Selection of motor power

The capacity calculation and verification of the motor are relatively complicated. The calculation of the load torque of the motor takes into account many factors, and it is difficult to obtain the load diagram of the motor. In practical engineering applications, statistical methods and analogy methods are often used. The statistical method is to statistically analyze the capacity of the motors selected for the same type of equipment, find out the relationship between the motor capacity and the main parameters of the production machinery, determine the corresponding index according to the actual situation, and obtain the corresponding calculation formula for the motor capacity. The analogy method refers to investigating the capacity of motors used in similar production machinery that have been tested for a long time, and making analogies with the main parameters and working conditions of the production machinery and motors to determine the capacity of the motor selected for the new production machinery.

The steps for selecting the rated power (capacity) of the motor are: first calculate the load power; then pre-select the rated power of the motor based on the load power; and finally verify the heat generation, overload capacity and starting capacity until it is suitable.

1. Selection of rated power of continuous working motor

1.1 Selection of motor power under constant load (S 1 ) continuous working system

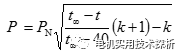

The selection of motor power for production machinery working under continuous constant load is relatively simple. Since continuous working motors are designed according to continuous constant load, only P Z ≦ P N can keep the temperature rise from exceeding the allowable value. According to the load power , just select a motor in the product catalog with a rated power equal to or slightly greater than the load power and a suitable speed. No thermal verification is required. Capacity selection steps: 1 ) Calculate the load power P Z first ; 2 ) Press P Z to select the motor so that P N ≥ P Z ; 3 ) Verify the starting ability of the selected motor. 4 ) If the ambient temperature t 0 is different from the standard

In the formula:  is the ratio of the no-load loss (constant loss) of the motor to the variable loss of the rated load. For a cage-type three-phase asynchronous motor, its value is 0.5~0.7 according to the motor structure and the number of poles ; t∞ is the insulation The maximum allowable temperature of the material. Table 2 is a correction range table for motor power selection under different ambient temperatures.

is the ratio of the no-load loss (constant loss) of the motor to the variable loss of the rated load. For a cage-type three-phase asynchronous motor, its value is 0.5~0.7 according to the motor structure and the number of poles ; t∞ is the insulation The maximum allowable temperature of the material. Table 2 is a correction range table for motor power selection under different ambient temperatures.

Table 2 Correction values for motor power selection under different ambient temperatures

|

ambient temperature |

|

|

|

|

|

|

|

Motor power increase or decrease |

+8% |

+5% |

0 |

-5% |

-12.5% |

-25% |

1.2 Selection of rated power of continuous working motor with changing load ( S 6 ~ S 9 )

The changing load working system includes the continuous periodic working system S 6 , the continuous periodic working system with electric braking S 7 , the continuous periodic working system with variable speed and load S 8 , and the non-periodic changing load and speed working system S 9 .

The temperature rise of a motor operating under varying loads is not only related to the size of the load, but also to the duration of the load power. The average power P zd of production machinery can only reflect the average temperature rise of the motor, so preselect the rated power of the motor according to P N = (1.1~1.6) P zd . The motor operates under changing loads, and its output power changes constantly, and the internal losses of the motor and temperature rise are also constantly changing. At this time, if the motor power is selected according to the maximum load power, the motor will not be fully utilized; if the motor power is selected according to the minimum load power, the motor will be overloaded, which will cause the motor temperature to rise too high. Therefore, the selection of motor rated power under changing loads is more complicated, and is generally carried out according to the following steps: 1 ) Pre-selection of motor rated power; 2 ) Verification of motor rated power; 3 ) Correction of motor rated power; 4 ) Overload capacity and starting Verification of ability. 5 ) Calculate the temperature rise change curve of the motor and obtain the maximum temperature rise θ max . The power of the motor working under changing loads should be selected according to the duration of large loads. If the large load runs for a long time, a larger coefficient should be selected. If the small load runs for a long time, a smaller coefficient should be selected, and the motor should be calibrated .

2. Selection of motor rated power for intermittent working system (S 2 ~S 5 )

Intermittent duty motors include short-time duty S 2 , intermittent period duty S 3 , intermittent duty duty S 4 including starting, and intermittent duty duty S 5 with electric braking .

2.1 Selection of motor power under short-time working system (S 2 )

For short-time working loads, a dedicated short-time working motor should be used. In the absence of a dedicated motor, a continuous working motor can also be used. 1 ) Directly choose a short-time working motor. The motor manufacturer has specially designed and manufactured short-time working motors for short-time working production machinery. Its time specifications are: 15min , 30min , 60min , and 90min . When the working time is close to the above standard time, you can directly select it from the product catalog according to the power, working time and speed requirements of the production machinery. When the working conditions do not correspond, the equivalent power method can be used to perform conversion according to the formula P 2 t = P s 2 t s , where P s and t s are the actual power and running time of the selected motor, and P and t are Actually choose a motor with similar power and running time. 2) Use continuous working system motors. Since the production of short-time working system motors is small, continuous working system motors are sometimes selected to replace short-time working system motors in production. If you choose a motor with a continuous working system and use a normal motor with the same power, the motor will not be fully utilized in terms of heat generation. For this reason, you can choose a motor with a smaller power to allow the motor to run overloaded for a short time during the working time. The basis for selecting the motor power at this time is: within a short working time, the temperature rise reached by the motor overload operation should be slightly less than the maximum allowable temperature rise of the motor. Because the motor has a short working time and a long downtime. When preselecting the motor, the load power for short-time operation should be converted into the load power for continuous operation.

2.2 Selection of motor power under intermittent cycle working system (S 3 ~S 5 )

There are four standard load duration rates of motors under the intermittent cycle working system: 15% , 25% , 40% , and 60% . The same motor has different rated output powers under different load duration rates. The smaller the load duration rate, the greater the rated power allowed for short-term output, that is, P 15% >P 25% >P 40% >P 60% . The steps for power selection of intermittent duty cycle motors are similar to those for continuous duty duty under variable loads. It requires pre-selection of the motor and calibration. In general, the motor should be pre-selected based on the load duration of the production machinery. At the same time, the impact of electric braking on temperature rise must be considered for the intermittent cycle working system S 4 including starting and the intermittent cycle working system S 5 with electric braking. According to experience, when the overload capacity and mechanical structural strength are satisfied, the allowable overload multiples when selecting a continuous duty motor for an intermittent duty cycle motor are shown in Table 3 . When the load duration rate of the motor in the intermittent duty cycle is less than 10% , the short-time duty cycle is used, and the load duration rate is greater than 70% , and the motor power is selected in the continuous duty cycle.

Table 3 Allowable overload multiples for S1 working system motors in intermittent cycle working system

|

load duration |

S 3 |

S 4 or S 5 |

|

15% |

1.8 |

-- |

|

25% |

1.6 |

1.3 |

|

40% |

1.4 |

1.15 |

|

60% |

1.15 |

1 |

According to the characteristics of short-time and periodic working systems, the temperature rise at the end of the motor's operation is designed to be close to the maximum allowable temperature rise of the insulation material. Then when the motor is pulling a load and working, the stable temperature rise will not exceed the maximum allowable temperature of the motor. Lift. However, when the motor is driving a continuous load of the same size, the stable temperature rise will greatly exceed the maximum allowable temperature rise of the motor, and the motor will be burned out. The same short-time or periodic working motor has different nominal rated power and overload multiples corresponding to different working times.

3. Conclusion:

Principle of motor power selection: It can meet the production machinery's power, torque, speed, starting, speed regulation, braking and overload requirements of the motor, so that the motor can be fully utilized during operation, and its temperature rise does not exceed but is close to The temperature rise of insulation is stipulated in national standards to extend the life of the motor and ensure the normal operation of the equipment.

XINDA

XINDA