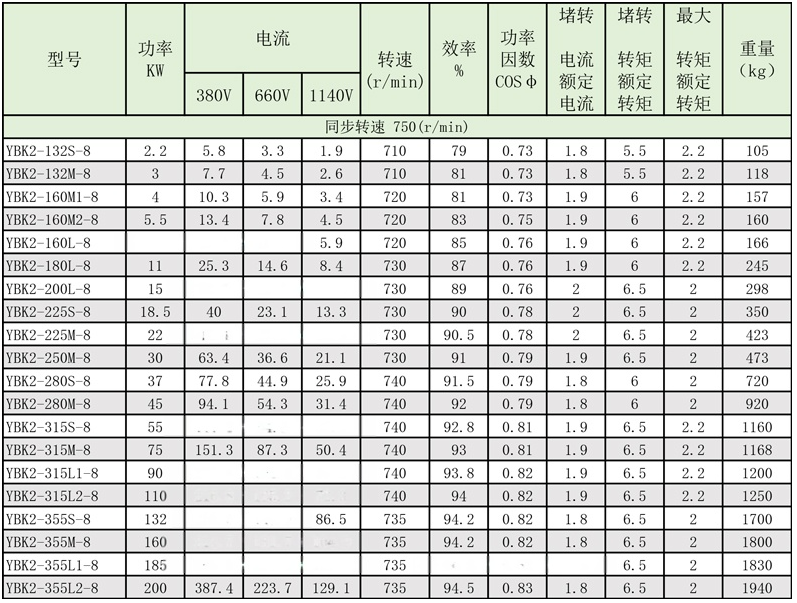

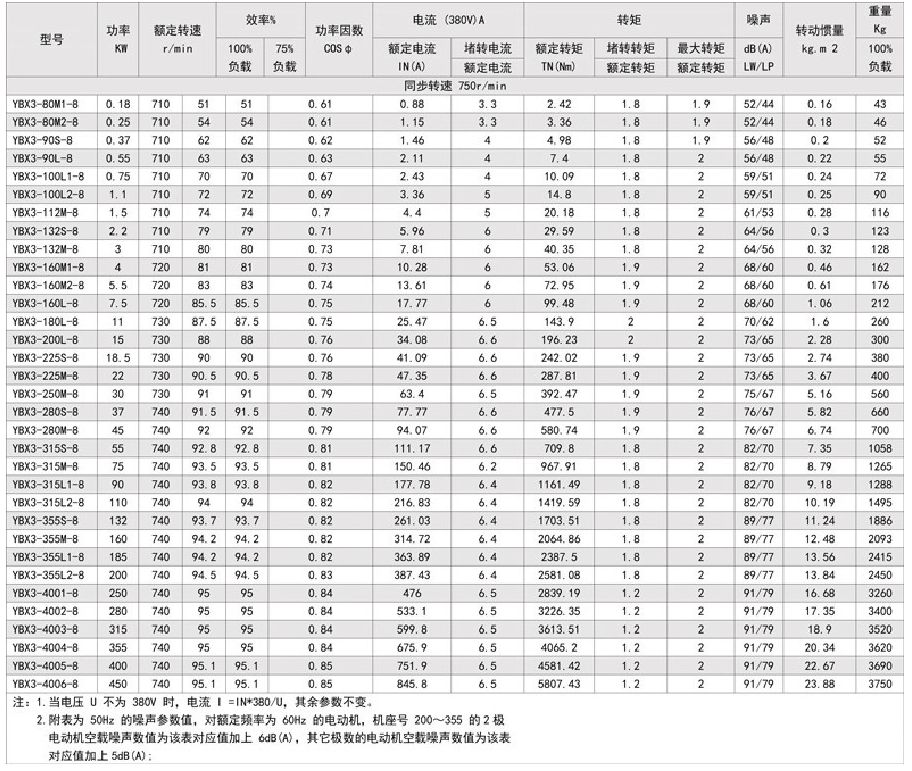

The following are explosion-proof motor models and technical parameters.

1. Explosion-proof motor model military summer camp

B- stands for "explosion-proof";

X- stands for "Energy Efficient"

2-Product design serial number, indicating the second design;

3-Product design serial number, indicating the third design;

YB- stands for "flameproof asynchronous motor";

A-represents the "safe" type;

K- product feature code, indicating special use in mines;

YA- represents increased safety asynchronous motor;

F- stands for "ventilation" and "dust", for example, YBF stands for flameproof asynchronous motor for fans, and YFB stands for dust explosion-proof motor;

S- stands for "water" cooled, "conveying" conveyor motors, such as YBS stands for flameproof asynchronous motors for conveyors, and YBSS stands for water-cooled flameproof asynchronous motors for conveyors.

2. Explosion-proof grade of explosion-proof motor: ExdI, ExdII BT4, ExdII CT4, ExtD B21;

3. Protection level of explosion-proof motor: IP55, the first 5-finger dustproof level; the second 5-finger waterproof level. Protection levels include IP44, IP54, IP55 (standard protection level for EXDI and ExdII BT4BT4), IP65 (standard protection level for ExdII CT4 and ExtD B21), IP56, etc.;

4. Insulation grade of explosion-proof motor: Class F;

5. Installation method of explosion-proof motor: B3 (horizontal foot link); B5 (vertical flange connection); B35 (vertical and horizontal use, both with foot flange); V1 (flange connection motor Shaft head downward);

6. Frame number of explosion-proof motor: The center height distance is the vertical height of the motor shaft extension from the ground;

7. The relationship between the rotation speed of the explosion-proof motor and the number of poles, unit: r/min: the rotation speed of the 2-pole (P) explosion-proof motor is 3000r/min; the rotation speed of the 4-pole (P) explosion-proof motor is 1500r/min; 6P ( The rotation speed of the explosion-proof motor is 1000r/min; the rotation speed of the 8P (pole) explosion-proof motor is 750r/min; the rotation speed of the 10-pole (P) explosion-proof motor is 600r/min;

8. Explosion-proof motor base length: M: base length (S=short, M=medium, L=long);

9. Explosion-proof motor design serial number: indicates which modification design the explosion-proof motor belongs to;

3. Common fault types of explosion-proof motors

1. Damage to explosion-proof surface

The explosion-proof surface is also called the explosion-proof surface. Damage to this part will seriously affect the explosion-proof effect of the explosion-proof motor. Generally speaking, there are many reasons for damage to explosion-proof surfaces, which may occur during the production process, assembly process and use. It may also be due to failure to operate according to relevant technical regulations during daily repair and maintenance, resulting in damage to the explosion-proof surface. In addition, condensation inside the motor is easy to occur in a humid environment. If not properly resolved at this time, it will also lead to corrosion of the explosion-proof surface.

2. Phase loss operation

When a phase loss occurs, the motor can still rotate, but it is easy for the current to exceed the normal value. If the problem cannot be found and solved in time, it will lead to motor overheating, control circuit equipment failure, cable phase loss and burnt out, etc.

3. Three-phase current imbalance

Current imbalance may occur during the use of explosion-proof motors, which will lead to a decrease in the operational stability of the equipment. Generally speaking, this problem is mainly related to the voltage stability of the three-phase power supply and the number of three-phase turns. Unbalanced three-phase loads will increase the operating energy consumption of the equipment, affect the insulation performance of the motor, and also risk burning the windings.

4. No-load current is too large

During the operation of explosion-proof motors, the current needs to be designed based on actual operating conditions. Normally, the no-load current of the equipment is related to the number of pole pairs of the motor, the magnetically permeable material and the motor power. In actual use, the current often exceeds 50%. At this time, the no-load current is high, which poses a certain high risk of use. There will also be a problem where the rated current is lower than 20%. At this time, the no-load current is low, which easily affects the operating effect of the equipment and is not conducive to the requirements of operational stability.

4. Common faults and maintenance optimization strategies of explosion-proof motors

Routine maintenance and management of explosion-proof motors are necessary to ensure the scientific operation of the equipment. During daily maintenance, the most critical link is to provide a good working environment and reduce the risk of various problems on the motor's flameproof surface as much as possible to ensure the contact effect of the contact surface.

2. Establish a complete maintenance system

Establishing a complete maintenance system also plays a certain role in the scientific operation of explosion-proof motors. Build a management file for explosion-proof motors within the enterprise, record the maintenance and repair history of explosion-proof motors, evaluate the operating status, formulate a complete maintenance management plan, strengthen the motor pre-inspection management model, nip failures in the bud, and ensure Operational reliability of explosion-proof motors.

XINDA

XINDA