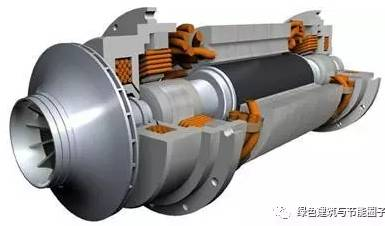

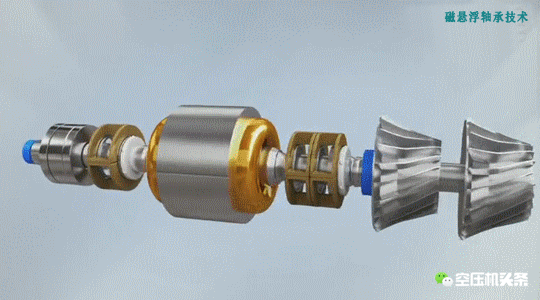

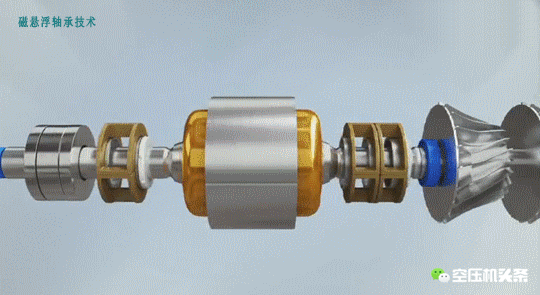

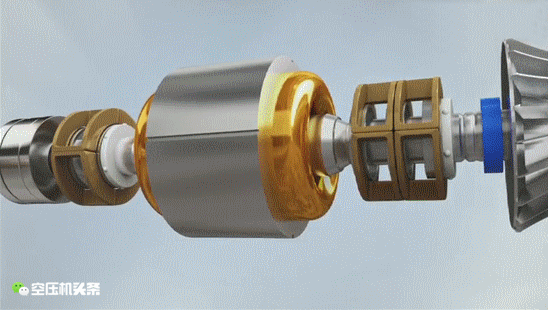

Since the 1990s, magnetic levitation technology has been applied to bearings, bringing special advantages such as no contact, no friction, long life, no lubrication and high precision. Scholars and business people at home and abroad have devoted great efforts to it. Interest and enthusiasm for research.Compared with traditional rolling bearings, sliding bearings and oil film bearings, magnetic suspension bearings have no mechanical contact, and the rotor can run to a high speed, with small wear, low energy consumption, low noise, long life, no lubrication, no oil pollution, etc. advantage.Especially suitable for high-speed, vacuum, ultra-clean and other environments.In fact, magnetic levitation is only an auxiliary function of bearings, not a form of bearings. Specific applications also need to cooperate with other bearing forms, such as magnetic levitation + ball bearings, magnetic levitation + oil bearings, magnetic levitation + vaporization bearings, etc.High speed magnetic levitation motorIt is a popular new research direction in recent years. It integrates magnetic suspension bearings and motors, has self-suspension and driving capabilities , does not require any independent bearing support, has the characteristics of small size and high critical speed, and is more suitable for ultra-high-speed operation occasions. , also suitable for small and even ultra-small structures.

Since the mid-1990s, researches have been carried out abroad, and various types of permanent magnet synchronous magnetic levitation motors, switched reluctance magnetic levitation motors, and induction magnetic levitation motors have appeared one after another.

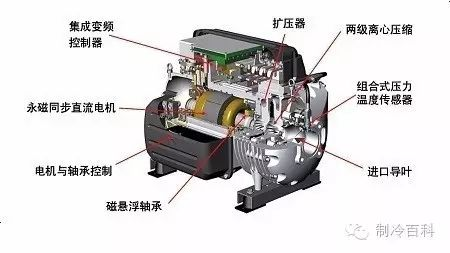

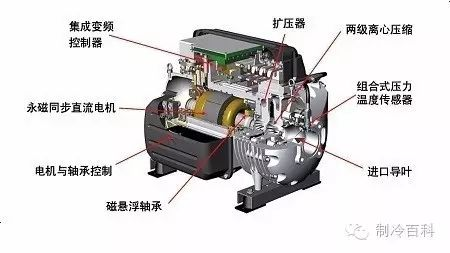

Magnetic levitation high-speed motors are mainly used in centrifugal compressors. This is because centrifugal compressors require a high speed. In order to achieve high speeds, traditional centrifuges not only require huge high-precision gear transmissions, but also require complex oil lubrication systems, Oil sealing system and so on.The use of magnetic levitation high-speed motors perfectly avoids these unfavorable factors. Through the magnetic levitation technology combined with permanent magnets and electromagnetics, the centrifuge shaft can be in a relatively perfect six-sided volley state.

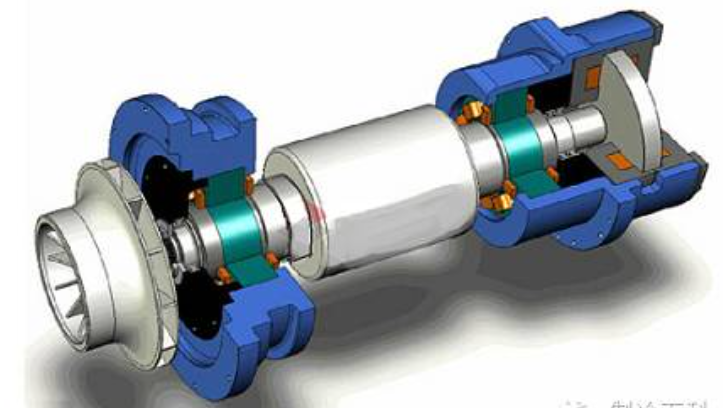

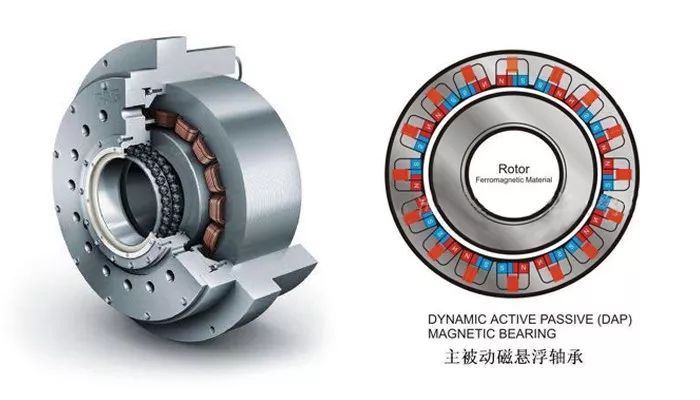

Magnetic refrigeration centrifugal compressors were first developed. In 2003, the world's first magnetic levitation compressor was born. In 2006, China's first magnetic levitation centrifugal compressor central air conditioner was launched.At present, domestic magnetic levitation centrifugal compressor application technology is not very mature, and most of the core components of magnetic levitation refrigeration centrifugal compressors come from foreign companies, such as Danfoss.Magnetic Levitation Centrifuge - Radial Bearing

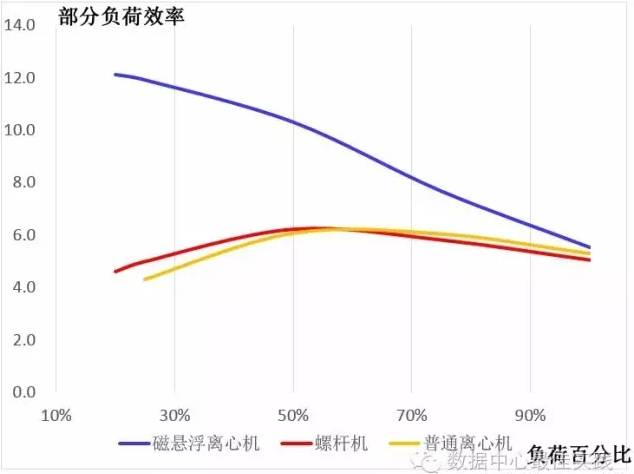

Magnetic Levitation Centrifuge - Axial BearingMagnetic Levitation Centrifuge - Positioning SensorMagnetic levitation centrifuge - motor and drive shaftOil-free magnetic levitation centrifugal compressors and oil-free magnetic levitation blowers are the main application directions of magnetic levitation in air compressors.There are currently very few domestic companies involved in oil-free centrifugal compressors with common pressures, mainly because there is still a technical gap.Foreign brands are leading the way in this regard, such as the magnetic levitation variable frequency centrifuge Quantima launched by Compair in 2010, with a flow and pressure range covering 3~8bar and 28~70m³/min.At present, air compressor companies in the domestic market, including Atlas, have launched magnetic levitation single-stage centrifugal blowers , targeting the market that replaces a large number of Roots blowers.

The design of the impeller and other units of the single-stage centrifugal blower is very mature in China and is relatively difficult. The core of the technology is the magnetic suspension bearing. Most of the magnetic levitation centrifugal blowers launched by domestic air compressor companies are only OEM or assembled, and most of the technology sources come from South Korea's Shia.Interestingly, the localization of magnetic levitation bearings does not come from within the air compressor industry, but from outside the industry. The well-known domestic independent magnetic levitation bearing technologies include: Tianjin Yisheng, Zhejiang Feixuan, Nanjing Magnetic Valley, etc. The technology sources include Tsinghua University and Southwest Jiaotong University.

But to be honest, fans and pumps are traditionally in the same industry segment, and the sales channels and models are quite different from those of air compressors.

In the final analysis, magnetic levitation centrifugal blowers are still in the category of fans. When air compressor companies develop this market, they are not only faced with the problem of explaining new products, but also facing unfamiliar channels, unfamiliar user markets, unfamiliar models, as well as fans and Serious .

XINDA

XINDA